High heat polycarbonate offers superior thermal resistance compared to standard polycarbonate, making it ideal for applications involving elevated temperatures. This enhanced heat tolerance allows high heat polycarbonate to maintain its structural integrity and optical clarity under prolonged exposure to heat. Standard polycarbonate, while durable and impact-resistant, may deform or discolor when subjected to higher temperatures.

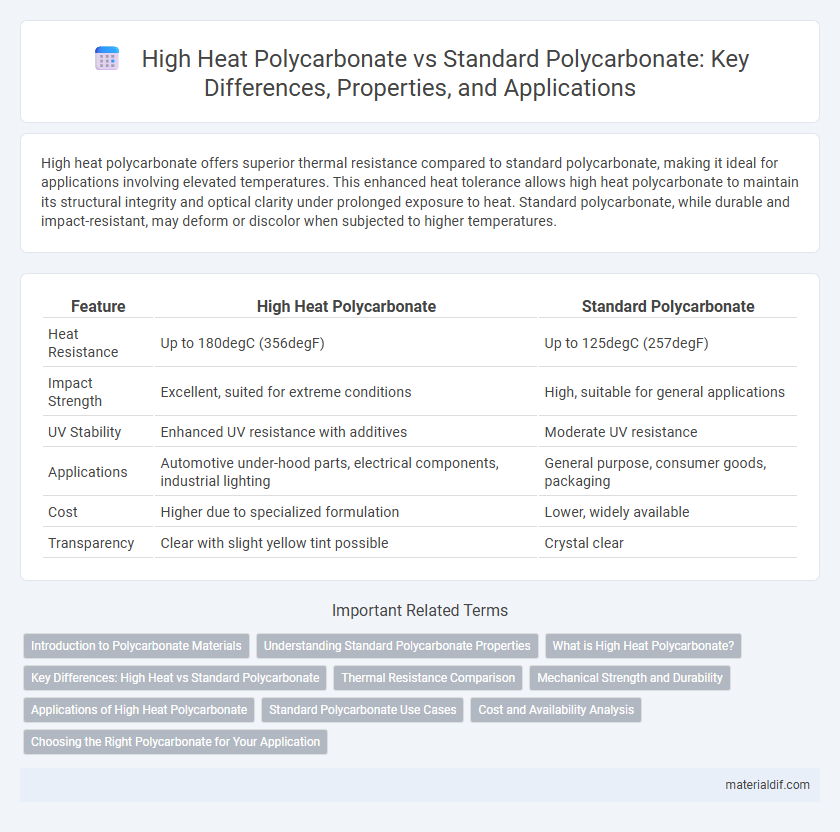

Table of Comparison

| Feature | High Heat Polycarbonate | Standard Polycarbonate |

|---|---|---|

| Heat Resistance | Up to 180degC (356degF) | Up to 125degC (257degF) |

| Impact Strength | Excellent, suited for extreme conditions | High, suitable for general applications |

| UV Stability | Enhanced UV resistance with additives | Moderate UV resistance |

| Applications | Automotive under-hood parts, electrical components, industrial lighting | General purpose, consumer goods, packaging |

| Cost | Higher due to specialized formulation | Lower, widely available |

| Transparency | Clear with slight yellow tint possible | Crystal clear |

Introduction to Polycarbonate Materials

High heat polycarbonate offers enhanced thermal resistance, maintaining structural integrity at temperatures above 135degC, compared to standard polycarbonate, which typically withstands up to 115degC. This improved heat tolerance enables high heat polycarbonate to perform reliably in demanding applications such as automotive components, electrical housings, and industrial equipment. Both materials share excellent impact resistance and optical clarity, but high heat polycarbonate's superior thermal stability broadens its use in environments with elevated temperature requirements.

Understanding Standard Polycarbonate Properties

Standard polycarbonate exhibits high impact resistance, excellent optical clarity, and good dimensional stability, making it suitable for a wide range of applications such as eyewear lenses, automotive parts, and electronic components. It has a typical heat deflection temperature around 130degC, which limits its use in environments subject to prolonged high temperatures. Understanding these properties is essential when comparing with high heat polycarbonate grades that offer enhanced thermal resistance for more demanding industrial applications.

