Flame retardant polycarbonate offers enhanced fire resistance by incorporating specialized additives that reduce flammability without compromising the material's strength and clarity. Standard polycarbonate, while durable and impact-resistant, lacks these fire-retardant properties, making it less suitable for applications with strict fire safety requirements. Selecting flame retardant polycarbonate ensures compliance with safety standards and improves performance in high-risk environments.

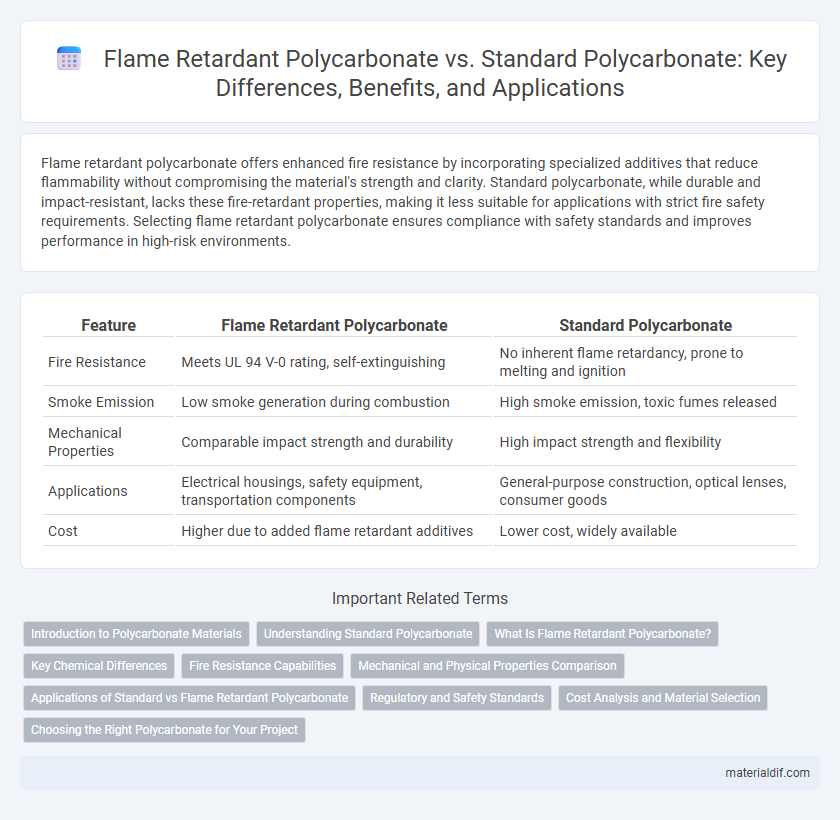

Table of Comparison

| Feature | Flame Retardant Polycarbonate | Standard Polycarbonate |

|---|---|---|

| Fire Resistance | Meets UL 94 V-0 rating, self-extinguishing | No inherent flame retardancy, prone to melting and ignition |

| Smoke Emission | Low smoke generation during combustion | High smoke emission, toxic fumes released |

| Mechanical Properties | Comparable impact strength and durability | High impact strength and flexibility |

| Applications | Electrical housings, safety equipment, transportation components | General-purpose construction, optical lenses, consumer goods |

| Cost | Higher due to added flame retardant additives | Lower cost, widely available |

Introduction to Polycarbonate Materials

Flame retardant polycarbonate is engineered by incorporating specific additives that enhance its resistance to ignition and reduce flammability, making it ideal for applications requiring strict fire safety standards. Standard polycarbonate offers excellent impact resistance, transparency, and thermal stability but lacks inherent flame retardant properties. Understanding the compositional differences between flame retardant and standard polycarbonate is crucial for selecting the appropriate material in electronics, automotive, and construction industries where fire performance is critical.

Understanding Standard Polycarbonate

Standard polycarbonate is a versatile thermoplastic known for its high impact resistance, optical clarity, and thermal stability, making it ideal for applications such as eyewear lenses and automotive components. Unlike flame retardant polycarbonate, it lacks inherent fire-resistant additives, which limits its use in environments requiring stringent fire safety standards. Understanding the material properties of standard polycarbonate helps in selecting appropriate applications where flame resistance is not a critical factor.

