Polycarbonate offers superior impact resistance compared to glass, making it ideal for applications requiring durability and safety. Unlike glass, polycarbonate is lightweight and shatterproof, reducing the risk of injury or damage. It also provides excellent optical clarity, maintaining transparency while being more flexible and easier to mold than traditional glass.

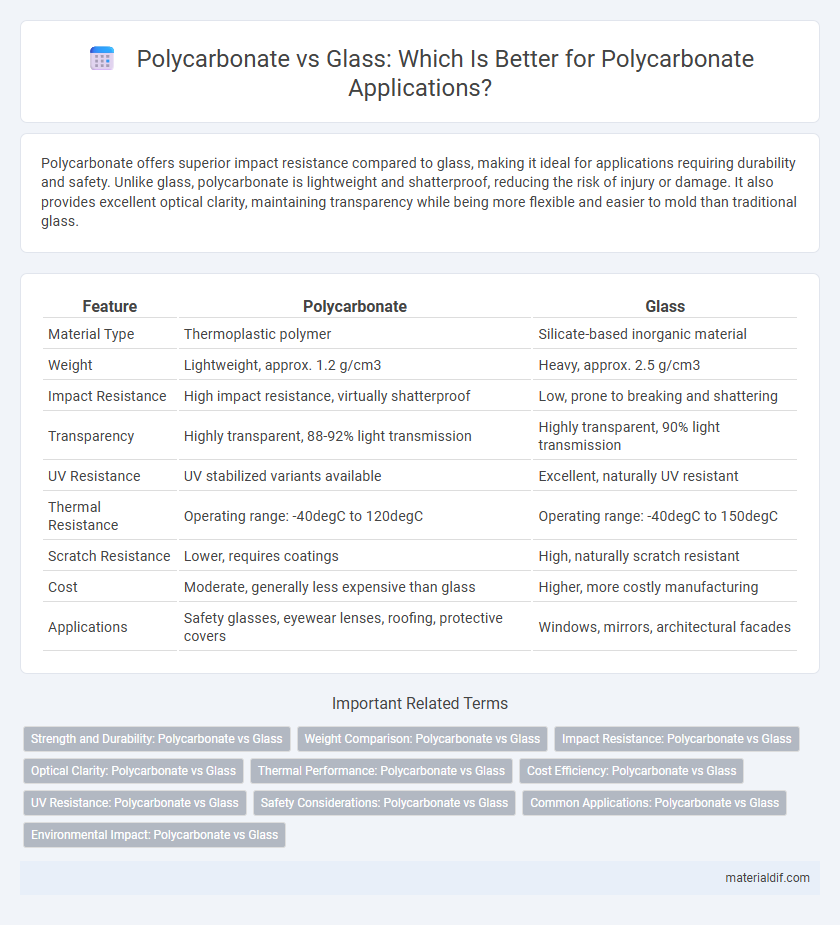

Table of Comparison

| Feature | Polycarbonate | Glass |

|---|---|---|

| Material Type | Thermoplastic polymer | Silicate-based inorganic material |

| Weight | Lightweight, approx. 1.2 g/cm3 | Heavy, approx. 2.5 g/cm3 |

| Impact Resistance | High impact resistance, virtually shatterproof | Low, prone to breaking and shattering |

| Transparency | Highly transparent, 88-92% light transmission | Highly transparent, 90% light transmission |

| UV Resistance | UV stabilized variants available | Excellent, naturally UV resistant |

| Thermal Resistance | Operating range: -40degC to 120degC | Operating range: -40degC to 150degC |

| Scratch Resistance | Lower, requires coatings | High, naturally scratch resistant |

| Cost | Moderate, generally less expensive than glass | Higher, more costly manufacturing |

| Applications | Safety glasses, eyewear lenses, roofing, protective covers | Windows, mirrors, architectural facades |

Strength and Durability: Polycarbonate vs Glass

Polycarbonate exhibits exceptional strength, being approximately 250 times stronger than glass, which makes it highly impact-resistant and virtually shatterproof. Unlike glass, polycarbonate maintains durability under extreme conditions without cracking or breaking, making it ideal for applications requiring long-lasting performance. Its lightweight nature combined with superior toughness ensures enhanced safety and longevity compared to traditional glass materials.

