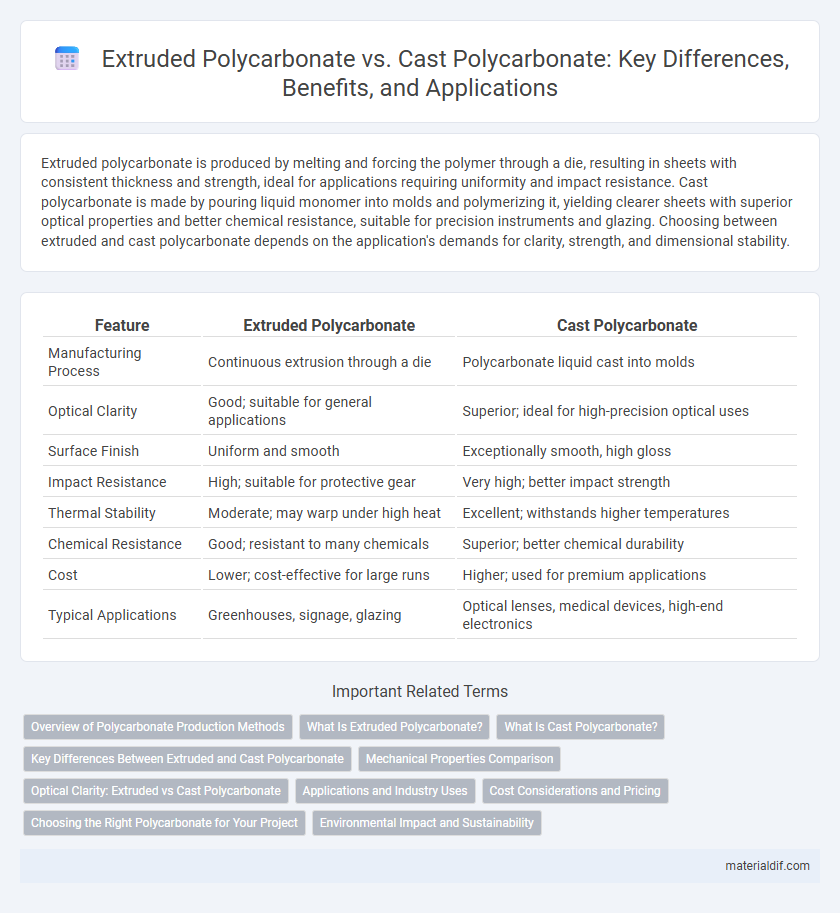

Extruded polycarbonate is produced by melting and forcing the polymer through a die, resulting in sheets with consistent thickness and strength, ideal for applications requiring uniformity and impact resistance. Cast polycarbonate is made by pouring liquid monomer into molds and polymerizing it, yielding clearer sheets with superior optical properties and better chemical resistance, suitable for precision instruments and glazing. Choosing between extruded and cast polycarbonate depends on the application's demands for clarity, strength, and dimensional stability.

Table of Comparison

| Feature | Extruded Polycarbonate | Cast Polycarbonate |

|---|---|---|

| Manufacturing Process | Continuous extrusion through a die | Polycarbonate liquid cast into molds |

| Optical Clarity | Good; suitable for general applications | Superior; ideal for high-precision optical uses |

| Surface Finish | Uniform and smooth | Exceptionally smooth, high gloss |

| Impact Resistance | High; suitable for protective gear | Very high; better impact strength |

| Thermal Stability | Moderate; may warp under high heat | Excellent; withstands higher temperatures |

| Chemical Resistance | Good; resistant to many chemicals | Superior; better chemical durability |

| Cost | Lower; cost-effective for large runs | Higher; used for premium applications |

| Typical Applications | Greenhouses, signage, glazing | Optical lenses, medical devices, high-end electronics |

Overview of Polycarbonate Production Methods

Extruded polycarbonate is produced by melting plastic pellets and forcing them through a die to form continuous sheets, resulting in cost-effective, uniform thickness with good impact resistance. Cast polycarbonate involves pouring liquid resin into molds and curing it slowly, offering superior optical clarity, chemical resistance, and dimensional stability but at higher production costs. These distinct manufacturing techniques influence the material's mechanical properties, surface finish, and applications in industries like automotive, construction, and electronics.

