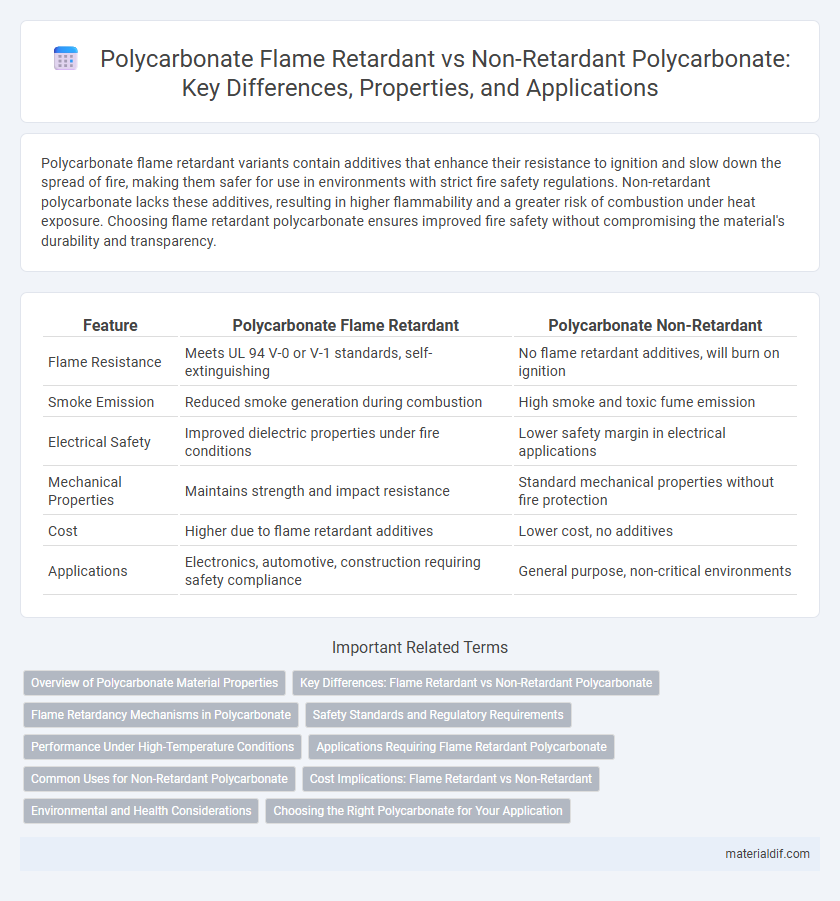

Polycarbonate flame retardant variants contain additives that enhance their resistance to ignition and slow down the spread of fire, making them safer for use in environments with strict fire safety regulations. Non-retardant polycarbonate lacks these additives, resulting in higher flammability and a greater risk of combustion under heat exposure. Choosing flame retardant polycarbonate ensures improved fire safety without compromising the material's durability and transparency.

Table of Comparison

| Feature | Polycarbonate Flame Retardant | Polycarbonate Non-Retardant |

|---|---|---|

| Flame Resistance | Meets UL 94 V-0 or V-1 standards, self-extinguishing | No flame retardant additives, will burn on ignition |

| Smoke Emission | Reduced smoke generation during combustion | High smoke and toxic fume emission |

| Electrical Safety | Improved dielectric properties under fire conditions | Lower safety margin in electrical applications |

| Mechanical Properties | Maintains strength and impact resistance | Standard mechanical properties without fire protection |

| Cost | Higher due to flame retardant additives | Lower cost, no additives |

| Applications | Electronics, automotive, construction requiring safety compliance | General purpose, non-critical environments |

Overview of Polycarbonate Material Properties

Polycarbonate flame retardant variants exhibit enhanced thermal stability and reduced flammability, meeting UL 94 V-0 or V-1 fire safety standards, which is critical for applications in electronics and construction. Non-retardant polycarbonate offers high impact resistance, optical clarity, and dimensional stability but lacks specialized additives, making it more susceptible to ignition and fire propagation. Both types maintain excellent mechanical strength and transparency, but flame retardant grades incorporate halogen-free or brominated compounds to suppress combustion and improve safety performance.