Weight Comparison: Polycarbonate vs Glass

Polycarbonate is significantly lighter than glass, weighing approximately 30% of the weight of an equivalent glass panel. This substantial weight difference makes polycarbonate an ideal material for applications where reducing structural load and enhancing portability are critical. Its lightweight nature contributes to easier handling, faster installation, and lower transportation costs compared to glass.

Impact Resistance: Polycarbonate vs Glass

Polycarbonate offers significantly higher impact resistance than glass, withstanding impacts up to 250 times greater without cracking or shattering. This makes polycarbonate an ideal choice for applications requiring durability and safety, such as protective eyewear, automotive parts, and security glazing. Glass, while more scratch-resistant, is brittle and prone to breakage under sudden impact, limiting its use in high-impact environments.

Optical Clarity: Polycarbonate vs Glass

Polycarbonate offers high impact resistance but typically has lower optical clarity compared to glass, which provides superior light transmission and minimal distortion. Glass maintains better durability against scratches and chemical exposure, enhancing its long-term clarity. Advanced coatings on polycarbonate can improve optical performance but still fall short of the pristine transparency glass provides.

Thermal Performance: Polycarbonate vs Glass

Polycarbonate offers superior thermal insulation compared to glass, with a lower thermal conductivity value of approximately 0.20 W/m*K versus glass's 1.0 W/m*K, reducing heat transfer significantly. This enhanced thermal performance results in better energy efficiency for buildings using polycarbonate panels, maintaining indoor temperatures more effectively. Polycarbonate's ability to withstand temperature fluctuations without cracking also surpasses glass, contributing to its durability in thermal stress environments.

Cost Efficiency: Polycarbonate vs Glass

Polycarbonate offers superior cost efficiency compared to glass due to its lower material and transportation expenses, as well as reduced installation costs. Its lightweight nature minimizes structural support requirements, leading to additional savings in construction projects. Polycarbonate's durability and impact resistance decrease maintenance and replacement costs over time, making it a more economical choice for long-term applications.

UV Resistance: Polycarbonate vs Glass

Polycarbonate offers superior UV resistance compared to traditional glass, featuring built-in UV inhibitors that block harmful ultraviolet rays and prevent material degradation. Glass, while naturally transparent, often requires additional coatings or treatments to enhance its UV protection, which can wear off over time. This inherent UV-blocking property makes polycarbonate an ideal choice for applications requiring long-term exposure to sunlight without yellowing or loss of structural integrity.

Safety Considerations: Polycarbonate vs Glass

Polycarbonate offers superior impact resistance compared to glass, reducing the risk of shattering and injury in accidents or break-ins. Its high tensile strength makes it nearly unbreakable, whereas glass can easily crack or fragment upon impact, posing safety hazards. This makes polycarbonate an ideal choice for environments requiring enhanced safety measures, such as schools, sports facilities, and security applications.

Common Applications: Polycarbonate vs Glass

Polycarbonate is widely used in applications requiring high impact resistance and lightweight properties, such as safety goggles, automotive headlamps, and riot shields. Glass remains the preferred material for windows, architectural facades, and optical lenses due to its superior scratch resistance and clarity. In construction and electronics, polycarbonate offers flexibility and durability, while glass provides excellent thermal stability and aesthetic appeal.

Environmental Impact: Polycarbonate vs Glass

Polycarbonate generates significantly lower carbon emissions during production compared to traditional glass, due to its lightweight and energy-efficient manufacturing process. Its durability and impact resistance reduce the need for frequent replacements, minimizing waste and resource consumption over time. Glass, while highly recyclable, requires intensive energy use for melting and shaping, resulting in a larger environmental footprint throughout its lifecycle.

Polycarbonate vs Glass Infographic

materialdif.com

materialdif.com