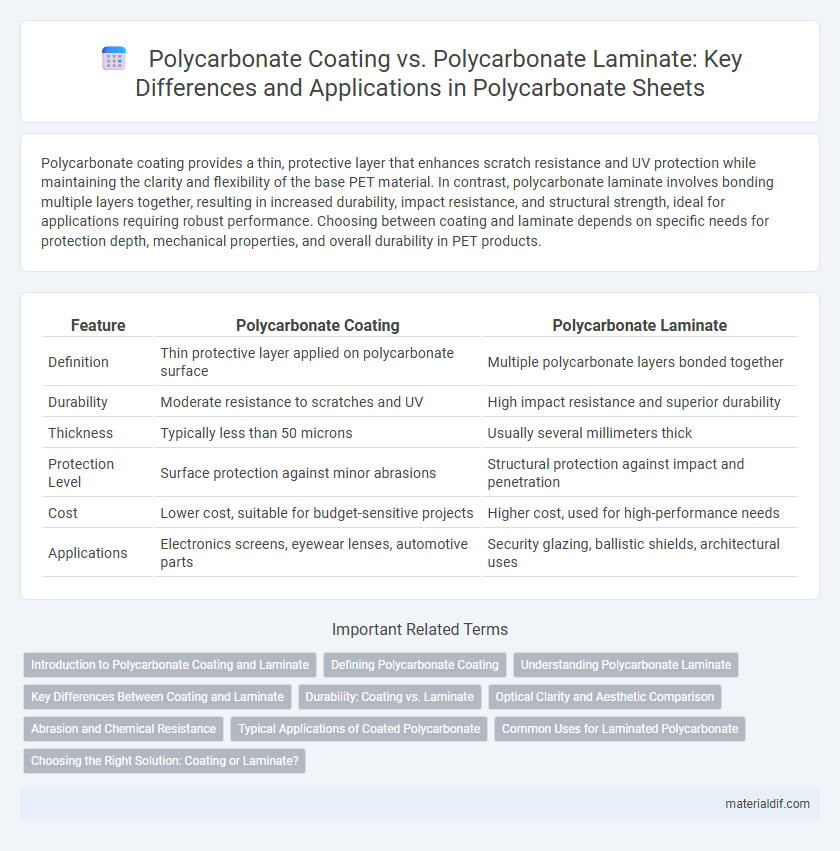

Polycarbonate coating provides a thin, protective layer that enhances scratch resistance and UV protection while maintaining the clarity and flexibility of the base PET material. In contrast, polycarbonate laminate involves bonding multiple layers together, resulting in increased durability, impact resistance, and structural strength, ideal for applications requiring robust performance. Choosing between coating and laminate depends on specific needs for protection depth, mechanical properties, and overall durability in PET products.

Table of Comparison

| Feature | Polycarbonate Coating | Polycarbonate Laminate |

|---|---|---|

| Definition | Thin protective layer applied on polycarbonate surface | Multiple polycarbonate layers bonded together |

| Durability | Moderate resistance to scratches and UV | High impact resistance and superior durability |

| Thickness | Typically less than 50 microns | Usually several millimeters thick |

| Protection Level | Surface protection against minor abrasions | Structural protection against impact and penetration |

| Cost | Lower cost, suitable for budget-sensitive projects | Higher cost, used for high-performance needs |

| Applications | Electronics screens, eyewear lenses, automotive parts | Security glazing, ballistic shields, architectural uses |

Introduction to Polycarbonate Coating and Laminate

Polycarbonate coating involves applying a protective layer on the surface of polycarbonate sheets to enhance scratch resistance and UV protection, extending the material's durability. Polycarbonate laminate consists of bonding multiple layers of polycarbonate or other substrates to improve impact resistance, structural integrity, and acoustic insulation. Both technologies are widely used in automotive, construction, and electronics industries to tailor polycarbonate properties according to specific application requirements.

