Polycarbonate blends combine the toughness of pure polycarbonate with enhanced properties such as improved chemical resistance, UV stability, or cost-effectiveness, making them versatile for a wider range of applications. Pure polycarbonate offers superior clarity, high impact resistance, and excellent thermal stability, ideal for demanding environments where performance is critical. Choosing between polycarbonate blends and pure polycarbonate depends on specific application requirements including durability, aesthetics, and budget constraints.

Table of Comparison

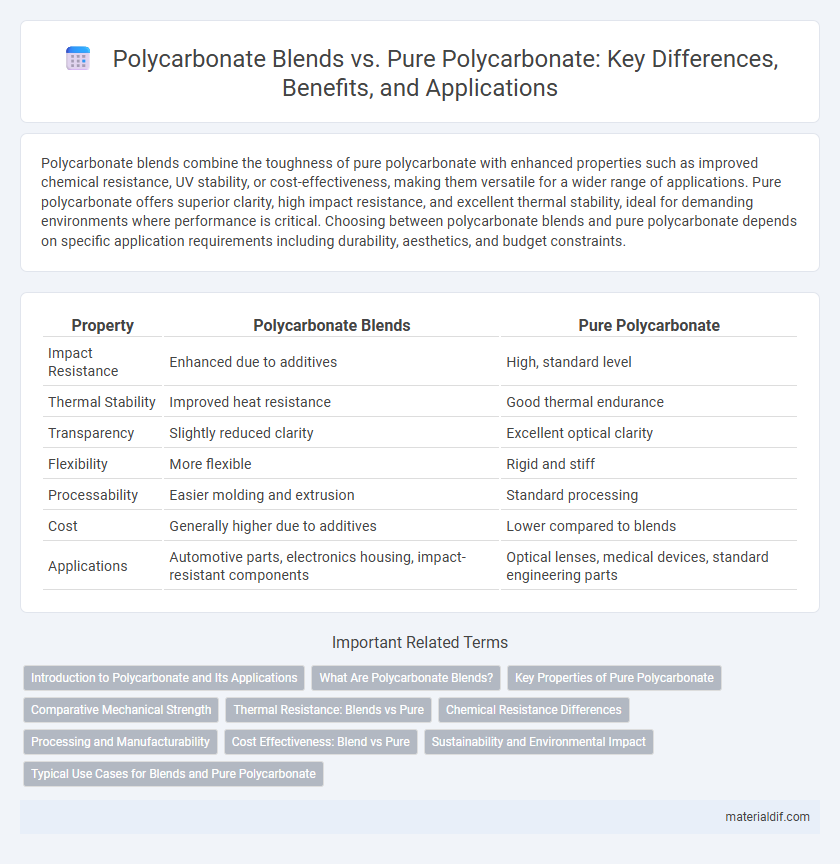

| Property | Polycarbonate Blends | Pure Polycarbonate |

|---|---|---|

| Impact Resistance | Enhanced due to additives | High, standard level |

| Thermal Stability | Improved heat resistance | Good thermal endurance |

| Transparency | Slightly reduced clarity | Excellent optical clarity |

| Flexibility | More flexible | Rigid and stiff |

| Processability | Easier molding and extrusion | Standard processing |

| Cost | Generally higher due to additives | Lower compared to blends |

| Applications | Automotive parts, electronics housing, impact-resistant components | Optical lenses, medical devices, standard engineering parts |

Introduction to Polycarbonate and Its Applications

Polycarbonate blends combine pure polycarbonate with other polymers or additives to enhance performance characteristics such as impact resistance, heat stability, and UV protection, expanding their application range in automotive parts, electronics, and construction. Pure polycarbonate is known for its exceptional clarity, high toughness, and thermal resistance, making it ideal for optical lenses, medical devices, and protective gear. The choice between polycarbonate blends and pure polycarbonate depends on specific application requirements, balancing properties like strength, durability, and cost-effectiveness.

What Are Polycarbonate Blends?

