Polycarbonate and Makrolon are often compared due to their shared durability, impact resistance, and clarity, but Makrolon is a branded type of polycarbonate known for its consistent high quality and superior UV resistance. While polycarbonate serves well in general applications, Makrolon's patented manufacturing process offers enhanced thermal stability and a wider range of customizable grades suitable for demanding industrial uses. Choosing between polycarbonate and Makrolon depends on specific requirements like exposure to harsh environments and performance longevity.

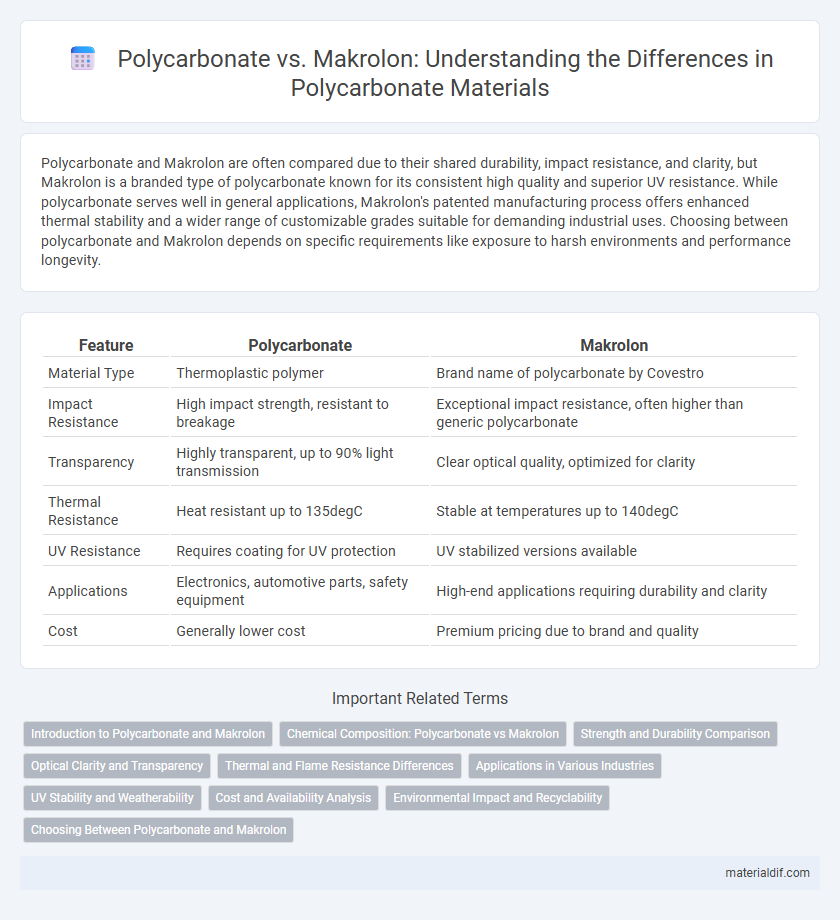

Table of Comparison

| Feature | Polycarbonate | Makrolon |

|---|---|---|

| Material Type | Thermoplastic polymer | Brand name of polycarbonate by Covestro |

| Impact Resistance | High impact strength, resistant to breakage | Exceptional impact resistance, often higher than generic polycarbonate |

| Transparency | Highly transparent, up to 90% light transmission | Clear optical quality, optimized for clarity |

| Thermal Resistance | Heat resistant up to 135degC | Stable at temperatures up to 140degC |

| UV Resistance | Requires coating for UV protection | UV stabilized versions available |

| Applications | Electronics, automotive parts, safety equipment | High-end applications requiring durability and clarity |

| Cost | Generally lower cost | Premium pricing due to brand and quality |

Introduction to Polycarbonate and Makrolon

Polycarbonate is a durable, impact-resistant thermoplastic widely used in automotive, construction, and electronics industries due to its clarity and high strength. Makrolon, a premium brand of polycarbonate produced by Covestro, offers enhanced UV resistance, superior mechanical properties, and consistent quality for demanding applications. Both materials share the same chemical base but Makrolon is engineered for specialized performance standards.