What Is Extruded Polycarbonate?

Extruded polycarbonate is produced by melting polycarbonate pellets and forcing the molten material through a die to create continuous sheets with consistent thickness and mechanical properties. This manufacturing process results in cost-effective, lightweight sheets ideal for applications in glazing, roofing, and protective barriers. Extruded polycarbonate offers good impact resistance, UV protection, and clarity, making it suitable for industrial and architectural uses.

What Is Cast Polycarbonate?

Cast polycarbonate is produced by pouring a liquid resin into molds where it hardens, resulting in sheets known for superior optical clarity and uniform thickness. This manufacturing process enhances impact resistance and thermal stability compared to extruded polycarbonate. Cast polycarbonate is commonly used in applications requiring high precision, such as aerospace windows, medical devices, and optical lenses.

Key Differences Between Extruded and Cast Polycarbonate

Extruded polycarbonate is produced by forcing the resin through a die, resulting in sheets with consistent thickness but potential internal stresses and lower optical clarity, while cast polycarbonate is formed by pouring liquid resin into molds, offering superior optical clarity, uniform thickness, and enhanced chemical resistance. Extruded sheets are generally more flexible and less expensive, making them suitable for applications requiring impact resistance and cost-efficiency, whereas cast sheets provide higher dimensional stability and surface hardness, ideal for precision optical components and high-end glazing. The choice between extruded and cast polycarbonate depends on application requirements such as optical quality, mechanical durability, and budget constraints.

Mechanical Properties Comparison

Extruded polycarbonate exhibits higher impact resistance and better weldability compared to cast polycarbonate, making it suitable for applications requiring durability and structural integrity. Cast polycarbonate typically offers superior optical clarity and chemical resistance but tends to have slightly lower tensile strength and toughness than extruded forms. The mechanical properties of extruded polycarbonate favor flexibility and strength under dynamic loads, whereas cast polycarbonate excels in precision-molded components with enhanced surface finish.

Optical Clarity: Extruded vs Cast Polycarbonate

Extruded polycarbonate typically exhibits lower optical clarity compared to cast polycarbonate due to its manufacturing process, which can introduce more internal stresses and impurities. Cast polycarbonate offers superior optical clarity with higher light transmission and reduced haze, making it ideal for applications demanding clear visual performance. This difference impacts industries such as automotive lighting and optical lenses, where precision and clarity are critical.

Applications and Industry Uses

Extruded polycarbonate offers excellent impact resistance and is widely used in applications like greenhouse panels, skylights, and protective barriers due to its lightweight and flexible properties. Cast polycarbonate provides higher optical clarity and chemical resistance, making it ideal for industries requiring precision, such as medical devices, optics, and aerospace components. Both types serve automotive and electronics sectors but differ with extruded polycarbonate favored for large-scale architectural panels and cast polycarbonate preferred for high-performance, custom parts.

Cost Considerations and Pricing

Extruded polycarbonate generally offers lower production costs and more affordable pricing compared to cast polycarbonate, making it ideal for large-volume applications. Cast polycarbonate, due to its labor-intensive manufacturing process and superior optical clarity, commands a higher price point but delivers enhanced durability and visual performance. Cost considerations depend heavily on application requirements, balancing price against quality and performance needs.

Choosing the Right Polycarbonate for Your Project

Extruded polycarbonate sheets offer consistent thickness and are cost-effective, making them ideal for large-scale applications requiring durability and flexibility. Cast polycarbonate provides superior optical clarity and chemical resistance, preferred for precision components and environments with exposure to harsh substances. Selecting the right polycarbonate depends on project needs such as budget, mechanical performance, and aesthetic requirements.

Environmental Impact and Sustainability

Extruded polycarbonate typically has a lower environmental footprint due to its energy-efficient manufacturing process, which uses continuous production and less raw material waste compared to cast polycarbonate. Cast polycarbonate involves a slower, batch process with higher energy consumption and greater emissions, impacting sustainability negatively. Recyclability rates and the potential for reuse are similar for both types, but extruded polycarbonate's streamlined production contributes to a more sustainable lifecycle overall.

Extruded Polycarbonate vs Cast Polycarbonate Infographic

materialdif.com

materialdif.com