Polycarbonate twinwall sheets offer superior thermal insulation and lightweight properties due to their multi-wall structure, making them ideal for applications requiring energy efficiency and impact resistance. In contrast, polycarbonate solid sheets provide higher strength, greater durability, and excellent optical clarity, suitable for demanding applications where rigidity and transparency are critical. Choosing between the two depends on specific project needs such as insulation versus strength and weight considerations.

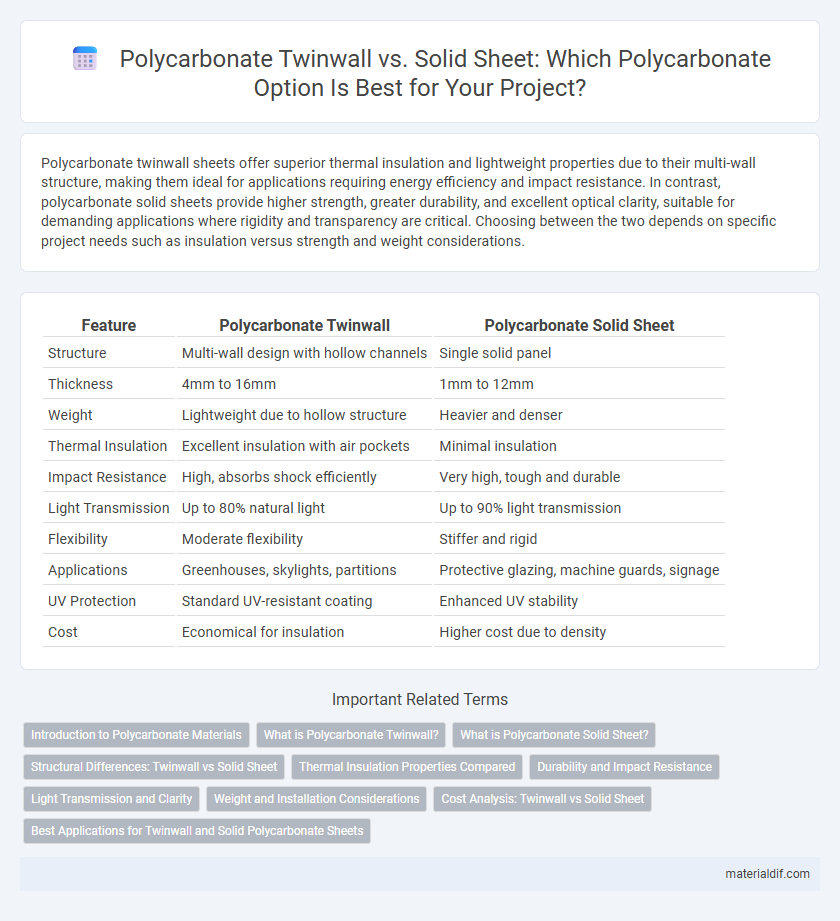

Table of Comparison

| Feature | Polycarbonate Twinwall | Polycarbonate Solid Sheet |

|---|---|---|

| Structure | Multi-wall design with hollow channels | Single solid panel |

| Thickness | 4mm to 16mm | 1mm to 12mm |

| Weight | Lightweight due to hollow structure | Heavier and denser |

| Thermal Insulation | Excellent insulation with air pockets | Minimal insulation |

| Impact Resistance | High, absorbs shock efficiently | Very high, tough and durable |

| Light Transmission | Up to 80% natural light | Up to 90% light transmission |

| Flexibility | Moderate flexibility | Stiffer and rigid |

| Applications | Greenhouses, skylights, partitions | Protective glazing, machine guards, signage |

| UV Protection | Standard UV-resistant coating | Enhanced UV stability |

| Cost | Economical for insulation | Higher cost due to density |

Introduction to Polycarbonate Materials

Polycarbonate twinwall sheets feature a cellular core design that provides excellent thermal insulation and impact resistance, making them ideal for roofing and glazing applications. In contrast, polycarbonate solid sheets offer superior clarity, strength, and weather resistance, commonly used where transparency and durability are required. Both materials exhibit high UV resistance and lightweight properties, but their structural differences determine suitability for specific construction and industrial uses.

What is Polycarbonate Twinwall?

