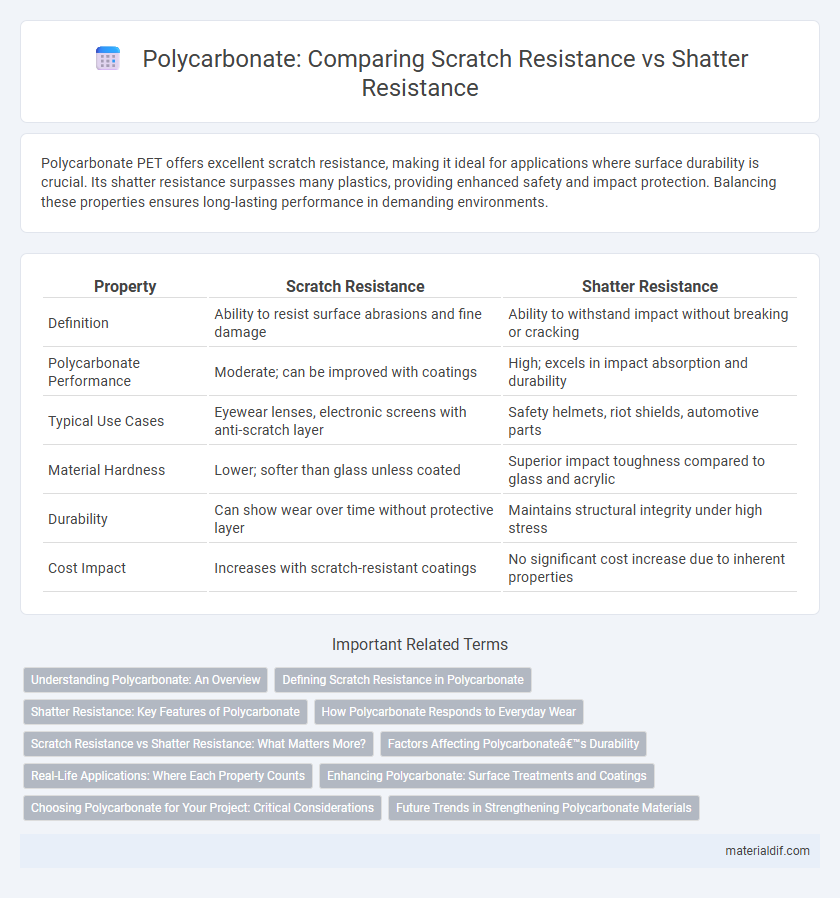

Polycarbonate PET offers excellent scratch resistance, making it ideal for applications where surface durability is crucial. Its shatter resistance surpasses many plastics, providing enhanced safety and impact protection. Balancing these properties ensures long-lasting performance in demanding environments.

Table of Comparison

| Property | Scratch Resistance | Shatter Resistance |

|---|---|---|

| Definition | Ability to resist surface abrasions and fine damage | Ability to withstand impact without breaking or cracking |

| Polycarbonate Performance | Moderate; can be improved with coatings | High; excels in impact absorption and durability |

| Typical Use Cases | Eyewear lenses, electronic screens with anti-scratch layer | Safety helmets, riot shields, automotive parts |

| Material Hardness | Lower; softer than glass unless coated | Superior impact toughness compared to glass and acrylic |

| Durability | Can show wear over time without protective layer | Maintains structural integrity under high stress |

| Cost Impact | Increases with scratch-resistant coatings | No significant cost increase due to inherent properties |

Understanding Polycarbonate: An Overview

Polycarbonate combines exceptional shatter resistance with moderate scratch resistance, making it ideal for impact-prone applications like safety glasses and protective gear. Its molecular structure provides high impact strength, preventing cracks and breaks, while surface treatments or coatings are necessary to enhance its scratch resistance. Understanding these properties helps optimize polycarbonate use in environments where durability and clarity are crucial.

