Polycarbonate PET exhibits superior durability and flexibility, making it ideal for both thermoforming and cold bending processes. Thermoforming involves heating the material until pliable, allowing precise shaping without compromising structural integrity, which is excellent for complex designs. Cold bending retains the inherent strength and optical clarity of polycarbonate PET, suitable for applications requiring minimal deformation and high impact resistance.

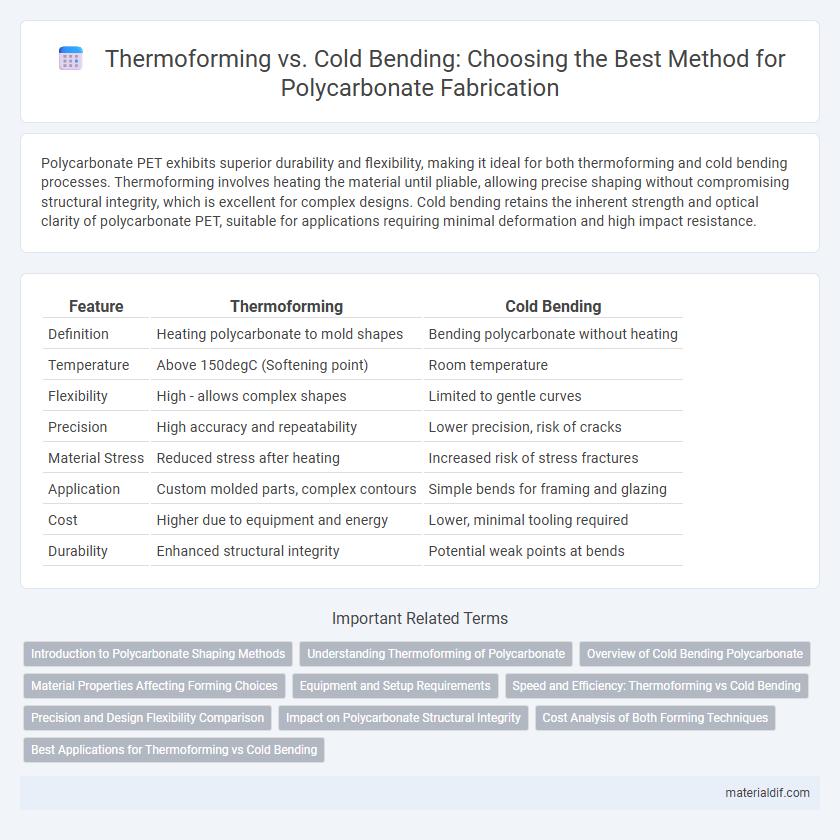

Table of Comparison

| Feature | Thermoforming | Cold Bending |

|---|---|---|

| Definition | Heating polycarbonate to mold shapes | Bending polycarbonate without heating |

| Temperature | Above 150degC (Softening point) | Room temperature |

| Flexibility | High - allows complex shapes | Limited to gentle curves |

| Precision | High accuracy and repeatability | Lower precision, risk of cracks |

| Material Stress | Reduced stress after heating | Increased risk of stress fractures |

| Application | Custom molded parts, complex contours | Simple bends for framing and glazing |

| Cost | Higher due to equipment and energy | Lower, minimal tooling required |

| Durability | Enhanced structural integrity | Potential weak points at bends |

Introduction to Polycarbonate Shaping Methods

Polycarbonate shaping methods include thermoforming and cold bending, each offering distinct advantages for different applications. Thermoforming involves heating polycarbonate sheets until pliable, enabling complex and precise shapes, ideal for mass production and architectural designs. Cold bending shapes the material at ambient temperatures, preserving impact resistance and optical clarity, suitable for curved surfaces in glazing and signage.

Understanding Thermoforming of Polycarbonate

Thermoforming polycarbonate involves heating the material to a pliable state, typically between 150degC to 180degC, allowing it to be easily molded into complex shapes without compromising its impact resistance. This process enhances design flexibility, making it ideal for applications requiring precise contours and smooth finishes, such as automotive components and protective visors. Unlike cold bending, thermoforming minimizes internal stress and prevents cracking, ensuring durability and dimensional stability in the final product.