Polycarbonate twinwall is a lightweight, multiwall sheet featuring two layers separated by vertical ribs, providing enhanced insulation and impact resistance compared to solid polycarbonate sheets. This structure increases thermal efficiency, reduces weight, and maintains durability, making twinwall polycarbonate ideal for greenhouse panels, roofing, and cladding applications. Unlike solid polycarbonate sheets that offer maximum strength and clarity, twinwall variants prioritize energy efficiency and cost-effectiveness without sacrificing structural integrity.

What is Polycarbonate Solid Sheet?

Polycarbonate Solid Sheet is a highly durable, transparent thermoplastic known for its exceptional impact resistance and clarity, making it ideal for applications requiring strong, clear panels such as glazing, machine guards, and safety windows. Unlike polycarbonate twinwall sheets, which feature a hollow structure for lightweight thermal insulation, solid sheets provide superior strength and rigidity due to their dense, non-layered composition. These sheets also exhibit excellent UV resistance and dimensional stability, ensuring long-lasting performance in both indoor and outdoor environments.

Structural Differences: Twinwall vs Solid Sheet

Polycarbonate twinwall sheets feature a multi-wall structure with internal ribs creating air pockets that provide enhanced insulation and lightweight strength. In contrast, polycarbonate solid sheets are a single, dense layer offering superior impact resistance and clarity but less thermal insulation. The twinwall design optimizes structural flexibility and thermal performance, while solid sheets prioritize durability and optical clarity for demanding applications.

Thermal Insulation Properties Compared

Polycarbonate twinwall sheets offer superior thermal insulation compared to polycarbonate solid sheets due to their multi-wall structure that traps air between layers, reducing heat transfer. The R-value of twinwall polycarbonate can be up to three times higher than that of solid sheets, making them ideal for energy-efficient glazing and greenhouse applications. Solid polycarbonate sheets, while providing excellent impact resistance and clarity, have lower insulating properties, making them less effective for temperature regulation.

Durability and Impact Resistance

Polycarbonate twinwall sheets offer enhanced impact resistance due to their multi-layered structure, which absorbs shocks and reduces the risk of cracking. Solid polycarbonate sheets provide superior durability, with greater thickness and density contributing to increased strength and long-term performance in harsh environments. Both materials exhibit exceptional resistance to impact, but solid sheets are typically preferred for applications requiring maximum toughness and structural integrity.

Light Transmission and Clarity

Polycarbonate solid sheets offer superior light transmission and exceptional optical clarity, making them ideal for applications requiring maximum transparency. Twinwall polycarbonate sheets provide reduced light transmission due to their multi-wall structure, which enhances insulation but slightly diffuses clarity. Choosing between the two depends on balancing the need for clear visibility and enhanced thermal performance.

Weight and Installation Considerations

Polycarbonate twinwall sheets are significantly lighter than solid polycarbonate sheets, making them easier to handle and install, especially in large-scale projects where weight reduction is crucial. The hollow twinwall structure not only reduces weight but also improves thermal insulation, enhancing energy efficiency while requiring less robust supporting frameworks during installation. Solid polycarbonate sheets, being denser and heavier, offer greater impact resistance but demand more labor and stronger support systems, impacting overall installation time and complexity.

Cost Analysis: Twinwall vs Solid Sheet

Polycarbonate twinwall sheets typically cost 20-30% less than solid polycarbonate sheets due to their hollow structure, which uses less raw material while maintaining strength and durability. The twinwall design offers superior insulation properties, reducing energy costs in building applications compared to solid sheets. Despite the lower initial cost, solid polycarbonate sheets provide higher impact resistance and clarity, which may justify the premium price for specific applications.

Best Applications for Twinwall and Solid Polycarbonate Sheets

Polycarbonate twinwall sheets are best suited for applications requiring excellent insulation, lightweight structure, and durability, such as greenhouses, skylights, and roofing panels. Solid polycarbonate sheets excel in impact resistance and optical clarity, making them ideal for security glazing, machine guards, and bullet-resistant windows. Both materials offer UV protection but differ in thermal insulation and strength, guiding their use based on specific project requirements.

Polycarbonate Twinwall vs Polycarbonate Solid Sheet Infographic

materialdif.com

materialdif.com