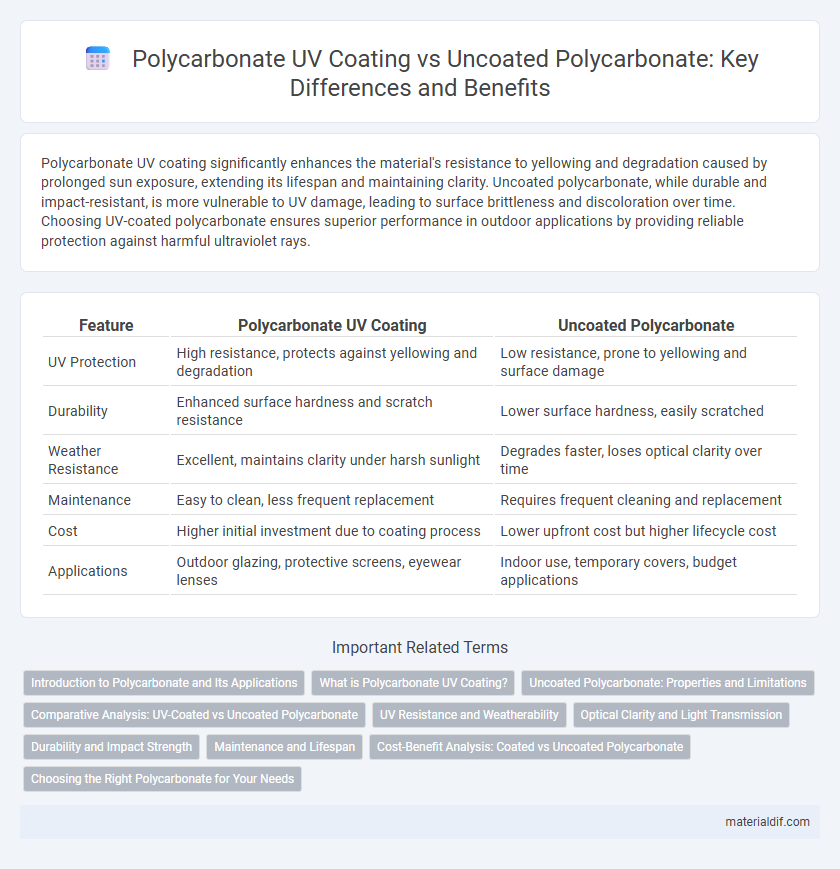

Polycarbonate UV coating significantly enhances the material's resistance to yellowing and degradation caused by prolonged sun exposure, extending its lifespan and maintaining clarity. Uncoated polycarbonate, while durable and impact-resistant, is more vulnerable to UV damage, leading to surface brittleness and discoloration over time. Choosing UV-coated polycarbonate ensures superior performance in outdoor applications by providing reliable protection against harmful ultraviolet rays.

Table of Comparison

| Feature | Polycarbonate UV Coating | Uncoated Polycarbonate |

|---|---|---|

| UV Protection | High resistance, protects against yellowing and degradation | Low resistance, prone to yellowing and surface damage |

| Durability | Enhanced surface hardness and scratch resistance | Lower surface hardness, easily scratched |

| Weather Resistance | Excellent, maintains clarity under harsh sunlight | Degrades faster, loses optical clarity over time |

| Maintenance | Easy to clean, less frequent replacement | Requires frequent cleaning and replacement |

| Cost | Higher initial investment due to coating process | Lower upfront cost but higher lifecycle cost |

| Applications | Outdoor glazing, protective screens, eyewear lenses | Indoor use, temporary covers, budget applications |

Introduction to Polycarbonate and Its Applications

Polycarbonate is a durable, lightweight thermoplastic widely used in applications requiring impact resistance and optical clarity, such as automotive parts, eyewear lenses, and electronic components. UV-coated polycarbonate enhances surface protection by adding a thin, transparent layer that resists yellowing, scratching, and UV degradation, extending the lifespan of outdoor and high-exposure products. Uncoated polycarbonate, while cost-effective and inherently strong, may degrade faster under UV exposure, limiting its use in prolonged sunlight or harsh environmental conditions.

What is Polycarbonate UV Coating?

