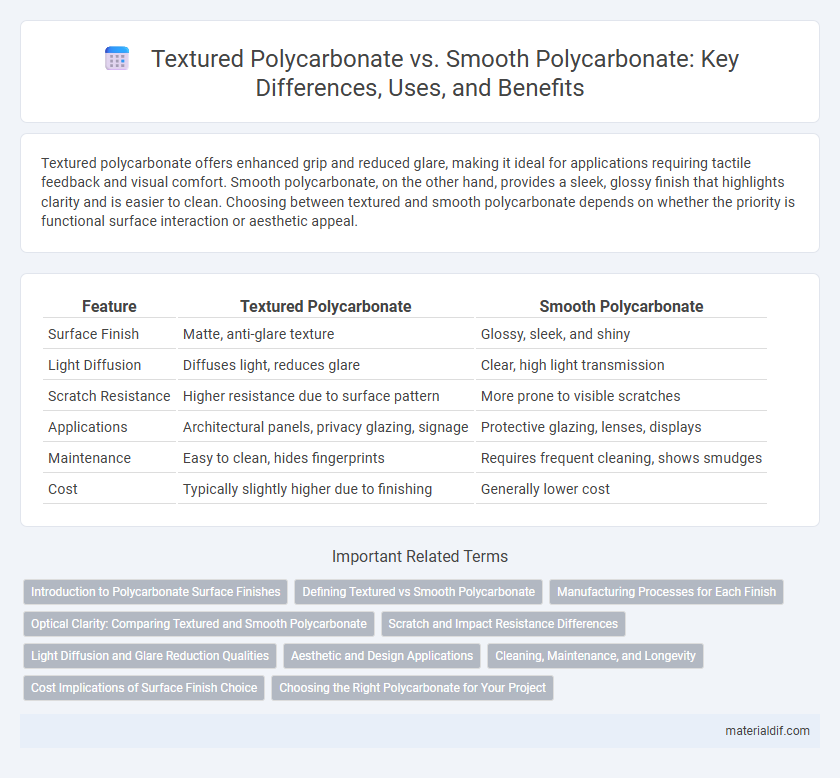

Textured polycarbonate offers enhanced grip and reduced glare, making it ideal for applications requiring tactile feedback and visual comfort. Smooth polycarbonate, on the other hand, provides a sleek, glossy finish that highlights clarity and is easier to clean. Choosing between textured and smooth polycarbonate depends on whether the priority is functional surface interaction or aesthetic appeal.

Table of Comparison

| Feature | Textured Polycarbonate | Smooth Polycarbonate |

|---|---|---|

| Surface Finish | Matte, anti-glare texture | Glossy, sleek, and shiny |

| Light Diffusion | Diffuses light, reduces glare | Clear, high light transmission |

| Scratch Resistance | Higher resistance due to surface pattern | More prone to visible scratches |

| Applications | Architectural panels, privacy glazing, signage | Protective glazing, lenses, displays |

| Maintenance | Easy to clean, hides fingerprints | Requires frequent cleaning, shows smudges |

| Cost | Typically slightly higher due to finishing | Generally lower cost |

Introduction to Polycarbonate Surface Finishes

Textured polycarbonate surfaces offer enhanced light diffusion, reduced glare, and improved scratch resistance compared to smooth polycarbonate, making them ideal for applications requiring both durability and aesthetic appeal. Smooth polycarbonate provides a clear, transparent finish that maximizes light transmission and clarity, widely used in glazing and protective covers. Understanding the differences in surface finishes is essential for selecting the right polycarbonate type based on optical properties, tactile feel, and environmental performance.

Defining Textured vs Smooth Polycarbonate

Textured polycarbonate features a patterned or embossed surface designed to enhance grip, reduce glare, and obscure visibility, making it ideal for privacy and aesthetic applications. Smooth polycarbonate provides a clear, glossy finish that offers high optical clarity and is commonly used for windows, lenses, and protective barriers. The choice between textured and smooth polycarbonate depends on functional requirements such as light diffusion, abrasion resistance, and visual transparency.