Key Differences: Flame Retardant vs Non-Retardant Polycarbonate

Flame retardant polycarbonate incorporates specialized additives that significantly enhance its resistance to ignition and slow down combustion, making it suitable for applications requiring strict fire safety standards. In contrast, non-retardant polycarbonate lacks these flame inhibiting chemicals, resulting in a higher flammability rating and limited use in environments where fire hazards exist. The key differences include factors such as UL 94 V-0 rating compliance, smoke emission levels, and thermal stability during exposure to high temperatures.

Flame Retardancy Mechanisms in Polycarbonate

Polycarbonate flame retardancy is primarily achieved through the incorporation of flame retardant additives such as brominated compounds, phosphorus-based agents, or intumescent systems that promote char formation and inhibit flame propagation. These mechanisms function by disrupting the radical chain reactions in combustion or forming protective char layers, effectively reducing heat release and smoke production compared to non-retardant polycarbonate. Non-retardant polycarbonate lacks these additives, making it more susceptible to ignition, rapid flame spread, and sustained burning under high-temperature conditions.

Safety Standards and Regulatory Requirements

Polycarbonate flame retardant grades comply with strict safety standards such as UL 94 V-0, ensuring enhanced fire resistance for applications in electronics and construction, whereas non-retardant polycarbonate generally meets basic safety requirements but lacks high-level fire protection. Regulatory requirements like REACH and RoHS emphasize the necessity of flame retardant additives in polycarbonate materials used in consumer products to minimize fire hazards. Choosing flame retardant polycarbonate significantly reduces the risk of ignition and toxic smoke emission, meeting critical standards for fire safety in industrial and consumer applications.

Performance Under High-Temperature Conditions

Polycarbonate flame retardant grades exhibit superior thermal stability, maintaining structural integrity and flame resistance at temperatures up to 150degC, compared to non-retardant polycarbonate which softens and deforms above 130degC. Flame retardant polycarbonate formulations include additives such as brominated compounds and phosphorus-based stabilizers, enhancing their performance under high-temperature conditions and preventing combustion. Non-retardant polycarbonate lacks these additives, resulting in lower heat resistance and increased risk of ignition and material failure when exposed to elevated temperatures.

Applications Requiring Flame Retardant Polycarbonate

Polycarbonate flame retardant grades are essential for applications in electrical housings, automotive components, and building materials where stringent fire safety standards must be met. These flame retardant polycarbonates limit the spread of flames and reduce smoke production, enhancing overall safety in environments prone to fire hazards. Non-retardant polycarbonate, while offering excellent impact resistance and transparency, lacks the necessary fire resistance for use in regulated safety-critical applications.

Common Uses for Non-Retardant Polycarbonate

Non-retardant polycarbonate is widely utilized in applications where high impact resistance and optical clarity are essential, such as eyewear lenses, automotive headlamp covers, and electronic display screens. Its non-flame-retardant nature makes it suitable for environments with low fire risk, enabling superior transparency and durability without added chemical modifiers. Common uses also include glazing materials and protective covers, where aesthetic appeal and mechanical strength are prioritized over flame resistance.

Cost Implications: Flame Retardant vs Non-Retardant

Flame retardant polycarbonate typically incurs higher production costs due to the incorporation of specialized additives that enhance fire resistance, resulting in a price increase of 15-30% compared to non-retardant variants. Non-retardant polycarbonate offers a more budget-friendly option but lacks the enhanced safety features required for applications with strict fire safety regulations. Choosing between flame retardant and non-retardant polycarbonate involves balancing upfront material expenses against long-term compliance and safety benefits.

Environmental and Health Considerations

Polycarbonate flame retardant variants often incorporate brominated or phosphorus-based additives that can release toxic substances like dioxins or phosphates during combustion, posing environmental and health risks. Non-retardant polycarbonate lacks these additives, resulting in cleaner combustion but increased flammability, which may necessitate stricter fire safety measures. Evaluating the trade-offs between flame retardancy and chemical safety is critical for minimizing ecological impact and human exposure to harmful compounds.

Choosing the Right Polycarbonate for Your Application

Polycarbonate flame retardant grades offer enhanced fire resistance, meeting UL 94 V-0 standards, making them ideal for electrical enclosures and construction applications where safety is critical. Non-retardant polycarbonate provides superior optical clarity and impact resistance, suitable for lenses, glazing, and automotive parts where flame retardancy is not mandatory. Selecting the right polycarbonate depends on balancing fire safety requirements with mechanical properties to ensure optimal performance and compliance.

Polycarbonate Flame Retardancy vs Polycarbonate Non-retardant Infographic

materialdif.com

materialdif.com