UV-resistant polycarbonate offers superior protection against sun damage and yellowing compared to standard polycarbonate, making it ideal for outdoor applications. Its enhanced durability extends the material's lifespan by preventing degradation caused by ultraviolet rays. Standard polycarbonate, while strong and impact-resistant, lacks the protective coating that safeguards against UV exposure, leading to faster wear and discoloration.

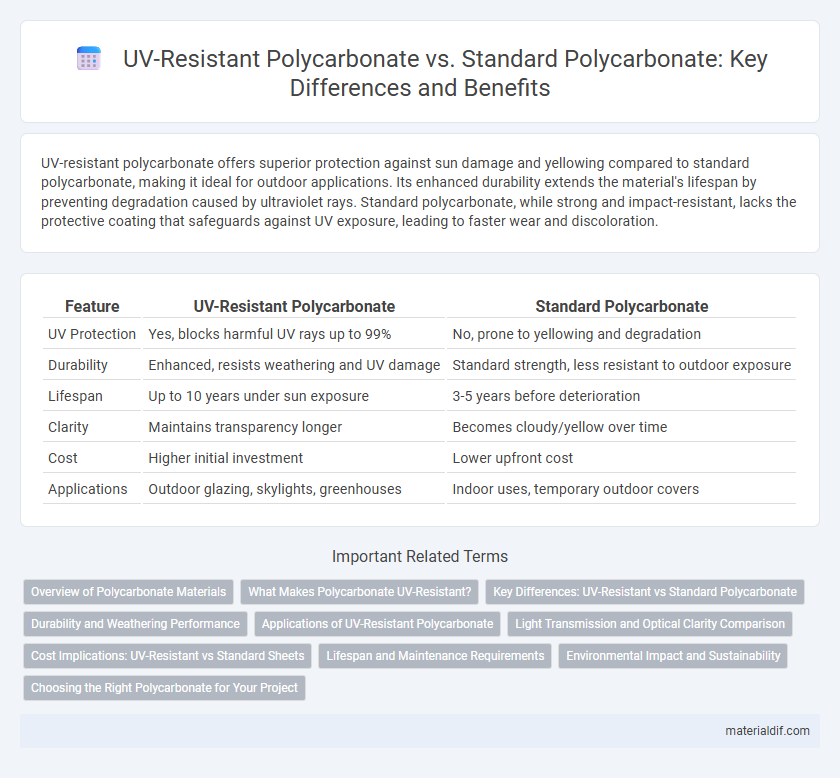

Table of Comparison

| Feature | UV-Resistant Polycarbonate | Standard Polycarbonate |

|---|---|---|

| UV Protection | Yes, blocks harmful UV rays up to 99% | No, prone to yellowing and degradation |

| Durability | Enhanced, resists weathering and UV damage | Standard strength, less resistant to outdoor exposure |

| Lifespan | Up to 10 years under sun exposure | 3-5 years before deterioration |

| Clarity | Maintains transparency longer | Becomes cloudy/yellow over time |

| Cost | Higher initial investment | Lower upfront cost |

| Applications | Outdoor glazing, skylights, greenhouses | Indoor uses, temporary outdoor covers |

Overview of Polycarbonate Materials

UV-resistant polycarbonate incorporates a specialized coating or additive that significantly enhances its ability to withstand ultraviolet radiation, preventing yellowing and degradation over time. Standard polycarbonate, while offering excellent impact resistance and transparency, tends to degrade more quickly when exposed to prolonged sunlight without this protective layer. These differences make UV-resistant polycarbonate ideal for outdoor applications, while standard polycarbonate is often suited for interior or low-UV environments.

What Makes Polycarbonate UV-Resistant?

Polycarbonate becomes UV-resistant through the incorporation of UV stabilizers or coatings that absorb and block harmful ultraviolet radiation, protecting the polymer chains from degradation. These additives enhance the material's durability by preventing discoloration, yellowing, and loss of mechanical strength caused by prolonged sun exposure. Standard polycarbonate lacks these protective elements, making it susceptible to UV-induced damage and reduced lifespan when exposed to outdoor environments.

