Thermoforming polycarbonate sheets involves heating the material until pliable and shaping it over a mold, ideal for producing large, thin-walled parts with smooth surfaces and consistent thickness. Injection molding melts polycarbonate resin and injects it into a mold cavity, allowing for complex, detailed shapes and high-volume production with precise tolerances. Choosing between these methods depends on design complexity, production volume, and the desired mechanical properties of the final polycarbonate part.

Table of Comparison

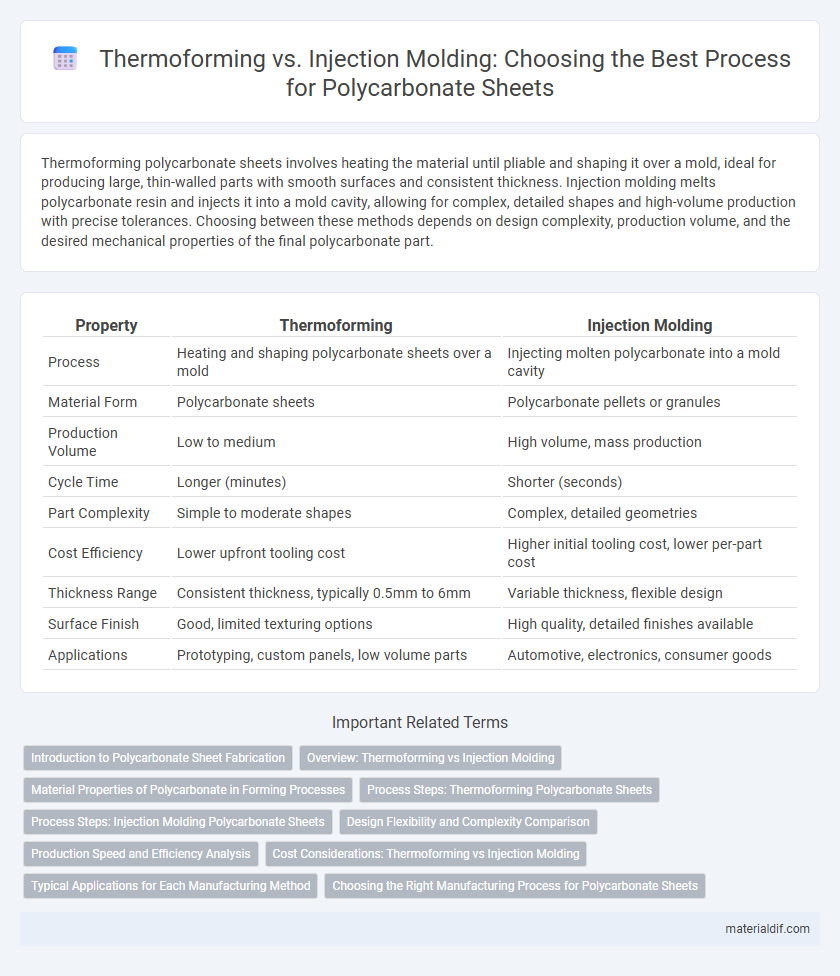

| Property | Thermoforming | Injection Molding |

|---|---|---|

| Process | Heating and shaping polycarbonate sheets over a mold | Injecting molten polycarbonate into a mold cavity |

| Material Form | Polycarbonate sheets | Polycarbonate pellets or granules |

| Production Volume | Low to medium | High volume, mass production |

| Cycle Time | Longer (minutes) | Shorter (seconds) |

| Part Complexity | Simple to moderate shapes | Complex, detailed geometries |

| Cost Efficiency | Lower upfront tooling cost | Higher initial tooling cost, lower per-part cost |

| Thickness Range | Consistent thickness, typically 0.5mm to 6mm | Variable thickness, flexible design |

| Surface Finish | Good, limited texturing options | High quality, detailed finishes available |

| Applications | Prototyping, custom panels, low volume parts | Automotive, electronics, consumer goods |

Introduction to Polycarbonate Sheet Fabrication

Polycarbonate sheet fabrication involves two primary methods: thermoforming and injection molding, each suited for distinct applications. Thermoforming heats polycarbonate sheets to a pliable state, allowing them to be shaped over molds, ideal for large, thin panels with consistent thickness. Injection molding melts polycarbonate resin pellets to form intricate, high-precision parts with complex geometries and varying thicknesses.

