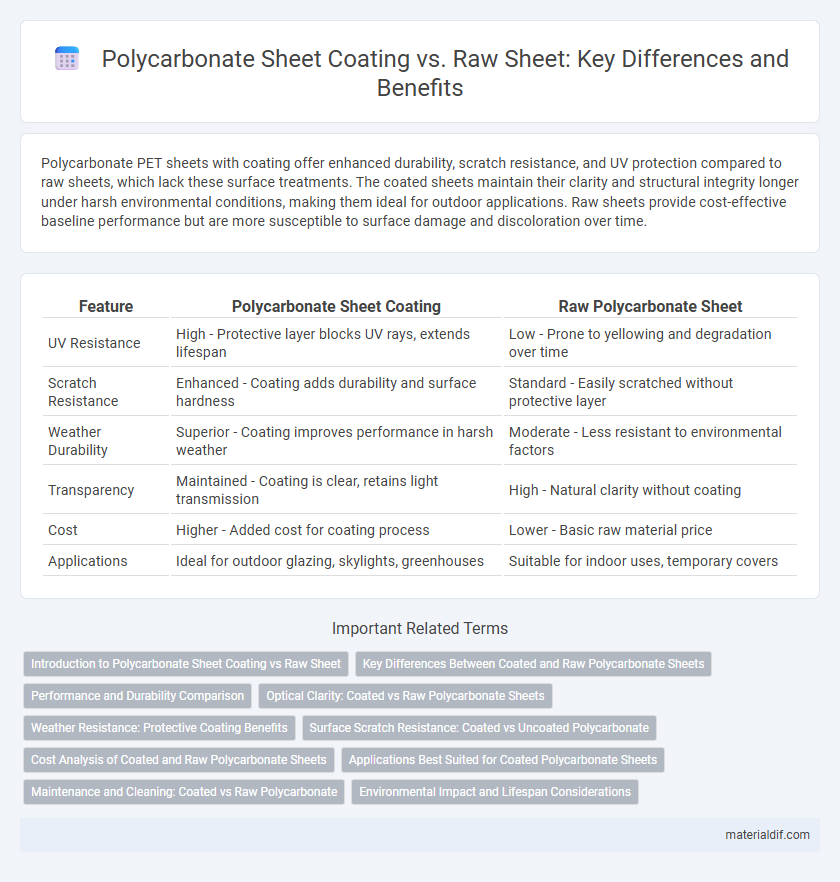

Polycarbonate PET sheets with coating offer enhanced durability, scratch resistance, and UV protection compared to raw sheets, which lack these surface treatments. The coated sheets maintain their clarity and structural integrity longer under harsh environmental conditions, making them ideal for outdoor applications. Raw sheets provide cost-effective baseline performance but are more susceptible to surface damage and discoloration over time.

Table of Comparison

| Feature | Polycarbonate Sheet Coating | Raw Polycarbonate Sheet |

|---|---|---|

| UV Resistance | High - Protective layer blocks UV rays, extends lifespan | Low - Prone to yellowing and degradation over time |

| Scratch Resistance | Enhanced - Coating adds durability and surface hardness | Standard - Easily scratched without protective layer |

| Weather Durability | Superior - Coating improves performance in harsh weather | Moderate - Less resistant to environmental factors |

| Transparency | Maintained - Coating is clear, retains light transmission | High - Natural clarity without coating |

| Cost | Higher - Added cost for coating process | Lower - Basic raw material price |

| Applications | Ideal for outdoor glazing, skylights, greenhouses | Suitable for indoor uses, temporary covers |

Introduction to Polycarbonate Sheet Coating vs Raw Sheet

Polycarbonate sheet coating enhances surface properties such as scratch resistance, UV protection, and chemical durability compared to raw sheets. Raw polycarbonate sheets offer high impact strength and optical clarity but lack the protective layers that prevent surface damage and degradation over time. Coated sheets are ideal for applications requiring extended lifespan and environmental resistance, while raw sheets suit uses where cost efficiency and basic material properties are sufficient.