Polycarbonate blends are composite materials created by combining pure polycarbonate with other polymers or additives to enhance specific properties such as impact resistance, heat resistance, or flexibility. These blends offer tailored performance attributes that pure polycarbonate alone may not provide, making them suitable for specialized applications in automotive, electronics, and construction industries. The blending process improves mechanical strength, thermal stability, and chemical resistance, optimizing the material for diverse manufacturing requirements.

Key Properties of Pure Polycarbonate

Pure polycarbonate exhibits exceptional impact resistance, high optical clarity, and excellent dimensional stability, making it ideal for applications requiring durability and transparency. Its high heat resistance and superior electrical insulation properties further enhance its performance in demanding environments. Unlike polycarbonate blends, pure polycarbonate maintains consistent mechanical and thermal characteristics without compromise from additive components.

Comparative Mechanical Strength

Polycarbonate blends often exhibit enhanced mechanical strength compared to pure polycarbonate by combining properties of multiple polymers, resulting in improved impact resistance and flexibility. Pure polycarbonate offers high tensile strength and excellent dimensional stability but may lack the tailored toughness achievable through blending. The choice between pure polycarbonate and blends depends on specific application requirements where factors like impact resistance, stiffness, and durability are critical.

Thermal Resistance: Blends vs Pure

Polycarbonate blends often exhibit enhanced thermal resistance compared to pure polycarbonate due to the incorporation of additives or other polymers that improve heat deflection temperature and reduce thermal deformation. Pure polycarbonate typically has a heat deflection temperature around 135degC, while blends can achieve higher thresholds, sometimes exceeding 150degC depending on the specific blend composition. This increased thermal stability in blends makes them more suitable for applications requiring prolonged exposure to elevated temperatures or thermal cycling.

Chemical Resistance Differences

Polycarbonate blends often incorporate additives or other polymers that can alter the chemical resistance compared to pure polycarbonate, which is known for its robust resistance to many acids and alcohols but poor tolerance to solvents like ketones and aromatic hydrocarbons. Pure polycarbonate typically maintains structural integrity when exposed to dilute alkalis and most aqueous solutions, whereas blends may exhibit enhanced or reduced resistance depending on the specific components mixed. Understanding the specific chemical environment and blend formulation is crucial for selecting the appropriate polycarbonate material for applications requiring targeted chemical resistance.

Processing and Manufacturability

Polycarbonate blends offer enhanced processing flexibility compared to pure polycarbonate by improving melt flow characteristics and reducing cycle times, which enables faster injection molding and extrusion. Pure polycarbonate provides superior optical clarity and impact resistance but can be more challenging to process due to higher melt viscosity and sensitivity to thermal degradation. Manufacturers often select blends to optimize manufacturability while maintaining acceptable mechanical and thermal properties for diverse applications.

Cost Effectiveness: Blend vs Pure

Polycarbonate blends offer enhanced cost effectiveness compared to pure polycarbonate by combining raw materials that reduce overall production expenses while maintaining desirable mechanical properties. Blended polycarbonates often incorporate additives or other polymers to improve impact resistance and processability, enabling manufacturers to achieve specific application requirements at a lower cost. Pure polycarbonate, despite excellent clarity and strength, typically incurs higher material and production costs, making blends a preferred choice for budget-conscious applications without compromising performance.

Sustainability and Environmental Impact

Polycarbonate blends often incorporate recycled materials or biodegradable additives, enhancing sustainability compared to pure polycarbonate, which relies solely on petroleum-based polymers. Blended polycarbonates typically exhibit improved recyclability and reduced carbon footprints, aligning better with circular economy principles. However, the environmental impact varies based on the blend composition and end-of-life processing technologies, making material choice critical for eco-conscious applications.

Typical Use Cases for Blends and Pure Polycarbonate

Polycarbonate blends are commonly used in automotive parts, electronic housings, and medical devices where enhanced chemical resistance and improved impact strength are critical. Pure polycarbonate is preferred in optical lenses, bulletproof glass, and food containers for its superior clarity, excellent toughness, and high heat resistance. Selecting between blends and pure polycarbonate depends on specific application requirements such as durability, transparency, and environmental exposure.

Polycarbonate Blends vs Pure Polycarbonate Infographic

materialdif.com

materialdif.com