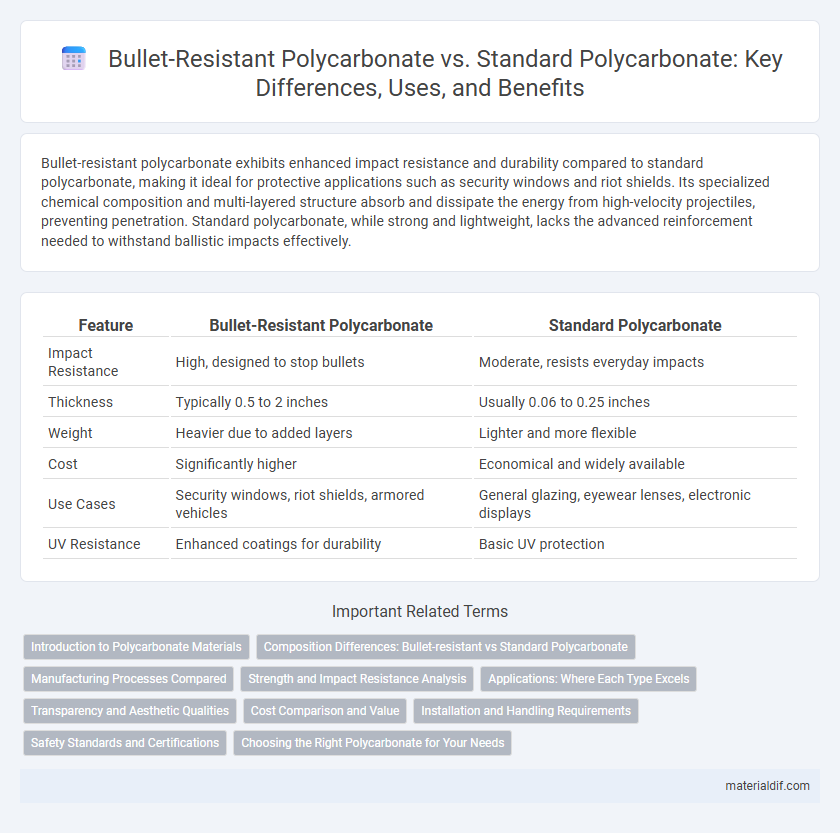

Bullet-resistant polycarbonate exhibits enhanced impact resistance and durability compared to standard polycarbonate, making it ideal for protective applications such as security windows and riot shields. Its specialized chemical composition and multi-layered structure absorb and dissipate the energy from high-velocity projectiles, preventing penetration. Standard polycarbonate, while strong and lightweight, lacks the advanced reinforcement needed to withstand ballistic impacts effectively.

Table of Comparison

| Feature | Bullet-Resistant Polycarbonate | Standard Polycarbonate |

|---|---|---|

| Impact Resistance | High, designed to stop bullets | Moderate, resists everyday impacts |

| Thickness | Typically 0.5 to 2 inches | Usually 0.06 to 0.25 inches |

| Weight | Heavier due to added layers | Lighter and more flexible |

| Cost | Significantly higher | Economical and widely available |

| Use Cases | Security windows, riot shields, armored vehicles | General glazing, eyewear lenses, electronic displays |

| UV Resistance | Enhanced coatings for durability | Basic UV protection |

Introduction to Polycarbonate Materials

Polycarbonate materials are high-performance thermoplastics known for their exceptional impact resistance and optical clarity, making them ideal for various applications. Bullet-resistant polycarbonate is engineered with increased thickness and specific chemical additives to enhance its ability to absorb ballistic impacts, surpassing the durability of standard polycarbonate sheets. Standard polycarbonate offers versatility and toughness for everyday uses such as glazing and automotive components but lacks the specialized reinforcement required for ballistic protection.

Composition Differences: Bullet-resistant vs Standard Polycarbonate

Bullet-resistant polycarbonate contains a higher molecular weight and specialized additives such as elastomeric interlayers and impact modifiers, enhancing its ability to absorb and disperse kinetic energy upon impact. Standard polycarbonate primarily consists of basic thermoplastic polymers without reinforced layers, making it less effective against ballistic threats. The compositional enhancements in bullet-resistant polycarbonate significantly improve tensile strength, impact resistance, and energy absorption compared to standard polycarbonate.