Overview of Cold Bending Polycarbonate

Cold bending polycarbonate involves shaping sheets at room temperature without heat, preserving the material's inherent strength and clarity. This method relies on precise mechanical force to achieve gentle curves, ideal for architectural applications requiring minimal distortion and high impact resistance. Unlike thermoforming, cold bending reduces energy consumption and production time, making it a cost-effective choice for flexible design solutions.

Material Properties Affecting Forming Choices

Polycarbonate's high impact resistance and thermal stability make it ideal for thermoforming, allowing precise shaping at elevated temperatures without cracking. Cold bending relies on the material's inherent flexibility and stress resistance but is limited by polycarbonate's tendency to develop stress marks and potential for creep over time. Choosing between thermoforming and cold bending depends on the desired durability, shape complexity, and production volume, with thermoforming preferred for intricate forms and cold bending for simpler, cost-effective applications.

Equipment and Setup Requirements

Thermoforming polycarbonate requires specialized heating equipment such as heated platens or ovens to evenly soften the material, along with vacuum or pressure forming setups to shape the sheets precisely. Cold bending utilizes simpler setups, often involving clamps, jigs, or bending brakes, and relies on the inherent flexibility of polycarbonate without the need for heating elements. Equipment complexity and energy consumption are significantly higher in thermoforming compared to the minimal mechanical tools necessary for cold bending.

Speed and Efficiency: Thermoforming vs Cold Bending

Thermoforming polycarbonate offers faster processing speeds by heating the material to a pliable state, enabling rapid shaping and cooling cycles ideal for high-volume production. Cold bending relies on the polycarbonate's natural flexibility without heat, resulting in slower adjustments and limited precision, reducing overall efficiency for complex forms. Manufacturers prioritize thermoforming for its superior throughput and consistent quality in applications demanding quick turnaround times.

Precision and Design Flexibility Comparison

Thermoforming polycarbonate offers superior precision, enabling complex shapes with tight tolerances and intricate details that cold bending cannot achieve. Cold bending provides greater design flexibility for large, simple curves but lacks the fine control required for detailed architectural or automotive components. Selecting thermoforming ensures enhanced repeatability and consistency in high-precision applications, while cold bending supports cost-effective prototyping and flexible adjustments.

Impact on Polycarbonate Structural Integrity

Thermoforming polycarbonate involves heating the material to a pliable state, allowing it to be shaped without causing micro-cracks, thereby preserving its structural integrity and maintaining high impact resistance. Cold bending, by contrast, applies mechanical stress at ambient temperature, which can induce stress concentrations and weaken the polycarbonate's impact strength over time. Choosing thermoforming over cold bending is essential for applications demanding optimal durability and safety in polycarbonate structures.

Cost Analysis of Both Forming Techniques

Thermoforming polycarbonate involves heating the material to a pliable temperature, allowing complex shapes at moderate tooling costs and faster cycle times, which is cost-effective for large production runs. Cold bending, while requiring minimal energy input and no heating equipment, often leads to higher labor costs and potential material stress, limiting its efficiency for complex or high-volume projects. The cost analysis favors thermoforming for scalability and precision, whereas cold bending suits simple shapes and low-volume or prototype applications with minimal upfront investment.

Best Applications for Thermoforming vs Cold Bending

Thermoforming polycarbonate is ideal for producing complex shapes with uniform thickness, making it suitable for automotive parts, protective shields, and consumer product housings. Cold bending is best applied for simple, curved designs such as architectural glazing and display cases where maintaining optical clarity and material strength without heat distortion is critical. Choosing thermoforming or cold bending depends on the required design complexity, production volume, and mechanical performance of the polycarbonate component.

Thermoforming vs Cold Bending Infographic

materialdif.com

materialdif.com