Key Differences: UV-Resistant vs Standard Polycarbonate

UV-resistant polycarbonate contains a specialized coating or additive that significantly blocks harmful ultraviolet rays, preventing yellowing and degradation over time, while standard polycarbonate lacks this protection and is more susceptible to UV damage. The enhanced durability of UV-resistant polycarbonate makes it ideal for outdoor applications such as glazing, roofing, and protective barriers, whereas standard polycarbonate is better suited for indoor or low-UV environments. UV-resistant options maintain optical clarity and structural integrity longer, offering extended lifespan and consistent performance under prolonged sun exposure.

Durability and Weathering Performance

UV-resistant polycarbonate exhibits superior durability by incorporating UV stabilizers that prevent yellowing, brittleness, and surface degradation when exposed to prolonged sunlight. Standard polycarbonate typically degrades faster under UV radiation, resulting in reduced impact strength and clarity over time. Enhanced weathering performance in UV-resistant polycarbonate ensures longer lifespan and sustained material integrity in outdoor applications.

Applications of UV-Resistant Polycarbonate

UV-resistant polycarbonate is extensively used in outdoor applications such as greenhouse glazing, skylights, and automotive components due to its superior ability to block harmful ultraviolet rays while maintaining high impact resistance. This specialized material prevents yellowing and degradation over time, ensuring long-lasting clarity and structural integrity in environments exposed to direct sunlight. Its durability and UV protection make it ideal for architectural panels, protective covers, and signage that require sustained performance under harsh weather conditions.

Light Transmission and Optical Clarity Comparison

UV-resistant polycarbonate maintains higher optical clarity and consistent light transmission by incorporating UV stabilizers that prevent yellowing and degradation caused by prolonged sun exposure. Standard polycarbonate can experience reduced light transmission and surface hazing over time due to UV-induced polymer breakdown, leading to diminished visual performance. The enhanced durability of UV-resistant polycarbonate ensures sustained transparency, making it ideal for applications requiring long-term optical clarity.

Cost Implications: UV-Resistant vs Standard Sheets

UV-resistant polycarbonate sheets typically incur a 20-40% higher initial cost compared to standard polycarbonate due to the added protective coatings that extend their lifespan significantly. While standard polycarbonate sheets are more affordable upfront, their susceptibility to yellowing and degradation under prolonged UV exposure can lead to increased maintenance and replacement expenses over time. Investing in UV-resistant polycarbonate offers better cost efficiency in outdoor applications by reducing long-term repair and replacement frequency.

Lifespan and Maintenance Requirements

UV-resistant polycarbonate offers enhanced durability by blocking harmful UV rays that cause yellowing and brittleness, extending its lifespan up to 10-15 years compared to standard polycarbonate's typical 5-7 years. Maintenance requirements for UV-resistant polycarbonate are lower since it resists surface degradation, reducing the need for frequent cleaning and protective coatings. Standard polycarbonate requires more regular upkeep to prevent UV-related damage and maintain structural integrity over time.

Environmental Impact and Sustainability

UV-resistant polycarbonate significantly reduces environmental impact through extended product lifespan, minimizing waste and resource consumption compared to standard polycarbonate, which degrades faster under sunlight exposure. The enhanced durability of UV-resistant polycarbonate decreases the frequency of replacements and lowers the carbon footprint associated with manufacturing and disposal processes. Sustainable applications benefit from this material's ability to maintain performance without harmful additives, supporting eco-friendly building and automotive solutions.

Choosing the Right Polycarbonate for Your Project

UV-resistant polycarbonate incorporates specialized coatings or additives that block harmful ultraviolet rays, significantly extending the material's lifespan and maintaining clarity under prolonged sun exposure. Standard polycarbonate offers high impact resistance and lightweight benefits but tends to yellow and degrade faster when exposed to direct sunlight without UV protection. Selecting UV-resistant polycarbonate is essential for outdoor applications requiring long-term durability, while standard polycarbonate suits indoor or shaded environments where UV exposure is minimal.

UV-resistant Polycarbonate vs Standard Polycarbonate Infographic

materialdif.com

materialdif.com