Manufacturing Processes Compared

Bullet-resistant polycarbonate undergoes a specialized manufacturing process involving multi-layer lamination and the incorporation of high-strength polymers to enhance impact resistance, unlike standard polycarbonate which is produced through single-layer extrusion or injection molding. The lamination process in bullet-resistant variants includes bonding multiple polycarbonate sheets with interlayers that absorb and dissipate kinetic energy from projectiles. Standard polycarbonate manufacturing emphasizes clarity and durability for general use, whereas bullet-resistant production prioritizes ballistic performance through controlled thickness and material composition.

Strength and Impact Resistance Analysis

Bullet-resistant polycarbonate exhibits significantly higher tensile strength and impact resistance compared to standard polycarbonate, making it ideal for security applications. The material's reinforced molecular structure enables it to absorb and dissipate the energy from high-velocity projectiles without fracturing. Standard polycarbonate, while strong and flexible, lacks the enhanced laminate layers that provide the bullet-resistant variant with superior ballistic resistance.

Applications: Where Each Type Excels

Bullet-resistant polycarbonate is engineered for high-impact scenarios requiring enhanced security, making it ideal for military vehicles, protective barriers, and secure facility windows. Standard polycarbonate excels in general-purpose applications such as eyewear lenses, electronic housings, and greenhouses due to its excellent transparency and impact resistance. The choice depends on balancing cost, performance, and the level of protection required for specific uses.

Transparency and Aesthetic Qualities

Bullet-resistant polycarbonate maintains high transparency comparable to standard polycarbonate, often achieving light transmittance above 89%, ensuring clear visibility without significant distortion. Its enhanced composition includes multiple layers designed to absorb and dissipate impact energy, which slightly increases thickness but preserves aesthetic clarity, unlike traditional laminated glass. Standard polycarbonate offers excellent optical clarity with a sleek finish, yet the bullet-resistant variant balances protective performance with minimal compromise on visual appeal, making it ideal for secure environments demanding both safety and transparency.

Cost Comparison and Value

Bullet-resistant polycarbonate typically costs three to five times more than standard polycarbonate due to its specialized multi-layered structure and enhanced impact resistance. While the upfront investment is higher, bullet-resistant polycarbonate delivers superior protection for security applications, providing significant value in environments requiring ballistic safety. Standard polycarbonate remains a cost-effective choice for general use where impact resistance is needed but ballistic protection is not a priority.

Installation and Handling Requirements

Bullet-resistant polycarbonate requires specialized installation techniques involving reinforced framing systems and precise sealing to maintain its protective integrity, often demanding professional expertise. Standard polycarbonate, by contrast, is easier to handle and install with basic tools due to its lighter weight and standard thickness, allowing more flexibility in DIY applications. The heavier weight and greater thickness of bullet-resistant polycarbonate necessitate careful handling precautions to prevent damage and ensure safety during transport and installation.

Safety Standards and Certifications

Bullet-resistant polycarbonate meets stringent safety standards such as UL 752 and NIJ Level III, ensuring certified ballistic protection against multiple rounds of high-velocity ammunition. Standard polycarbonate, while impact-resistant and durable, lacks formal certifications for ballistic resistance and is primarily designed for general safety and shatter-resistance applications. The rigorous testing protocols and certifications of bullet-resistant polycarbonate provide reliable assurance for use in security-sensitive environments like banks, government buildings, and armored vehicles.

Choosing the Right Polycarbonate for Your Needs

Bullet-resistant polycarbonate offers enhanced impact resistance and multi-layered construction designed to absorb and disperse ballistic energy, making it ideal for security applications such as safes, vehicle windows, and protective barriers. Standard polycarbonate provides high strength and clarity but lacks the specialized laminations and thickness required for ballistic protection, making it suitable for general use in glazing, eyewear, and automotive components. Choosing the right polycarbonate depends on evaluating the required safety level, environmental conditions, and budget constraints to ensure optimal performance and durability in your specific application.

Bullet-resistant Polycarbonate vs Standard Polycarbonate Infographic

materialdif.com

materialdif.com