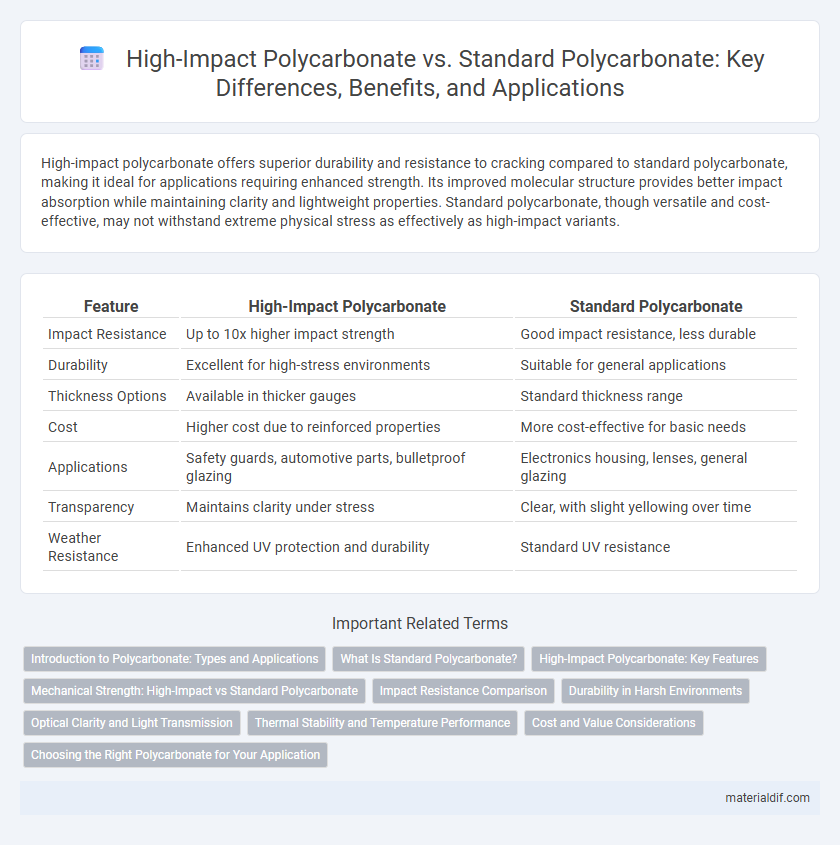

High-impact polycarbonate offers superior durability and resistance to cracking compared to standard polycarbonate, making it ideal for applications requiring enhanced strength. Its improved molecular structure provides better impact absorption while maintaining clarity and lightweight properties. Standard polycarbonate, though versatile and cost-effective, may not withstand extreme physical stress as effectively as high-impact variants.

Table of Comparison

| Feature | High-Impact Polycarbonate | Standard Polycarbonate |

|---|---|---|

| Impact Resistance | Up to 10x higher impact strength | Good impact resistance, less durable |

| Durability | Excellent for high-stress environments | Suitable for general applications |

| Thickness Options | Available in thicker gauges | Standard thickness range |

| Cost | Higher cost due to reinforced properties | More cost-effective for basic needs |

| Applications | Safety guards, automotive parts, bulletproof glazing | Electronics housing, lenses, general glazing |

| Transparency | Maintains clarity under stress | Clear, with slight yellowing over time |

| Weather Resistance | Enhanced UV protection and durability | Standard UV resistance |

Introduction to Polycarbonate: Types and Applications

High-impact polycarbonate offers enhanced toughness and resistance to impact compared to standard polycarbonate, making it ideal for applications requiring durability such as safety helmets, automotive components, and protective gear. Standard polycarbonate provides excellent clarity and heat resistance, commonly used in optical lenses, electronic devices, and architectural glazing. Both types leverage polycarbonate's lightweight, shatterproof properties but differ in performance characteristics suited for specific industrial and consumer uses.

What Is Standard Polycarbonate?

