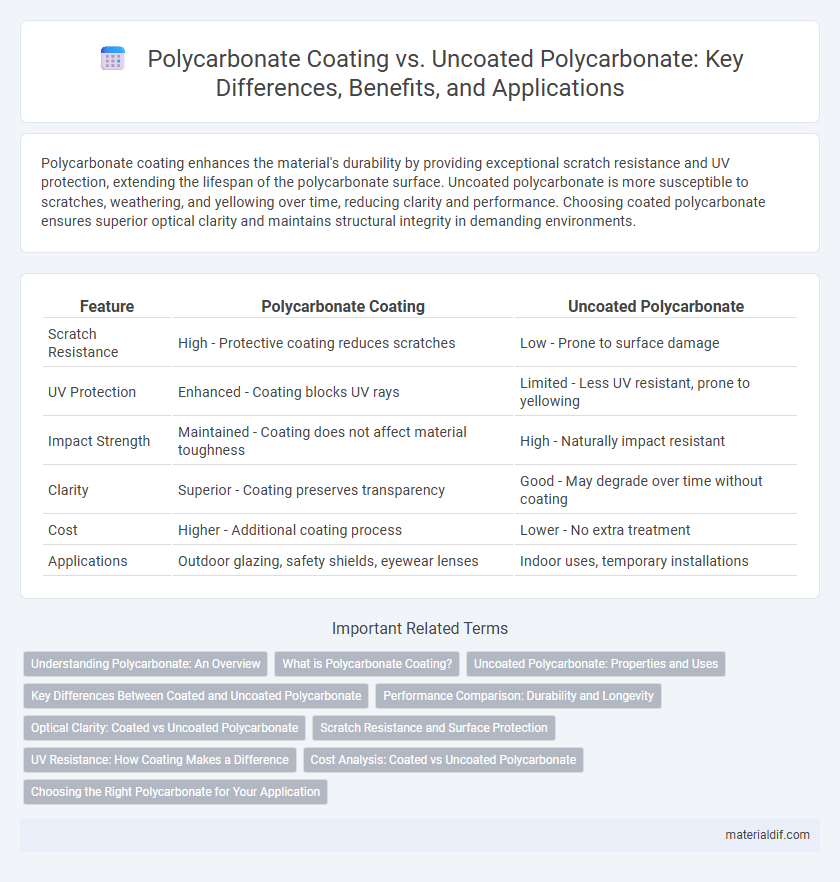

Polycarbonate coating enhances the material's durability by providing exceptional scratch resistance and UV protection, extending the lifespan of the polycarbonate surface. Uncoated polycarbonate is more susceptible to scratches, weathering, and yellowing over time, reducing clarity and performance. Choosing coated polycarbonate ensures superior optical clarity and maintains structural integrity in demanding environments.

Table of Comparison

| Feature | Polycarbonate Coating | Uncoated Polycarbonate |

|---|---|---|

| Scratch Resistance | High - Protective coating reduces scratches | Low - Prone to surface damage |

| UV Protection | Enhanced - Coating blocks UV rays | Limited - Less UV resistant, prone to yellowing |

| Impact Strength | Maintained - Coating does not affect material toughness | High - Naturally impact resistant |

| Clarity | Superior - Coating preserves transparency | Good - May degrade over time without coating |

| Cost | Higher - Additional coating process | Lower - No extra treatment |

| Applications | Outdoor glazing, safety shields, eyewear lenses | Indoor uses, temporary installations |

Understanding Polycarbonate: An Overview

Polycarbonate coating enhances durability by providing increased scratch resistance and UV protection compared to uncoated polycarbonate, which is more prone to surface damage and yellowing over time. Uncoated polycarbonate offers higher clarity and cost-effectiveness but requires more frequent maintenance to preserve its optical properties. Understanding these differences is crucial for selecting the appropriate polycarbonate type for applications such as eyewear lenses, automotive parts, and construction materials.

What is Polycarbonate Coating?

