Polycarbonate lamination involves fusing multiple polycarbonate layers with an adhesive film to enhance durability and impact resistance, making it ideal for protective applications. Polycarbonate bonding uses chemical or mechanical methods to join sheets without an intermediate layer, providing a seamless and transparent finish suitable for aesthetic or functional designs. Choosing between lamination and bonding depends on the required strength, clarity, and application environment.

Table of Comparison

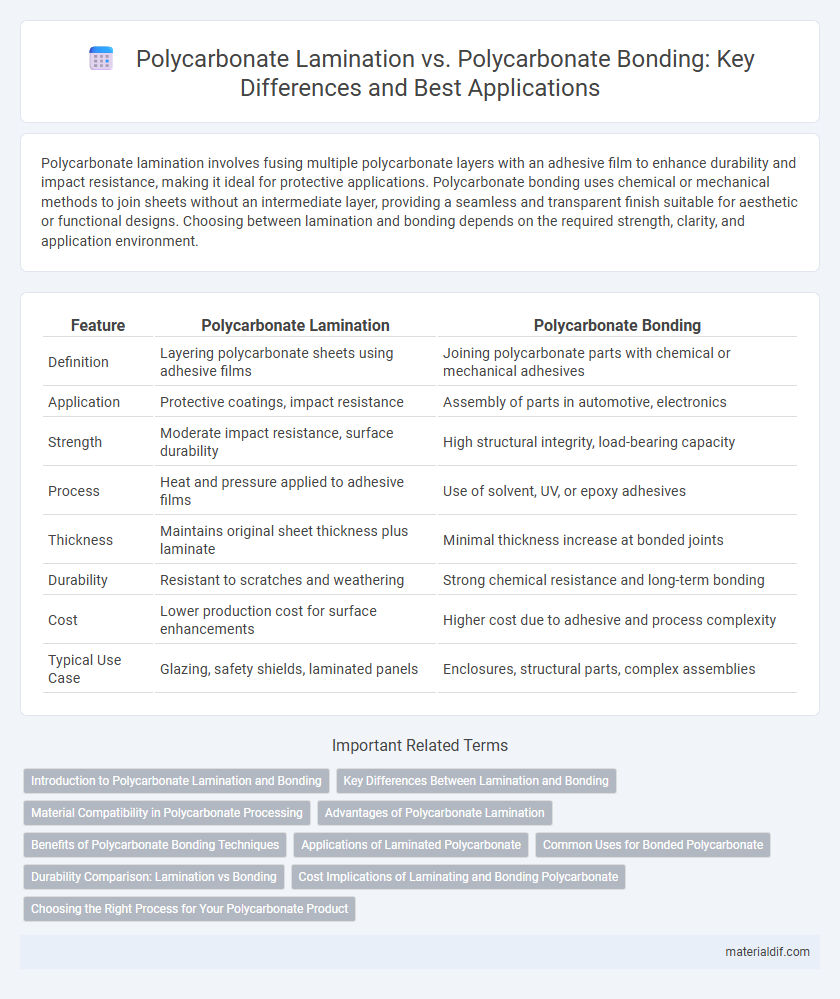

| Feature | Polycarbonate Lamination | Polycarbonate Bonding |

|---|---|---|

| Definition | Layering polycarbonate sheets using adhesive films | Joining polycarbonate parts with chemical or mechanical adhesives |

| Application | Protective coatings, impact resistance | Assembly of parts in automotive, electronics |

| Strength | Moderate impact resistance, surface durability | High structural integrity, load-bearing capacity |

| Process | Heat and pressure applied to adhesive films | Use of solvent, UV, or epoxy adhesives |

| Thickness | Maintains original sheet thickness plus laminate | Minimal thickness increase at bonded joints |

| Durability | Resistant to scratches and weathering | Strong chemical resistance and long-term bonding |

| Cost | Lower production cost for surface enhancements | Higher cost due to adhesive and process complexity |

| Typical Use Case | Glazing, safety shields, laminated panels | Enclosures, structural parts, complex assemblies |

Introduction to Polycarbonate Lamination and Bonding

Polycarbonate lamination involves applying a protective film or layer to enhance surface durability, UV resistance, and scratch protection, preserving the material's optical clarity and impact strength. Polycarbonate bonding uses adhesives or thermal processes to join multiple polycarbonate layers or components, creating strong, seamless assemblies with superior mechanical integrity. Both techniques optimize polycarbonate's versatility in applications like glazing, automotive parts, and electronics by improving performance and longevity.