Chemical Composition: Polycarbonate vs Makrolon

Polycarbonate and Makrolon share a similar chemical composition, both primarily made from bisphenol A and phosgene through polymerization, resulting in a tough, transparent thermoplastic. Makrolon is a trademarked brand of polycarbonate produced by Covestro, ensuring consistent chemical purity and molecular weight distribution for superior performance. Variations in additives and processing between generic polycarbonate and Makrolon influence properties like UV resistance, impact strength, and clarity.

Strength and Durability Comparison

Polycarbonate is a high-performance thermoplastic known for exceptional impact resistance and durability, often used in demanding industrial applications. Makrolon, a specific brand of polycarbonate by Covestro, offers superior strength with enhanced UV resistance and improved long-term durability compared to generic polycarbonate grades. Both materials provide excellent toughness, but Makrolon typically delivers enhanced mechanical properties tailored for extreme environmental conditions.

Optical Clarity and Transparency

Polycarbonate and Makrolon are both renowned for their exceptional optical clarity and high transparency, with Makrolon often recognized as a premium brand of polycarbonate known for even superior light transmission. Polycarbonate typically offers over 90% light transmittance, while Makrolon excels with minimal haze and excellent color stability, enhancing visual performance in applications like eyewear lenses and automotive glazing. The advanced manufacturing processes behind Makrolon result in consistently clearer, more transparent sheets, making it ideal for demanding optical uses where precise light clarity is critical.

Thermal and Flame Resistance Differences

Polycarbonate exhibits excellent thermal stability with a heat deflection temperature around 135degC, while Makrolon, a renowned brand of polycarbonate, offers enhanced flame resistance meeting UL 94 V-0 standards. The flame retardant properties in Makrolon are often improved through proprietary additives, making it more suitable for applications requiring stringent fire safety. Both materials maintain strong performance at elevated temperatures, but Makrolon's specialized formulation provides superior resistance to ignition and flame propagation.

Applications in Various Industries

Polycarbonate, a versatile thermoplastic known for its high impact resistance and optical clarity, serves diverse industries including automotive, electronics, and construction. Makrolon, a leading polycarbonate brand by Covestro, is widely utilized in applications ranging from protective eyewear to transparent roofing due to its superior UV resistance and durability. Both materials enable innovation in medical devices, lighting solutions, and consumer electronics, where strength and transparency are critical.

UV Stability and Weatherability

Polycarbonate and Makrolon are both engineering plastics known for high impact resistance, but Makrolon, a branded polycarbonate by Covestro, offers enhanced UV stability and superior weatherability due to its advanced UV stabilizers and protective coatings. This makes Makrolon especially suitable for outdoor applications where prolonged exposure to sunlight and harsh weather conditions is expected, maintaining clarity and mechanical properties over time. Standard polycarbonate may degrade faster under UV exposure, showing yellowing and reduced durability without additional protective treatments.

Cost and Availability Analysis

Polycarbonate and Makrolon, a brand of polycarbonate produced by Covestro, differ in cost and availability primarily due to brand positioning and supply chains. Polycarbonate generally offers a more cost-effective solution with broad availability from multiple manufacturers, making it a preferred choice for budget-sensitive projects. Makrolon, while typically priced higher due to its certified quality and consistent supply, is widely accessible through specialized distributors, ensuring reliability in critical applications.

Environmental Impact and Recyclability

Polycarbonate and Makrolon, both high-performance thermoplastics, differ in environmental impact and recyclability due to their production processes and chemical formulations. Makrolon, a Braskem-branded polycarbonate, often emphasizes advanced recycling programs and lower carbon footprints through sustainability initiatives compared to generic polycarbonate. Both materials are recyclable, but Makrolon's specific recycling infrastructure and certifications may offer improved environmental benefits and circular economy integration.

Choosing Between Polycarbonate and Makrolon

Polycarbonate and Makrolon, both known for exceptional impact resistance and clarity, differ primarily in brand-specific formulations and certifications. Makrolon, a premium polycarbonate manufactured by Covestro, offers enhanced UV protection and compliance with stringent industry standards, making it ideal for outdoor and safety applications. Choosing between them depends on application requirements such as durability, transparency, thermal stability, and regulatory approvals.

Polycarbonate vs Makrolon Infographic

materialdif.com

materialdif.com