Polycarbonate coating is a specialized layer applied to polycarbonate sheets to enhance surface durability, UV resistance, and scratch protection. This coating significantly prolongs the lifespan of polycarbonate materials by preventing yellowing and damage caused by exposure to sunlight and abrasive elements. Uncoated polycarbonate lacks these protective features, making it more vulnerable to weathering and mechanical wear.

Uncoated Polycarbonate: Properties and Uses

Uncoated polycarbonate exhibits high impact resistance, exceptional optical clarity, and strong UV resistance, making it ideal for applications requiring durability and transparency without additional surface treatments. Its inherent thermal stability and lightweight nature allow widespread use in automotive components, eyewear lenses, and protective barriers. However, uncoated polycarbonate is more prone to surface scratches and chemical exposure compared to coated variants, influencing its suitability in harsh environments.

Key Differences Between Coated and Uncoated Polycarbonate

Polycarbonate coating significantly enhances the material's scratch resistance, UV protection, and chemical durability, compared to uncoated polycarbonate which is more prone to surface damage and yellowing over time. Coated polycarbonate maintains optical clarity and structural integrity in harsh environments, while uncoated variants may degrade faster under UV exposure and abrasion. The added protective layer increases lifespan and performance, making coated polycarbonate suitable for applications demanding long-term reliability and high durability.

Performance Comparison: Durability and Longevity

Polycarbonate coating significantly enhances durability by providing superior resistance to scratches, UV radiation, and chemical exposure compared to uncoated polycarbonate, which is prone to surface wear and yellowing over time. Coated polycarbonate exhibits extended longevity, maintaining optical clarity and mechanical strength for over 10 years under harsh environmental conditions, while uncoated variants degrade faster, often requiring replacement within 5 years. This performance difference makes coated polycarbonate the preferred choice in applications demanding long-term reliability and minimal maintenance.

Optical Clarity: Coated vs Uncoated Polycarbonate

Polycarbonate coating significantly enhances optical clarity by reducing surface reflections and preventing scratches, maintaining transparency over time. Uncoated polycarbonate, while naturally clear, is more prone to surface abrasions and UV damage, which can lead to haze and diminished visibility. Coated surfaces preserve the polycarbonate's inherent clarity, making them ideal for applications requiring long-lasting optical performance.

Scratch Resistance and Surface Protection

Polycarbonate coating significantly enhances scratch resistance by providing a durable protective layer that preserves the material's clarity and structural integrity. Uncoated polycarbonate is more susceptible to abrasion and surface damage, which can lead to premature wear and reduced optical performance. The coating not only improves surface protection but also extends the lifespan of polycarbonate in high-impact and harsh environmental applications.

UV Resistance: How Coating Makes a Difference

Polycarbonate coating significantly enhances UV resistance by forming a protective barrier that prevents harmful ultraviolet rays from degrading the material's surface. Uncoated polycarbonate often suffers from yellowing, brittleness, and reduced mechanical strength due to prolonged UV exposure. This UV protective coating extends the lifespan and maintains the optical clarity of polycarbonate, making it ideal for outdoor applications such as glazing and eyewear lenses.

Cost Analysis: Coated vs Uncoated Polycarbonate

Polycarbonate coating significantly increases the material's resistance to scratches, UV rays, and chemical degradation, which extends the lifespan and reduces maintenance costs compared to uncoated polycarbonate. Although coated polycarbonate has a higher upfront price, its durability minimizes replacement frequency, resulting in lower long-term expenses. Uncoated polycarbonate offers lower initial costs but may incur higher costs over time due to increased susceptibility to damage and environmental wear.

Choosing the Right Polycarbonate for Your Application

Polycarbonate coating significantly enhances impact resistance, UV protection, and scratch durability compared to uncoated polycarbonate, making it ideal for outdoor and high-wear applications. Uncoated polycarbonate offers greater cost efficiency and maintains excellent optical clarity for indoor or temporary uses where surface damage risk is minimal. Selecting the right polycarbonate depends on balancing durability requirements, exposure conditions, and budget constraints to ensure optimal performance and longevity.

Polycarbonate Coating vs Uncoated Polycarbonate Infographic

materialdif.com

materialdif.com