Defining Scratch Resistance in Polycarbonate

Scratch resistance in polycarbonate refers to the material's ability to withstand surface abrasions that can cause visible marks or dullness, preserving its clarity and aesthetic appeal. This property is crucial for applications such as eyewear lenses, protective visors, and automotive parts, where maintaining optical clarity is essential. While polycarbonate is naturally impact-resistant, specialized scratch-resistant coatings or treatments are often applied to enhance its surface durability without compromising shatter resistance.

Shatter Resistance: Key Features of Polycarbonate

Polycarbonate exhibits exceptional shatter resistance, making it a preferred material for safety applications such as bulletproof windows and protective eyewear. Its molecular structure allows it to absorb and disperse impact energy without cracking or breaking, providing superior durability compared to glass or acrylic. This impact strength enhances safety and longevity in automotive, construction, and electronic device components.

How Polycarbonate Responds to Everyday Wear

Polycarbonate exhibits excellent shatter resistance, making it highly durable against impacts and preventing breakage in everyday use. However, it tends to be more susceptible to scratches compared to tougher materials like tempered glass, which can affect its clarity over time. Protective coatings are often applied to polycarbonate surfaces to enhance scratch resistance and maintain visual quality during daily wear.

Scratch Resistance vs Shatter Resistance: What Matters More?

Scratch resistance in polycarbonate enhances surface durability, preventing visible wear and maintaining optical clarity, essential for applications like eyewear and protective screens. Shatter resistance ensures structural integrity under impact, crucial for safety gear, automotive components, and security windows. Balancing both properties depends on the end use, but shatter resistance often takes precedence in safety-critical environments where impact protection is paramount.

Factors Affecting Polycarbonate’s Durability

Polycarbonate's durability is influenced by factors such as material thickness, surface coating, and environmental exposure. Enhanced scratch resistance is typically achieved through hard coatings that increase surface hardness without compromising shatter resistance, which depends on the intrinsic toughness of the polymer matrix. UV radiation, temperature fluctuations, and chemical contact also affect polycarbonate's ability to resist both scratches and impact shattering over time.

Real-Life Applications: Where Each Property Counts

Polycarbonate's scratch resistance is crucial for applications like eyeglass lenses and smartphone screens, where surface clarity and durability against daily wear are paramount. Shatter resistance is essential in safety gear, automotive components, and protective visors, where impact absorption and preventing fragmentation protect users from injury. Selecting polycarbonate with the right balance of scratch and shatter resistance depends on the specific demands of the real-life environment and intended use.

Enhancing Polycarbonate: Surface Treatments and Coatings

Surface treatments and specialized coatings significantly enhance polycarbonate's scratch resistance by adding a protective hard layer without compromising its inherent shatter resistance. Advanced anti-scratch coatings, such as silicon-based or diamond-like carbon (DLC) coatings, create a durable barrier that maintains optical clarity while resisting abrasion. These enhancements preserve polycarbonate's impact strength, ensuring long-lasting performance in applications requiring both toughness and surface durability.

Choosing Polycarbonate for Your Project: Critical Considerations

Polycarbonate offers superior shatter resistance, making it ideal for applications requiring robust impact protection, while its scratch resistance is moderate and may necessitate protective coatings for enhanced durability. When choosing polycarbonate for your project, prioritize its ability to withstand high-impact forces without fracturing, especially in safety-critical environments like automotive or protective gear. Consider the trade-off between durability and surface finish, ensuring treatments like hard coatings are applied if scratch resistance is crucial to maintain optical clarity and aesthetics.

Future Trends in Strengthening Polycarbonate Materials

Future trends in strengthening polycarbonate materials emphasize enhancing both scratch resistance and shatter resistance through nanocomposite technology and advanced surface coatings. Incorporating silica nanoparticles and ionic cross-linkers improves scratch durability while maintaining the inherent impact resistance of polycarbonate. Research in self-healing polymers and hybrid blends promises to deliver next-generation polycarbonates with superior longevity and structural integrity.

Scratch Resistance vs Shatter Resistance Infographic

materialdif.com

materialdif.com