What Is Flame Retardant Polycarbonate?

Flame retardant polycarbonate is a specialized type of polycarbonate that has been chemically modified to resist ignition and inhibit the spread of fire, meeting stringent flammability standards such as UL 94 V-0. Unlike standard polycarbonate, which offers inherent toughness and transparency but limited fire resistance, flame retardant variants incorporate halogen-free flame retardants or additives like ATH (aluminum trihydrate) to enhance thermal stability and reduce smoke generation. This material is widely used in applications requiring strict fire safety compliance, including electrical enclosures, automotive components, and electronic housings.

Key Chemical Differences

Flame retardant polycarbonate contains halogenated or phosphorus-based additives that disrupt combustion processes, significantly reducing flammability compared to standard polycarbonate. Standard polycarbonate primarily consists of bisphenol A-based polymers with minimal inherent fire resistance, making it more prone to rapid ignition and smoke generation. The incorporation of flame retardant compounds alters the polymer matrix, enhancing thermal stability and limiting heat release during exposure to fire.

Fire Resistance Capabilities

Flame retardant polycarbonate is engineered with specific additives that significantly enhance its fire resistance, achieving UL 94 V-0 ratings that prevent ignition and inhibit flame spread. Standard polycarbonate lacks these specialized formulations, making it more susceptible to melting and burning under high temperatures. The fire resistance capabilities of flame retardant polycarbonate make it ideal for applications requiring stringent safety standards, such as electrical enclosures and automotive parts.

Mechanical and Physical Properties Comparison

Flame retardant polycarbonate exhibits enhanced fire resistance while maintaining comparable mechanical strength and impact resistance to standard polycarbonate. The addition of flame retardant additives can slightly reduce tensile strength and elongation at break but improves thermal stability and reduces smoke emission during combustion. Standard polycarbonate provides excellent optical clarity and toughness, whereas flame retardant variants balance these properties with increased flame resistance for safety-critical applications.

Applications of Standard vs Flame Retardant Polycarbonate

Standard polycarbonate is widely used in automotive parts, eyewear lenses, and electronic housings due to its high impact resistance and optical clarity. Flame retardant polycarbonate is essential in electrical and electronic components, building materials, and transportation applications requiring enhanced fire safety and compliance with strict fire regulations. The flame retardant variants provide critical protection in environments where fire hazards are a concern, while standard polycarbonate excels in general use scenarios without stringent fire resistance demands.

Regulatory and Safety Standards

Flame retardant polycarbonate complies with stringent regulatory standards such as UL 94 V-0, indicating superior resistance to ignition and self-extinguishing capabilities compared to standard polycarbonate which typically meets UL 94 V-2 or lower ratings. Regulatory frameworks including REACH and RoHS often mandate the use of flame retardant grades in electrical and electronic applications to minimize fire hazards and toxic fume emissions. Safety compliance ensures that flame retardant polycarbonate is preferred in industries requiring enhanced fire protection, such as automotive, aerospace, and consumer electronics manufacturing.

Cost Analysis and Material Selection

Flame retardant polycarbonate typically incurs higher upfront costs compared to standard polycarbonate due to the incorporation of specialized additives and enhanced manufacturing processes designed to meet stringent fire safety standards. Cost analysis reveals that while standard polycarbonate offers economical advantages for general applications, flame retardant variants provide long-term value by reducing fire-related risks and potential regulatory compliance expenses. Material selection decisions should weigh initial expenditure against safety requirements, application environment, and compliance mandates, with flame retardant polycarbonate favored in industries demanding rigorous fire resistance.

Choosing the Right Polycarbonate for Your Project

Flame retardant polycarbonate offers enhanced safety by meeting stringent fire resistance standards, making it ideal for applications in electronics, construction, and transportation where fire hazards are a concern. Standard polycarbonate provides excellent impact resistance and optical clarity but lacks the fire-resistant properties required for high-risk environments. Selecting the appropriate polycarbonate requires assessing project-specific safety requirements, regulatory compliance, and environmental conditions.

Flame Retardant Polycarbonate vs Standard Polycarbonate Infographic

materialdif.com

materialdif.com