Manufacturing Processes for Each Finish

Textured polycarbonate is produced using specialized molds or embossing rollers that imprint patterns during the injection molding or extrusion processes, enhancing grip and reducing glare. Smooth polycarbonate results from precision polishing or using ultra-smooth molds, creating a sleek, transparent surface ideal for optical clarity in applications like lenses and shields. Manufacturing for each finish requires tailored cooling rates and mold surface treatments to achieve the desired texture without compromising material properties.

Optical Clarity: Comparing Textured and Smooth Polycarbonate

Smooth polycarbonate offers superior optical clarity with minimal light distortion, making it ideal for applications demanding clear visibility such as lenses and protective screens. Textured polycarbonate diffuses light, reducing glare and hiding fingerprints or scratches but sacrificing some transparency. Choosing between textured and smooth polycarbonate depends on the balance needed between clarity and surface finish in the end use.

Scratch and Impact Resistance Differences

Textured polycarbonate surfaces offer enhanced scratch resistance by diffusing abrasions across irregular patterns, reducing visible damage compared to smooth polycarbonate, which shows scratches more prominently. Both textured and smooth polycarbonate maintain high impact resistance due to the polymer's inherent toughness, but the textured finish can help conceal minor impact marks better. Smooth polycarbonate is preferred when optical clarity is critical, while textured variants balance durability and aesthetics in high-contact environments.

Light Diffusion and Glare Reduction Qualities

Textured polycarbonate panels enhance light diffusion by scattering light more evenly, reducing harsh shadows and minimizing glare, making them ideal for environments requiring soft, uniform illumination. Smooth polycarbonate, while offering higher clarity and light transmission, tends to produce more direct glare due to its flat surface, which can cause visual discomfort in bright settings. Choosing textured polycarbonate improves glare reduction and visual comfort in applications such as skylights and light fixtures where diffused light is critical.

Aesthetic and Design Applications

Textured polycarbonate offers enhanced surface depth and visual interest, making it ideal for architectural panels and decorative installations where tactile appeal is crucial. Smooth polycarbonate, with its sleek and reflective finish, suits modern design applications requiring clarity and minimal visual disruption, such as glazing and protective covers. Designers often select textured finishes to conceal fingerprints and scratches, while smooth surfaces emphasize transparency and clean lines in aesthetic construction.

Cleaning, Maintenance, and Longevity

Textured polycarbonate surfaces resist fingerprints, scratches, and minor abrasions better than smooth polycarbonate, reducing cleaning frequency and effort. Smooth polycarbonate tends to show smudges and dirt more prominently, requiring more regular maintenance and gentle cleaning agents to avoid surface damage. Textured finishes enhance longevity by minimizing visible wear, while smooth surfaces need careful upkeep to maintain clarity and durability over time.

Cost Implications of Surface Finish Choice

Textured polycarbonate typically incurs higher production costs due to the specialized molds and additional processing required to achieve the surface pattern, impacting overall material expenses. Smooth polycarbonate is generally more cost-effective, benefiting from simpler manufacturing steps and faster production cycles. Choosing between textured and smooth finishes directly influences budget considerations in applications where both aesthetic and functional surface properties are critical.

Choosing the Right Polycarbonate for Your Project

Textured polycarbonate offers enhanced grip, reduced glare, and increased scratch resistance, making it ideal for applications requiring durability and aesthetic appeal, such as outdoor panels or automotive parts. Smooth polycarbonate provides superior clarity and a sleek finish, perfect for optical components, windows, and protective covers where transparency is crucial. Assessing project needs for visibility, surface durability, and environmental exposure ensures selecting the right polycarbonate type for optimal performance and longevity.

Textured Polycarbonate vs Smooth Polycarbonate Infographic

materialdif.com

materialdif.com