Optical grade polycarbonate offers superior clarity and light transmission compared to general purpose polycarbonate, making it ideal for lenses and optical components. It features enhanced UV resistance and low haze, ensuring long-lasting transparency in demanding applications. General purpose polycarbonate provides good impact resistance and durability but lacks the refined optical properties required for precision visual performance.

Table of Comparison

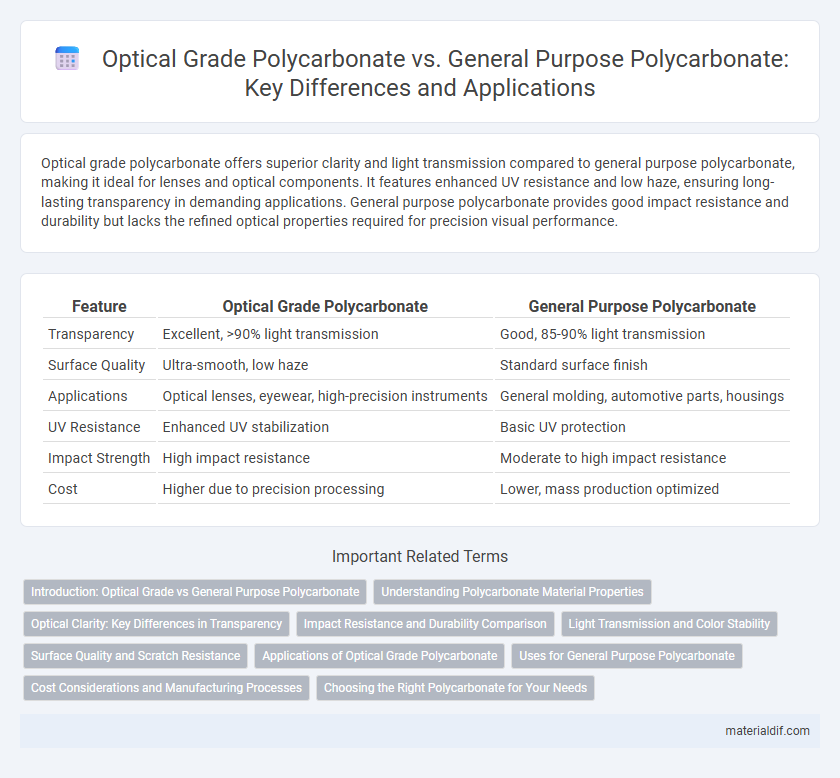

| Feature | Optical Grade Polycarbonate | General Purpose Polycarbonate |

|---|---|---|

| Transparency | Excellent, >90% light transmission | Good, 85-90% light transmission |

| Surface Quality | Ultra-smooth, low haze | Standard surface finish |

| Applications | Optical lenses, eyewear, high-precision instruments | General molding, automotive parts, housings |

| UV Resistance | Enhanced UV stabilization | Basic UV protection |

| Impact Strength | High impact resistance | Moderate to high impact resistance |

| Cost | Higher due to precision processing | Lower, mass production optimized |

Introduction: Optical Grade vs General Purpose Polycarbonate

Optical grade polycarbonate offers superior clarity and light transmission with a typical haze level below 1%, making it ideal for lenses, optical discs, and display screens. General purpose polycarbonate provides robust impact resistance and thermal stability but exhibits higher opacity and haze, which limits its use in optical applications. Differences in polymer purity and processing techniques contribute to the enhanced optical clarity found in optical grade polycarbonate compared to general purpose variants.

Understanding Polycarbonate Material Properties

Optical grade polycarbonate offers superior light transmission up to 89% compared to general purpose polycarbonate, which typically transmits around 85%, making it ideal for applications requiring clarity and precision. Its refractive index of approximately 1.58 contributes to excellent optical performance, while general purpose polycarbonate prioritizes impact resistance and thermal stability with a heat deflection temperature near 135degC. Both materials exhibit high tensile strength around 60 MPa, but optical grade variants ensure minimal birefringence, essential for lenses, displays, and optical components.

Optical Clarity: Key Differences in Transparency

Optical grade polycarbonate exhibits superior transparency with light transmittance rates exceeding 90%, making it ideal for lenses, optical discs, and eyewear applications. General purpose polycarbonate typically has lower optical clarity due to the presence of additives and colorants that reduce transparency and cause slight haze. The difference in purity and manufacturing processes directly impacts the optical quality, with optical grade polycarbonate engineered to minimize light distortion and maximize clarity.

Impact Resistance and Durability Comparison

Optical grade polycarbonate offers superior impact resistance compared to general purpose polycarbonate, making it ideal for applications requiring high durability and clarity, such as eyewear lenses and optical discs. Its advanced manufacturing process enhances toughness, reducing the risk of cracks and fractures under stress, which outperforms the more standard durability levels of general purpose polycarbonate used in everyday products. The increased impact resistance and long-term performance of optical grade polycarbonate also contribute to its higher cost, reflecting its specialized engineering and enhanced material properties.

Light Transmission and Color Stability

Optical grade polycarbonate offers superior light transmission, typically above 90%, ensuring exceptional clarity for lenses and optical components compared to general purpose polycarbonate, which has lower and less consistent transparency. It also exhibits enhanced color stability due to specialized UV stabilizers and additives, preventing yellowing and maintaining optical performance over prolonged exposure to sunlight. These properties make optical grade polycarbonate the preferred choice in precision applications requiring long-term visual clarity and durability.

Surface Quality and Scratch Resistance

Optical grade polycarbonate offers superior surface quality characterized by high clarity and minimal defects, making it ideal for lenses and optical applications. Its enhanced scratch resistance is achieved through specialized coatings, significantly outperforming general purpose polycarbonate, which typically has a rougher surface and lower abrasion resistance. These attributes ensure optical grade polycarbonate maintains visual integrity and durability in demanding environments.

Applications of Optical Grade Polycarbonate

Optical grade polycarbonate is engineered for high transparency and minimal light distortion, making it ideal for applications such as eyewear lenses, automotive headlamp covers, and optical discs. Its superior clarity and UV resistance enable precise light transmission in medical devices and display screens. Compared to general purpose polycarbonate, optical grade material supports more demanding optical performance requirements in advanced technology fields.

Uses for General Purpose Polycarbonate

General Purpose Polycarbonate is widely used in electronics housings, automotive components, and construction materials due to its excellent impact resistance and thermal stability. This type of polycarbonate is preferred for applications requiring durability and cost-efficiency rather than optical clarity. It also serves in electrical insulation parts and protective gear where high mechanical strength is essential.

Cost Considerations and Manufacturing Processes

Optical grade polycarbonate offers superior clarity and light transmission compared to general purpose polycarbonate, but it requires more precise and controlled manufacturing processes, leading to higher production costs. The enhanced purity and specialized additives in optical grade polycarbonate increase raw material expenses and processing time, affecting overall cost efficiency. In contrast, general purpose polycarbonate is manufactured using standard molding techniques with fewer quality controls, making it a more cost-effective choice for applications where optical performance is not critical.

Choosing the Right Polycarbonate for Your Needs

Optical grade polycarbonate offers superior clarity, light transmission up to 90%, and low birefringence, making it ideal for lenses, optical discs, and medical devices requiring precise optical performance. General purpose polycarbonate provides excellent impact resistance and durability at a lower cost, suitable for automotive parts, enclosures, and consumer products where optical clarity is not critical. Selecting the right polycarbonate depends on application-specific requirements like optical properties, mechanical strength, and budget constraints to ensure optimal performance and value.

Optical Grade Polycarbonate vs General Purpose Polycarbonate Infographic

materialdif.com

materialdif.com