Key Differences Between Lamination and Bonding

Polycarbonate lamination involves layering thin sheets of polycarbonate with adhesives to create a composite material, enhancing impact resistance and optical clarity. In contrast, polycarbonate bonding uses chemical or mechanical means to join two or more polycarbonate pieces seamlessly without additional layers, yielding a stronger, more durable joint. The key differences include lamination offering improved surface protection and appearance, while bonding emphasizes structural integrity and load-bearing capacity.

Material Compatibility in Polycarbonate Processing

Polycarbonate lamination involves layering polycarbonate sheets with adhesives or films to enhance surface durability and impact resistance, ensuring compatibility with a range of substrates such as acrylic and PET. Polycarbonate bonding typically uses solvent welding or ultrasonic techniques to fuse surfaces, requiring precise material compatibility to prevent stress cracking or weakening. Understanding the chemical composition and thermal properties of polycarbonate and bonding agents is crucial for optimal processing and long-term performance.

Advantages of Polycarbonate Lamination

Polycarbonate lamination offers superior impact resistance and enhanced optical clarity by fusing multiple layers into a single, durable sheet, making it ideal for security and safety applications. This process improves UV protection and weather resistance compared to bonding, ensuring longer-lasting performance in outdoor environments. Laminated polycarbonate also provides better sound insulation and increased structural integrity, reducing the risk of delamination common in bonded materials.

Benefits of Polycarbonate Bonding Techniques

Polycarbonate bonding techniques offer superior structural integrity and enhanced durability compared to lamination, providing stronger adhesion between polycarbonate layers that resist delamination under stress. These bonding methods improve optical clarity and impact resistance, making them ideal for high-performance applications such as automotive glazing and protective equipment. Furthermore, bonded polycarbonate assemblies exhibit better thermal stability and chemical resistance, ensuring long-lasting performance in demanding environments.

Applications of Laminated Polycarbonate

Laminated polycarbonate is widely used in bullet-resistant windows, automotive windshields, and safety glazing due to its enhanced impact resistance and clarity. This lamination process combines multiple polycarbonate layers with adhesives to improve durability and UV protection for long-term outdoor applications. Industries such as aerospace, construction, and security glazing rely on laminated polycarbonate for its superior strength and optical performance.

Common Uses for Bonded Polycarbonate

Bonded polycarbonate is widely used in automotive glazing, bulletproof windows, and electronic display covers, offering enhanced strength and clarity. This bonding method ensures superior impact resistance and weather durability compared to lamination. It is preferred in applications requiring structural integrity and long-lasting performance under stress.

Durability Comparison: Lamination vs Bonding

Polycarbonate lamination involves applying a protective film over the surface, enhancing scratch resistance and UV protection, which extends the material's durability against environmental factors. Polycarbonate bonding creates a polymer-to-polymer adhesive layer that provides superior mechanical strength and chemical resistance, making the bond more resilient under stress and impact. Durability comparison shows bonding typically offers stronger, longer-lasting joints ideal for structural applications, while lamination is better suited for surface protection and aesthetic maintenance.

Cost Implications of Laminating and Bonding Polycarbonate

Polycarbonate lamination typically incurs higher initial costs due to the use of specialized films and heat-pressing equipment, but it offers enhanced surface protection and durability, potentially reducing long-term maintenance expenses. Polycarbonate bonding generally involves lower upfront costs as it uses adhesives or solvents, yet the longevity and strength of bonded joints may require more frequent repairs or replacements, increasing overall life-cycle costs. Evaluating project-specific durability requirements and budget constraints is crucial for choosing between lamination and bonding to optimize cost-efficiency.

Choosing the Right Process for Your Polycarbonate Product

Choosing between polycarbonate lamination and polycarbonate bonding depends on the desired durability and application of your product. Lamination involves layering polycarbonate sheets with adhesives to enhance impact resistance and UV protection, making it ideal for outdoor and high-stress environments. Bonding, typically using solvent or adhesive techniques, provides a seamless, strong joint suited for intricate designs and structural integrity without adding significant thickness.

Polycarbonate Lamination vs Polycarbonate Bonding Infographic

materialdif.com

materialdif.com