What is High Heat Polycarbonate?

High Heat Polycarbonate is a specially formulated plastic designed to withstand elevated temperatures up to 270degF (132degC) without warping or degrading, making it ideal for applications involving prolonged heat exposure. Unlike standard polycarbonate, which typically tolerates temperatures around 240degF (116degC), high heat variants offer enhanced thermal stability and improved resistance to thermal aging. These properties make High Heat Polycarbonate essential for manufacturing components in automotive, aerospace, and electronics industries where durability under high-temperature conditions is critical.

Key Differences: High Heat vs Standard Polycarbonate

High Heat Polycarbonate offers superior thermal resistance with a heat deflection temperature typically above 135degC, compared to Standard Polycarbonate's lower threshold around 115degC. This enhanced heat tolerance makes High Heat Polycarbonate ideal for applications involving prolonged exposure to elevated temperatures without deformation. Additionally, High Heat Polycarbonate often maintains better optical clarity and mechanical strength at higher temperatures, distinguishing it from standard grades used primarily in general-purpose applications.

Thermal Resistance Comparison

High heat polycarbonate withstands continuous exposure to temperatures up to 135degC (275degF), significantly outperforming standard polycarbonate, which typically endures up to 115degC (239degF). Enhanced thermal resistance in high heat polycarbonate reduces deformation and maintains optical clarity in high-temperature environments. This makes it ideal for applications requiring superior heat stability, such as automotive headlamp lenses and electrical components.

Mechanical Strength and Durability

High Heat Polycarbonate offers superior mechanical strength and enhanced durability compared to Standard Polycarbonate, making it ideal for applications exposed to elevated temperatures. Its improved heat resistance allows it to maintain structural integrity under thermal stress, reducing deformation and prolonging service life. Standard Polycarbonate, while strong, tends to degrade faster and lose mechanical properties when subjected to continuous high-heat environments.

Applications of High Heat Polycarbonate

High Heat Polycarbonate excels in demanding applications requiring superior thermal resistance, such as automotive headlamp lenses, electrical components, and medical devices exposed to sterilization processes. Its enhanced heat distortion temperature allows it to maintain structural integrity and optical clarity under continuous high-temperature exposure, unlike standard polycarbonate. Industries benefiting from these properties often choose High Heat Polycarbonate for manufacturing parts that endure temperatures exceeding 130degC.

Standard Polycarbonate Use Cases

Standard polycarbonate is widely used in manufacturing eyewear lenses, protective gear, and electronic device housings due to its excellent impact resistance and optical clarity. Its versatility makes it ideal for applications requiring high durability combined with transparency, such as in safety glasses, automotive headlamp lenses, and smartphone screens. While it has a lower heat resistance compared to high heat polycarbonate, standard polycarbonate remains preferred for everyday temperature environments and cost-effective production.

Cost and Availability Analysis

High heat polycarbonate typically costs 20-30% more than standard polycarbonate due to enhanced thermal resistance properties suitable for applications exceeding 125degC. Availability of high heat variants is more limited, with fewer suppliers and longer lead times compared to widely produced standard polycarbonate grades. Evaluating project budgets and delivery schedules is critical when choosing between high heat and standard polycarbonate materials.

Choosing the Right Polycarbonate for Your Application

High Heat Polycarbonate withstands continuous use temperatures up to 270degF, making it ideal for industrial applications involving elevated heat exposure, while Standard Polycarbonate is suitable for general-purpose use with temperature resistance up to 230degF. Selecting the right polycarbonate depends on specific application requirements such as thermal stability, impact strength, and UV resistance. For demanding environments, High Heat Polycarbonate ensures durability and maintains mechanical properties, whereas Standard Polycarbonate offers cost-effective performance for less heat-intensive conditions.

High Heat Polycarbonate vs Standard Polycarbonate Infographic

materialdif.com

materialdif.com