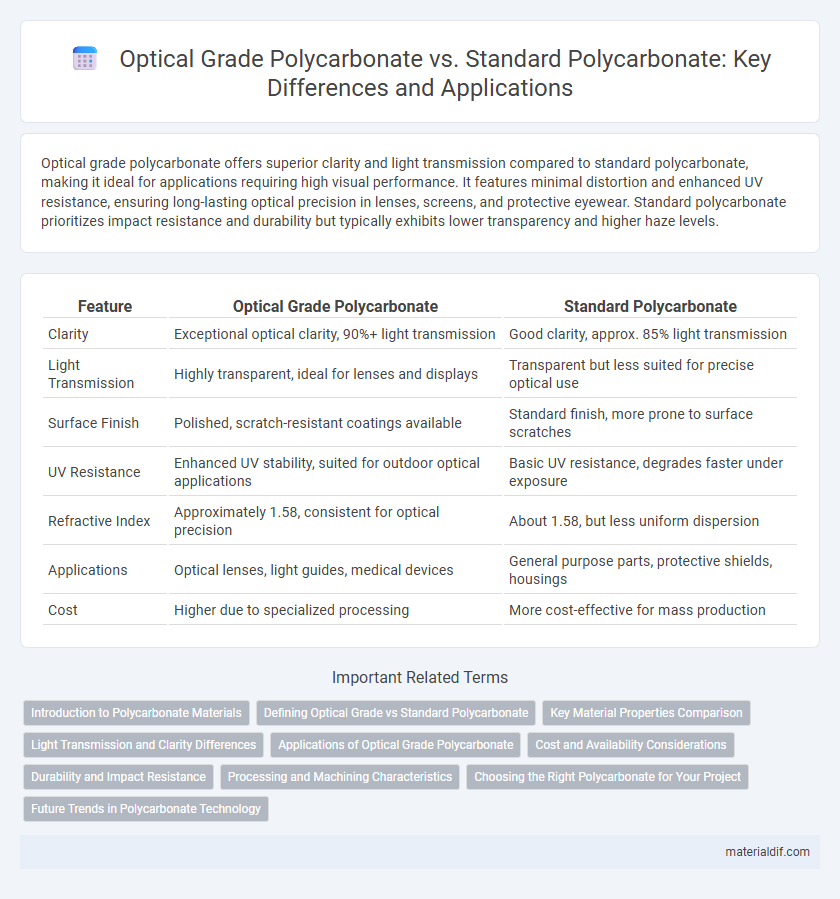

Optical grade polycarbonate offers superior clarity and light transmission compared to standard polycarbonate, making it ideal for applications requiring high visual performance. It features minimal distortion and enhanced UV resistance, ensuring long-lasting optical precision in lenses, screens, and protective eyewear. Standard polycarbonate prioritizes impact resistance and durability but typically exhibits lower transparency and higher haze levels.

Table of Comparison

| Feature | Optical Grade Polycarbonate | Standard Polycarbonate |

|---|---|---|

| Clarity | Exceptional optical clarity, 90%+ light transmission | Good clarity, approx. 85% light transmission |

| Light Transmission | Highly transparent, ideal for lenses and displays | Transparent but less suited for precise optical use |

| Surface Finish | Polished, scratch-resistant coatings available | Standard finish, more prone to surface scratches |

| UV Resistance | Enhanced UV stability, suited for outdoor optical applications | Basic UV resistance, degrades faster under exposure |

| Refractive Index | Approximately 1.58, consistent for optical precision | About 1.58, but less uniform dispersion |

| Applications | Optical lenses, light guides, medical devices | General purpose parts, protective shields, housings |

| Cost | Higher due to specialized processing | More cost-effective for mass production |

Introduction to Polycarbonate Materials

Optical grade polycarbonate offers superior transparency, exceptional light transmission up to 90%, and enhanced impact resistance compared to standard polycarbonate, making it ideal for precision lenses and optical components. Standard polycarbonate provides robust mechanical strength, thermal stability, and cost-effectiveness suited for general-purpose applications such as automotive parts and electronic housings. Both materials share a base composition of bisphenol A and phosgene, but optical grade polycarbonate undergoes specialized processing to achieve clarity and minimal birefringence essential in high-performance optical uses.

