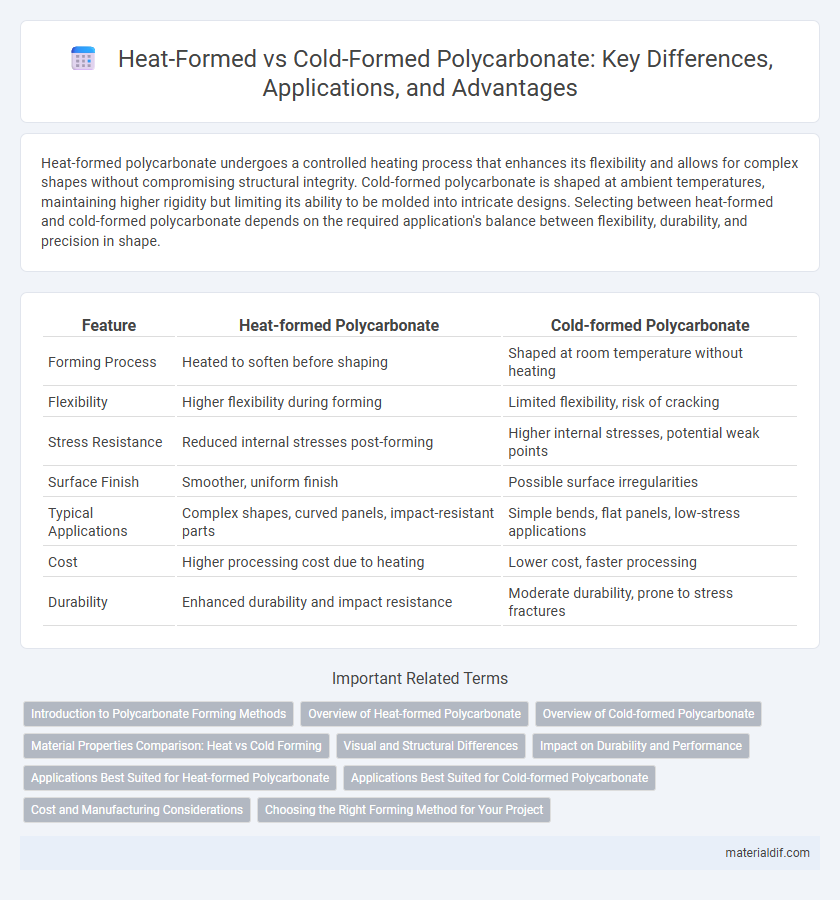

Heat-formed polycarbonate undergoes a controlled heating process that enhances its flexibility and allows for complex shapes without compromising structural integrity. Cold-formed polycarbonate is shaped at ambient temperatures, maintaining higher rigidity but limiting its ability to be molded into intricate designs. Selecting between heat-formed and cold-formed polycarbonate depends on the required application's balance between flexibility, durability, and precision in shape.

Table of Comparison

| Feature | Heat-formed Polycarbonate | Cold-formed Polycarbonate |

|---|---|---|

| Forming Process | Heated to soften before shaping | Shaped at room temperature without heating |

| Flexibility | Higher flexibility during forming | Limited flexibility, risk of cracking |

| Stress Resistance | Reduced internal stresses post-forming | Higher internal stresses, potential weak points |

| Surface Finish | Smoother, uniform finish | Possible surface irregularities |

| Typical Applications | Complex shapes, curved panels, impact-resistant parts | Simple bends, flat panels, low-stress applications |

| Cost | Higher processing cost due to heating | Lower cost, faster processing |

| Durability | Enhanced durability and impact resistance | Moderate durability, prone to stress fractures |

Introduction to Polycarbonate Forming Methods

Heat-formed polycarbonate undergoes controlled heating to become pliable, enabling complex shapes with high structural integrity, while cold-formed polycarbonate is shaped at room temperature using mechanical force, which preserves material clarity but limits design flexibility. The heat-forming process enhances stress resistance and impact strength, making it suitable for applications requiring durability and intricate forms. Cold forming is preferred for simpler designs where transparency and minimal thermal distortion are critical, such as in protective covers and glazing.