Polycarbonate UV coating is a thin, transparent layer applied to polycarbonate surfaces to protect against ultraviolet (UV) radiation, significantly reducing yellowing and degradation caused by prolonged sun exposure. This coating enhances the material's durability, maintaining clarity and structural integrity in outdoor and high-UV environments. Uncoated polycarbonate, while inherently robust, is more susceptible to UV damage, leading to faster discoloration and brittleness over time.

Uncoated Polycarbonate: Properties and Limitations

Uncoated polycarbonate features high impact resistance, excellent clarity, and heat resistance but is vulnerable to UV radiation, which causes yellowing and surface degradation over time. Without UV coating, the material's lifespan diminishes when exposed to prolonged sunlight, limiting its suitability for outdoor applications. Its natural brittleness under UV exposure necessitates protective treatments to maintain optical quality and mechanical integrity.

Comparative Analysis: UV-Coated vs Uncoated Polycarbonate

Polycarbonate UV coating significantly enhances the material's resistance to yellowing and surface degradation caused by prolonged exposure to ultraviolet radiation, extending its lifespan in outdoor applications. Uncoated polycarbonate tends to suffer from UV-induced brittleness and discoloration within months, compromising optical clarity and mechanical strength. The comparative analysis underscores that UV-coated polycarbonate is ideal for long-term durability and maintenance of transparency, making it more cost-effective despite higher initial costs.

UV Resistance and Weatherability

Polycarbonate UV coating significantly enhances the material's UV resistance by providing a protective layer that prevents yellowing and degradation caused by prolonged sun exposure. Uncoated polycarbonate, while inherently impact-resistant, tends to degrade faster under UV radiation, leading to reduced clarity and structural integrity over time. The weatherability of UV-coated polycarbonate extends the lifespan of outdoor applications by maintaining optical clarity and mechanical properties despite harsh environmental conditions.

Optical Clarity and Light Transmission

Polycarbonate UV coating enhances optical clarity by reducing surface scratches and maintaining high light transmission rates, typically above 90%, compared to uncoated polycarbonate which may experience reduced clarity due to abrasion over time. The UV coating also protects against yellowing caused by prolonged exposure to ultraviolet rays, preserving the material's transparency and ensuring consistent light transmission. Uncoated polycarbonate, while initially clear, tends to degrade faster under UV exposure, leading to diminished optical performance and lower light transmittance.

Durability and Impact Strength

Polycarbonate UV coating significantly enhances the material's durability by providing a protective layer against UV radiation, preventing yellowing and surface degradation over time. Uncoated polycarbonate, while inherently impact-resistant with a high tensile strength of around 60 MPa, is more susceptible to surface scratching and UV-related wear, reducing its lifespan in outdoor applications. The UV-coated variant maintains impact strength similar to uncoated polycarbonate but offers superior resistance to environmental damage, making it ideal for long-term use in harsh sunlight conditions.

Maintenance and Lifespan

Polycarbonate UV coating significantly enhances the material's resistance to yellowing, scratches, and environmental degradation, extending its lifespan up to 10 years compared to uncoated polycarbonate, which tends to degrade within 3-5 years under UV exposure. Maintenance for UV-coated polycarbonate is minimal, requiring only occasional cleaning with mild soap and water, while uncoated polycarbonate demands more frequent inspections and replacement due to faster surface deterioration. Choosing UV-coated polycarbonate reduces long-term costs and maintenance efforts by preserving optical clarity and structural integrity in outdoor or high-UV environments.

Cost-Benefit Analysis: Coated vs Uncoated Polycarbonate

Polycarbonate UV coating significantly enhances material durability by protecting against yellowing and UV-induced degradation, extending the lifespan of applications exposed to sunlight. The initial cost of UV-coated polycarbonate is higher, but it reduces maintenance and replacement expenses over time, offering better long-term value compared to uncoated polycarbonate. Uncoated polycarbonate presents a lower upfront cost but may incur higher lifecycle costs due to susceptibility to UV damage and consequent material brittleness or discoloration.

Choosing the Right Polycarbonate for Your Needs

Polycarbonate UV coating significantly enhances the material's resistance to yellowing, weathering, and scratches, making it ideal for outdoor applications exposed to sunlight. Uncoated polycarbonate offers cost savings but is more susceptible to UV degradation and surface damage, limiting its lifespan in harsh environments. Selecting between coated and uncoated polycarbonate depends on the specific exposure conditions, durability requirements, and budget constraints of your project.

Polycarbonate UV Coating vs Uncoated Polycarbonate Infographic

materialdif.com

materialdif.com