Cold bending polycarbonate PET involves shaping the material at room temperature, allowing for precise and sharp curves without the need for heat, which maintains the material's intrinsic strength and clarity. Thermal forming heats the polycarbonate PET to make it pliable, enabling complex three-dimensional shapes but potentially causing slight changes in optical properties and mechanical strength. Choosing between cold bending and thermal forming depends on the desired shape complexity, durability requirements, and budget considerations.

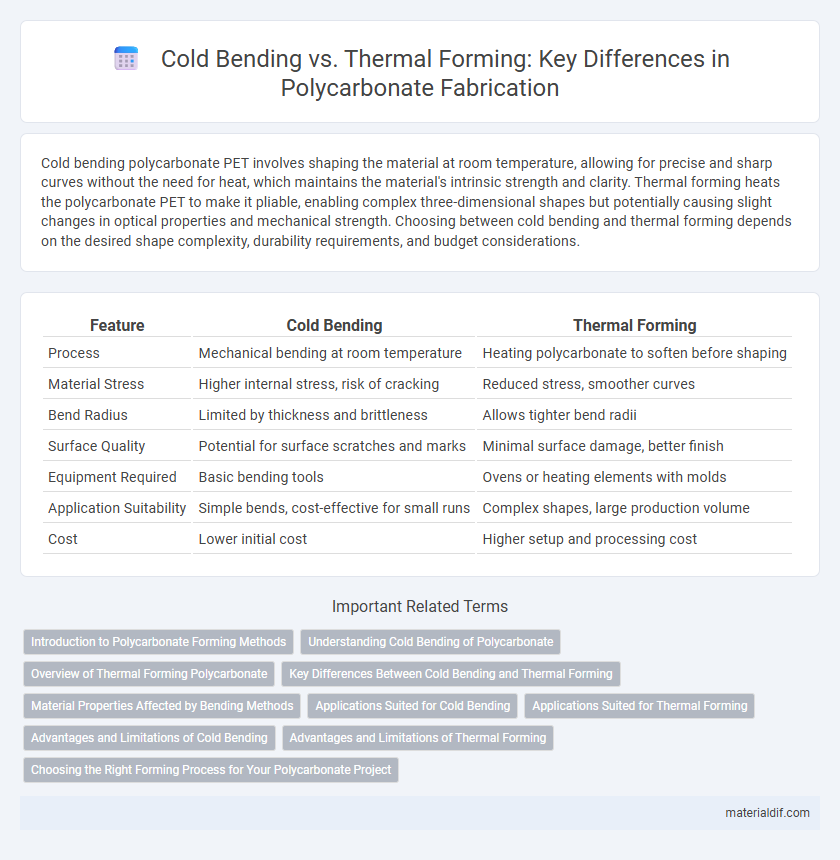

Table of Comparison

| Feature | Cold Bending | Thermal Forming |

|---|---|---|

| Process | Mechanical bending at room temperature | Heating polycarbonate to soften before shaping |

| Material Stress | Higher internal stress, risk of cracking | Reduced stress, smoother curves |

| Bend Radius | Limited by thickness and brittleness | Allows tighter bend radii |

| Surface Quality | Potential for surface scratches and marks | Minimal surface damage, better finish |

| Equipment Required | Basic bending tools | Ovens or heating elements with molds |

| Application Suitability | Simple bends, cost-effective for small runs | Complex shapes, large production volume |

| Cost | Lower initial cost | Higher setup and processing cost |

Introduction to Polycarbonate Forming Methods

Polycarbonate forming methods include cold bending and thermal forming, each offering distinct advantages based on application requirements. Cold bending involves shaping polycarbonate sheets at ambient temperatures, preserving material strength and reducing risk of stress fractures. Thermal forming heats the polycarbonate to a pliable state, enabling complex curves and detailed shapes but requires careful temperature control to prevent deformation or loss of clarity.