Standard polycarbonate is a versatile thermoplastic polymer known for its clarity, lightweight properties, and moderate impact resistance, commonly used in eyewear lenses, glazing, and electronic components. Its molecular structure provides good optical clarity and heat resistance but offers lower toughness compared to high-impact polycarbonate variants. Standard polycarbonate balances cost-effectiveness with sufficient durability for general-purpose applications where extreme impact resistance is not critical.

High-Impact Polycarbonate: Key Features

High-impact polycarbonate exhibits superior mechanical strength and enhanced impact resistance compared to standard polycarbonate, making it ideal for safety applications and protective gear. Its exceptional toughness and ability to withstand extreme conditions without cracking or breaking ensure long-lasting durability in demanding environments. This material also offers excellent optical clarity and UV resistance, maintaining performance and appearance over prolonged exposure to sunlight.

Mechanical Strength: High-Impact vs Standard Polycarbonate

High-impact polycarbonate exhibits significantly superior mechanical strength compared to standard polycarbonate, offering enhanced resistance to cracking and deformation under stress. Its molecular structure is engineered to absorb and dissipate energy more effectively, making it ideal for applications requiring durability and impact resistance. Standard polycarbonate, while durable, is more prone to brittle failure under high-impact conditions, limiting its use in demanding environments.

Impact Resistance Comparison

High-impact polycarbonate exhibits superior impact resistance compared to standard polycarbonate, with a notable increase in toughness and ability to absorb energy without cracking. This enhanced durability makes high-impact polycarbonate ideal for applications requiring robust protection, such as safety helmets, protective shields, and automotive parts. Standard polycarbonate, while still strong, tends to have lower impact resistance and is more prone to stress-related damage under extreme conditions.

Durability in Harsh Environments

High-impact polycarbonate exhibits superior durability in harsh environments compared to standard polycarbonate, thanks to its enhanced molecular structure that resists cracking and deformation under extreme stress. This material maintains its clarity and strength under prolonged exposure to UV radiation, chemicals, and temperature fluctuations, making it ideal for industrial and outdoor applications. Standard polycarbonate, while still robust, is more susceptible to surface scratching and impact damage when subjected to aggressive environmental conditions.

Optical Clarity and Light Transmission

High-impact polycarbonate offers superior optical clarity with enhanced resistance to stress crazing compared to standard polycarbonate, making it ideal for applications requiring clear, durable materials. Light transmission in high-impact polycarbonate remains consistently high, often exceeding 88%, ensuring excellent visibility and minimal color distortion. Standard polycarbonate, while still maintaining good light transmission, may show slight optical variations under mechanical stress or impact.

Thermal Stability and Temperature Performance

High-impact polycarbonate exhibits superior thermal stability compared to standard polycarbonate, maintaining structural integrity at temperatures up to 135degC, whereas standard grades typically soften around 130degC. Enhanced temperature performance of high-impact polycarbonate enables better resistance to thermal deformation and prolonged durability in high-heat environments. This makes high-impact variants ideal for applications requiring robust mechanical strength under elevated temperatures, such as automotive components and electronics housings.

Cost and Value Considerations

High-impact polycarbonate offers significantly enhanced durability compared to standard polycarbonate, justifying its higher initial cost through extended lifespan and improved resistance to impact damage. While standard polycarbonate is more budget-friendly upfront, its lower toughness can result in more frequent replacements, increasing long-term expenses. Evaluating total cost of ownership highlights the superior value of high-impact polycarbonate in applications requiring robust performance and longevity.

Choosing the Right Polycarbonate for Your Application

High-impact polycarbonate offers superior durability and resistance to fracture, making it ideal for applications requiring enhanced safety and toughness, such as protective gear and automotive parts. Standard polycarbonate provides excellent clarity and UV resistance, suitable for general-purpose uses like glazing and electronic displays. Selecting the right polycarbonate depends on balancing factors such as impact resistance, optical clarity, and cost efficiency tailored to specific project requirements.

High-impact Polycarbonate vs Standard Polycarbonate Infographic

materialdif.com

materialdif.com