Defining Polycarbonate Coating

Polycarbonate coating refers to a thin protective layer applied to polycarbonate surfaces to enhance scratch resistance, UV protection, and durability without significantly altering the material's transparency or flexibility. Unlike polycarbonate laminate, which involves bonding multiple layers for increased strength and impact resistance, polycarbonate coating primarily serves as a surface treatment to improve performance and longevity. This coating is commonly used in optical lenses, automotive parts, and electronic displays to maintain clarity while safeguarding the polycarbonate substrate.

Understanding Polycarbonate Laminate

Polycarbonate laminate consists of multiple polycarbonate layers fused together to enhance strength, impact resistance, and durability, providing superior protection compared to single-layer polycarbonate coatings. This laminated structure is often used in applications requiring high security and transparency, such as bulletproof windows and protective barriers. Understanding the composition and advantages of polycarbonate laminate helps in selecting the appropriate solution for enhanced performance and safety requirements.

Key Differences Between Coating and Laminate

Polycarbonate coating provides a thin, protective layer enhancing scratch resistance and UV protection without altering the base material's flexibility or transparency, while polycarbonate laminate involves bonding multiple layers of polycarbonate for increased strength, impact resistance, and thickness. Coatings are typically applied as surface treatments, offering improved durability against environmental damage, whereas laminates create a composite structure designed for heavy-duty applications requiring enhanced mechanical performance. The key differences lie in application method, function, and resulting material properties: coatings enhance surface characteristics, laminates improve overall structural integrity.

Durability: Coating vs. Laminate

Polycarbonate coating provides a protective layer that enhances scratch resistance and UV protection, extending the surface durability of polycarbonate sheets. In contrast, polycarbonate laminate involves bonding multiple layers, significantly improving impact resistance and structural strength for demanding applications. Laminate typically offers superior long-term durability under high-stress or harsh environmental conditions compared to surface coatings.

Optical Clarity and Aesthetic Comparison

Polycarbonate coatings enhance optical clarity by providing a smooth, transparent surface that resists scratches and UV damage, preserving visual quality over time. Polycarbonate laminates offer improved durability with multi-layer construction yet may slightly reduce clarity due to additional adhesive layers that can cause minor light diffusion. Aesthetically, coated polycarbonate maintains a sleek, glossy finish ideal for applications demanding high transparency, while laminated polycarbonate provides greater structural integrity but may appear less visually pristine.

Abrasion and Chemical Resistance

Polycarbonate coating significantly enhances abrasion resistance by forming a hard, protective layer that prevents scratches and surface damage. In contrast, polycarbonate laminate offers improved chemical resistance by incorporating multiple resin layers that create a barrier against solvents and corrosive substances. Optimal durability in industrial and automotive applications often depends on choosing coatings for surface toughness or laminates for chemical resilience.

Typical Applications of Coated Polycarbonate

Polycarbonate coating enhances surface hardness and scratch resistance, making it ideal for eyewear lenses, automotive headlamps, and protective shields in industrial settings. This coating also provides UV protection, extending the lifespan of polycarbonate in outdoor applications like skylights and greenhouse panels. Coated polycarbonate is favored in electronics and medical equipment for its durability and clarity without adding significant weight.

Common Uses for Laminated Polycarbonate

Laminated polycarbonate is commonly used in applications requiring enhanced impact resistance and safety, such as bullet-resistant windows, automotive glazing, and security barriers. Its multi-layer structure improves durability and offers superior protection against shattering compared to standard polycarbonate coating. This makes laminated polycarbonate ideal for architectural glazing, riot shields, and protective eyewear where both strength and clarity are essential.

Choosing the Right Solution: Coating or Laminate?

Polycarbonate coating enhances surface properties such as scratch resistance and UV protection without significantly altering the material's flexibility, making it ideal for applications requiring lightweight durability. Polycarbonate laminate involves bonding multiple layers, improving impact resistance and structural strength for demanding environments. Selecting between coating and laminate depends on whether surface enhancement or reinforced toughness is the primary performance requirement.

Polycarbonate Coating vs Polycarbonate Laminate Infographic

materialdif.com

materialdif.com