Understanding Cold Bending of Polycarbonate

Cold bending of polycarbonate involves shaping the material at room temperature without applying heat, preserving its structural integrity and reducing the risk of thermal distortion. This method relies on the inherent flexibility and toughness of polycarbonate sheets, making it ideal for simple curvature applications and maintaining optical clarity. Unlike thermal forming, cold bending limits the range of achievable shapes but offers faster processing times and lower energy consumption.

Overview of Thermal Forming Polycarbonate

Thermal forming polycarbonate involves heating the material to a specific temperature range, typically between 140degC and 180degC, to achieve flexible shaping without cracking or damaging its structural integrity. This process allows for complex curves and contours, making it ideal for applications requiring precise architectural panels, automotive components, or protective equipment. Compared to cold bending, thermal forming provides enhanced durability and consistent performance by reducing internal stresses and avoiding surface deformation.

Key Differences Between Cold Bending and Thermal Forming

Cold bending polycarbonate involves shaping the material at room temperature, relying on its inherent flexibility and elasticity without altering its molecular structure. Thermal forming heats polycarbonate sheets to a pliable temperature, allowing for more complex shapes and precise contours by temporarily softening the polymer chains. Key differences include temperature requirements, precision of form, and the risk of internal stress or micro-cracking, which is minimized in thermal forming but may occur during cold bending.

Material Properties Affected by Bending Methods

Cold bending of polycarbonate maintains higher impact resistance and structural integrity by avoiding heat-induced molecular changes, though it may introduce residual stresses and slight surface imperfections. Thermal forming softens the polymer, allowing for more complex shapes with reduced stress concentrations but can decrease UV resistance and cause minor reductions in tensile strength due to polymer chain relaxation. Selecting the appropriate bending method depends on balancing desired mechanical properties against form complexity and long-term durability requirements.

Applications Suited for Cold Bending

Cold bending of polycarbonate is ideal for applications requiring precise, small-radius curves without compromising material strength, such as protective barriers, display cases, and architectural facades. This method maintains the inherent durability and impact resistance of the polycarbonate, making it suitable for safety glazing and signage where thermal exposure is limited. Cold bending is preferred for on-site installations and retrofitting projects due to its ease and speed, avoiding the need for specialized heating equipment used in thermal forming.

Applications Suited for Thermal Forming

Thermal forming of polycarbonate is ideal for producing complex shapes and intricate designs commonly required in automotive components, architectural panels, and electronic device enclosures. This method allows the material to be evenly heated and molded without compromising its optical clarity and impact resistance, making it suitable for applications demanding both strength and aesthetic appeal. Industries relying on customized, high-quality polycarbonate parts benefit from thermal forming's precision and versatility over cold bending techniques.

Advantages and Limitations of Cold Bending

Cold bending polycarbonate offers the advantage of maintaining material integrity without the need for heating, reducing the risk of thermal stress or discoloration. It allows for quick installation and cost-effective shaping, particularly for slight curves or angles. However, cold bending is limited by the minimum bend radius, risking cracking or structural weakness if exceeded, making it less suitable for complex or tight-radius shapes compared to thermal forming.

Advantages and Limitations of Thermal Forming

Thermal forming of polycarbonate enables complex shapes and smooth curves by heating the material to increase its pliability, resulting in enhanced design flexibility and improved structural integrity. This process reduces internal stresses and risk of material cracking compared to cold bending, allowing for larger radii and more precise contours. However, thermal forming requires controlled heating equipment and longer processing times, making it less suitable for quick or low-cost applications.

Choosing the Right Forming Process for Your Polycarbonate Project

Cold bending polycarbonate allows for gradual, stress-free shaping ideal for simple curves and cost-effective projects, maintaining the material's structural integrity without heating. Thermal forming involves heating polycarbonate sheets to pliable temperatures above 150degC, enabling complex shapes and detailed designs by softening the material for precise molding. Selecting between cold bending and thermal forming depends on project complexity, desired curvature, and application requirements, with thermal forming suited for intricate designs and cold bending preferred for straightforward shapes and faster turnaround.

Cold bending vs Thermal forming Infographic

materialdif.com

materialdif.com