Key Differences Between Coated and Raw Polycarbonate Sheets

Coated polycarbonate sheets feature a protective layer that enhances UV resistance, scratch resistance, and weather durability compared to raw sheets, which lack these surface treatments. Raw polycarbonate sheets are more vulnerable to environmental damage, such as yellowing and surface abrasion, reducing their lifespan and clarity. The coating significantly improves the sheet's performance in outdoor applications, maintaining optical clarity and structural integrity over prolonged exposure.

Performance and Durability Comparison

Sheet coating enhances polycarbonate's performance by providing superior resistance to UV radiation, scratches, and chemical exposure compared to raw sheets. Coated sheets exhibit increased durability, extending their lifespan in outdoor and harsh environmental conditions, while raw sheets are more susceptible to yellowing, abrasion, and surface degradation. Choosing coated polycarbonate sheets ensures better protection and long-term structural integrity for applications requiring high performance.

Optical Clarity: Coated vs Raw Polycarbonate Sheets

Polycarbonate sheets with specialized optical coatings enhance light transmission and reduce glare, providing superior clarity compared to raw polycarbonate sheets. Coated sheets resist yellowing and maintain optical clarity longer under UV exposure, making them ideal for applications demanding high visual performance. Raw polycarbonate sheets have good initial clarity but are more prone to surface scratching and UV-induced discoloration, which diminishes optical quality over time.

Weather Resistance: Protective Coating Benefits

Polycarbonate sheets with protective coatings exhibit superior weather resistance compared to raw sheets, effectively shielding against UV radiation, moisture, and abrasion. The coatings enhance durability, preventing yellowing and surface degradation over time, which raw sheets are more susceptible to under prolonged environmental exposure. This protective layer extends the lifespan and maintains the clarity and structural integrity critical for applications in outdoor signage, glazing, and roofing.

Surface Scratch Resistance: Coated vs Uncoated Polycarbonate

Coated polycarbonate sheets exhibit significantly enhanced surface scratch resistance compared to raw, uncoated sheets, making them ideal for applications requiring durability and clarity over time. The hard coating layer protects against abrasions, reducing surface damage and maintaining optical quality even under frequent handling or exposure to harsh environments. Uncoated polycarbonate, while impact-resistant, is more susceptible to surface scratches, which can degrade appearance and performance.

Cost Analysis of Coated and Raw Polycarbonate Sheets

Cost analysis reveals that coated polycarbonate sheets typically command higher prices than raw sheets due to added manufacturing processes and materials for UV resistance and scratch protection. Raw polycarbonate sheets offer lower initial costs but may incur higher maintenance or replacement expenses over time in outdoor or harsh environments. Evaluating total lifecycle costs is essential for choosing between coated and raw sheets based on durability and budget constraints.

Applications Best Suited for Coated Polycarbonate Sheets

Coated polycarbonate sheets provide enhanced scratch resistance, UV protection, and improved weatherability, making them ideal for applications such as outdoor signage, greenhouse panels, and protective glazing. Unlike raw sheets, which are more vulnerable to abrasion and discoloration, coated sheets maintain clarity and durability over time in harsh environmental conditions. Industries requiring long-lasting transparency and surface resilience, including automotive, construction, and electronics, benefit significantly from coated polycarbonate materials.

Maintenance and Cleaning: Coated vs Raw Polycarbonate

Coated polycarbonate sheets require less frequent maintenance due to their protective layer that resists scratches, UV damage, and chemical exposure, ensuring longer-lasting clarity and durability. Raw polycarbonate sheets, while initially more cost-effective, demand more rigorous cleaning with non-abrasive agents to prevent surface degradation and yellowing over time. Consistent maintenance of coated sheets minimizes manual labor and extends service life, making them ideal for applications exposed to harsh environmental conditions.

Environmental Impact and Lifespan Considerations

Sheet coating on polycarbonate enhances resistance to UV radiation, extending lifespan by reducing yellowing and surface degradation compared to raw sheets. Coated sheets lower environmental impact by minimizing the frequency of replacements, thereby reducing plastic waste and resource consumption. Raw polycarbonate sheets may require more frequent disposal and replacement, increasing landfill contribution and environmental burden.

Sheet coating vs Raw sheet Infographic

materialdif.com

materialdif.com