Defining Optical Grade vs Standard Polycarbonate

Optical grade polycarbonate is engineered for superior clarity, light transmission, and minimal distortion, making it ideal for lenses, eyewear, and optical components. Standard polycarbonate offers robust impact resistance and durability but lacks the precise optical properties required for clarity-intensive applications. The key distinction lies in the stringent manufacturing controls and material purity in optical grade polycarbonate that ensure consistent refractive index and transparency.

Key Material Properties Comparison

Optical grade polycarbonate offers superior light transmission exceeding 90%, compared to standard polycarbonate's 85%, making it ideal for optical lenses and glazing applications. It exhibits enhanced surface clarity and lower haze levels, ensuring minimal light distortion critical in precision optics. Both materials share high impact resistance and thermal stability, but optical grade's improved optical properties and scratch resistance differentiate it significantly for advanced optical uses.

Light Transmission and Clarity Differences

Optical grade polycarbonate offers superior light transmission rates of up to 90%, significantly higher than the 85% typically found in standard polycarbonate, resulting in enhanced clarity and visual performance. This material features fewer impurities and minimal haze, ensuring sharper image quality and greater color accuracy crucial for optical applications. In contrast, standard polycarbonate may exhibit slight cloudiness and lower transparency, making it less ideal for precision lenses and high-definition displays.

Applications of Optical Grade Polycarbonate

Optical grade polycarbonate offers superior clarity, light transmission, and minimal birefringence, making it ideal for precision lenses, optical discs, and eyewear lenses. This specialized material is extensively used in medical devices, automotive headlamps, and display screens where optical performance is critical. Compared to standard polycarbonate, optical grade variants ensure enhanced visual accuracy and durability in high-demand optical applications.

Cost and Availability Considerations

Optical grade polycarbonate typically incurs higher costs compared to standard polycarbonate due to its superior clarity, precise manufacturing processes, and stringent quality control standards. Availability of optical grade polycarbonate may be limited as it is specialized for applications requiring high optical performance, whereas standard polycarbonate is widely produced and accessible for general use. Budget constraints and supply chain considerations often guide the choice between optical grade and standard polycarbonate materials in industrial and commercial applications.

Durability and Impact Resistance

Optical grade polycarbonate offers superior durability and enhanced impact resistance compared to standard polycarbonate, making it ideal for applications requiring clarity and robustness. Its specialized formulation resists yellowing and maintains optical clarity under high-stress environments, outperforming standard variants in toughness. This combination of durability and impact resistance ensures longer lifespan and reliability in safety-critical uses like lenses, visors, and protective shields.

Processing and Machining Characteristics

Optical grade polycarbonate offers superior clarity and minimal birefringence, making it ideal for precision lenses and optical components, while standard polycarbonate suits general-purpose applications due to its balanced properties. Precise machining of optical grade polycarbonate requires controlled processing parameters to avoid stress-induced distortions, whereas standard polycarbonate is more forgiving during cutting, drilling, and machining. The improved dimensional stability and scratch resistance of optical grade variants demand specialized equipment and techniques to maintain surface quality during fabrication.

Choosing the Right Polycarbonate for Your Project

Optical grade polycarbonate offers superior light transmission and clarity, making it ideal for applications such as lenses, displays, and protective eyewear where visual precision is critical. Standard polycarbonate provides robust impact resistance and durability suitable for general-purpose uses like automotive parts, electronic housings, and construction materials. Selecting the right polycarbonate depends on project requirements for transparency, optical clarity, and mechanical strength to ensure optimal performance and longevity.

Future Trends in Polycarbonate Technology

Optical grade polycarbonate exhibits superior optical clarity and scratch resistance compared to standard polycarbonate, driving its adoption in advanced electronics and eyewear. Innovations in UV stabilization and anti-reflective coatings are enhancing the performance of optical grade variants, making them more durable and suitable for diverse applications. Future trends indicate a shift towards bio-based polycarbonate materials and smart polymers integrated with sensors, expanding the functional capabilities of optical grade polycarbonate products.

Optical grade polycarbonate vs Standard polycarbonate Infographic

materialdif.com

materialdif.com