Overview: Thermoforming vs Injection Molding

Thermoforming polycarbonate sheets involves heating the material until pliable and then shaping it over molds, offering cost-effective, large-scale production with quick turnaround for moderate complexity parts. Injection molding of polycarbonate utilizes melting and injecting the resin into precise molds, delivering high production volumes with exceptional dimensional accuracy and complex geometries. Choosing between thermoforming and injection molding depends on factors such as part complexity, volume requirements, surface finish, and tooling costs.

Material Properties of Polycarbonate in Forming Processes

Polycarbonate's high impact resistance and excellent thermal stability make it suitable for both thermoforming and injection molding processes, though its behavior differs under each. During thermoforming, polycarbonate sheets exhibit good pliability at elevated temperatures, allowing for complex shapes without significant loss of mechanical strength. In injection molding, its viscosity and melt flow index are critical parameters that influence the precision and structural integrity of the final molded parts.

Process Steps: Thermoforming Polycarbonate Sheets

Thermoforming polycarbonate sheets involves heating the material to a pliable temperature range of approximately 300degF to 370degF (149degC to 188degC), then stretching it over a mold to achieve the desired shape. The process includes clamping the heated sheet, applying vacuum or pressure to conform it accurately to the mold surface, and cooling it rapidly to retain form and structural integrity. This method allows for efficient production of large, thin-walled components with consistent thickness, contrasting the multi-step injection molding process.

Process Steps: Injection Molding Polycarbonate Sheets

Injection molding polycarbonate sheets involves melting pellets at temperatures between 260degC and 320degC before injecting the molten material into a precision-engineered mold cavity under high pressure. The process includes clamping the mold, injecting the molten polymer, cooling the molded sheet to solidify, and then ejecting the finished part. Key advantages include high production speed, excellent dimensional accuracy, and the ability to create complex geometries with uniform thickness.

Design Flexibility and Complexity Comparison

Thermoforming polycarbonate sheets offers greater design flexibility by allowing large, continuous shapes and smooth curves with thinner wall sections, making it ideal for custom and low-volume applications. Injection molding enables higher complexity with precise, detailed features and intricate geometries but typically requires thicker walls and is more suited for high-volume production. Both methods present distinct advantages depending on the design complexity and production scale requirements of polycarbonate components.

Production Speed and Efficiency Analysis

Thermoforming polycarbonate sheets offers faster production speeds for large, simple shapes due to lower cycle times and minimal tooling complexity. Injection molding, while slower per cycle, provides higher efficiency for complex, high-volume parts by enabling rapid replication with precise detail and reduced post-processing. Manufacturers prioritize thermoforming for moderate volumes and large panels, whereas injection molding suits mass production requiring tight tolerances and intricate geometries.

Cost Considerations: Thermoforming vs Injection Molding

Thermoforming polycarbonate sheets generally incurs lower tooling costs compared to injection molding, making it more cost-effective for small to medium production runs. Injection molding requires high upfront investment in molds but offers lower per-unit costs at large volumes due to faster cycle times and automation. Evaluating production scale and complexity is essential to determine the most economical manufacturing method for polycarbonate applications.

Typical Applications for Each Manufacturing Method

Thermoforming polycarbonate sheets is ideal for producing large, lightweight parts such as protective shields, signage, and automotive panels due to its ability to create broad, relatively simple shapes efficiently. Injection molding suits complex, high-precision components like electronic housings, medical device parts, and intricate mechanical components, benefiting from its excellent dimensional accuracy and repeatability. Choosing between the two depends on part complexity, production volume, and design requirements specific to polycarbonate material properties.

Choosing the Right Manufacturing Process for Polycarbonate Sheets

Thermoforming polycarbonate sheets offers design flexibility and cost-effectiveness for medium to large parts with moderate detail, making it ideal for applications like signage and automotive components. Injection molding provides high precision and repeatability, suitable for complex, small to medium-sized polycarbonate parts requiring tight tolerances such as electronic housings and medical devices. Selecting the right manufacturing process depends on factors like part complexity, production volume, surface finish requirements, and budget constraints.

Thermoforming vs Injection molding (polycarbonate sheets) Infographic

materialdif.com

materialdif.com