Overview of Heat-formed Polycarbonate

Heat-formed polycarbonate is a thermoplastic material shaped by applying controlled heat to soften the sheets, allowing precise molding into complex curves and shapes without compromising clarity or strength. This process enhances impact resistance and provides excellent thermal stability, making it suitable for automotive components, glazing applications, and architectural elements. Its superior flexibility during shaping ensures minimal internal stress, resulting in durable, high-performance finished products.

Overview of Cold-formed Polycarbonate

Cold-formed polycarbonate maintains its structural integrity without the application of heat, preserving inherent strength and impact resistance ideal for manufacturing rigid panels and protective barriers. This method reduces the risk of thermal deformation, ensuring dimensional stability and consistent optical clarity in applications such as glazing and signage. Its efficient production process supports cost-effective fabrication while delivering durable, lightweight materials suitable for weather-resistant construction.

Material Properties Comparison: Heat vs Cold Forming

Heat-formed polycarbonate exhibits enhanced flexibility and improved impact resistance due to the softened molecular structure during the heating process, allowing more precise shaping without compromising clarity. Cold-formed polycarbonate maintains higher tensile strength and stiffness because the molecular chains remain rigid, which can result in more pronounced residual stresses and potential brittleness under stress. The choice between heat-formed and cold-formed polycarbonate directly affects durability, dimensional stability, and optical properties, influencing application suitability in eyewear, automotive parts, and glazing panels.

Visual and Structural Differences

Heat-formed polycarbonate exhibits enhanced clarity and uniform thickness, resulting in superior visual quality and reduced optical distortion compared to cold-formed polycarbonate. Structurally, heat-forming improves the polymer's flexibility and impact resistance by relieving internal stresses, while cold-formed polycarbonate tends to retain residual stress that can cause warping or reduced durability. The differences in processing directly influence the material's performance in applications requiring high transparency and mechanical strength.

Impact on Durability and Performance

Heat-formed polycarbonate exhibits enhanced molecular alignment, resulting in superior impact resistance and greater dimensional stability compared to cold-formed polycarbonate. Cold-formed polycarbonate, lacking thermal shaping, may present increased internal stresses that reduce its long-term durability under mechanical strain. Performance in applications exposed to fluctuating temperatures and heavy impacts favors heat-formed variants due to their improved structural integrity and resistance to deformation.

Applications Best Suited for Heat-formed Polycarbonate

Heat-formed polycarbonate is ideal for applications requiring complex shapes and precise bends, such as automotive components, medical devices, and architectural glazing. Its enhanced flexibility during the heating process allows for intricate designs without compromising material strength or clarity. This makes heat-formed polycarbonate the preferred choice for custom fabrication, durable protective barriers, and ergonomically designed consumer products.

Applications Best Suited for Cold-formed Polycarbonate

Cold-formed polycarbonate excels in applications requiring high impact resistance and rigidity without exposure to elevated temperatures, making it ideal for bullet-resistant barriers, machine guards, and protective glazing in security installations. Its superior dimensional stability under ambient conditions suits use in greenhouses, skylights, and signage where transparency and durability are critical. Cold-formed polycarbonate's ability to maintain structural integrity without heat treatment ensures cost-effective production for industrial and architectural solutions demanding toughness and clarity.

Cost and Manufacturing Considerations

Heat-formed polycarbonate requires higher energy input, increasing production costs compared to cold-formed polycarbonate, which uses lower temperatures and simpler equipment. Manufacturing heat-formed polycarbonate involves controlled heating and precise molding to achieve complex shapes, while cold-formed polycarbonate allows faster production with reduced tooling expenses but is limited to less intricate designs. Choosing between heat-formed and cold-formed polycarbonate depends on balancing upfront manufacturing investments and the desired complexity of the final product.

Choosing the Right Forming Method for Your Project

Heat-formed polycarbonate offers superior flexibility and impact resistance, making it ideal for complex shapes and curved designs in architectural or automotive applications. Cold-formed polycarbonate retains higher rigidity and dimensional stability, suitable for projects requiring precise tolerances and flat surfaces such as glazing or protective screens. Selecting the appropriate forming method depends on the desired strength, shape complexity, and application-specific performance requirements to ensure optimal durability and functionality.

Heat-formed Polycarbonate vs Cold-formed Polycarbonate Infographic

materialdif.com

materialdif.com