Anti-static polycarbonate features a specialized coating that reduces static electricity buildup, preventing dust and debris accumulation, which is essential for applications in electronics and cleanroom environments. Standard polycarbonate lacks this conductive layer, making it prone to attracting dust and particles that can interfere with sensitive equipment. Choosing anti-static polycarbonate enhances durability and cleanliness, ensuring optimal performance in static-sensitive settings.

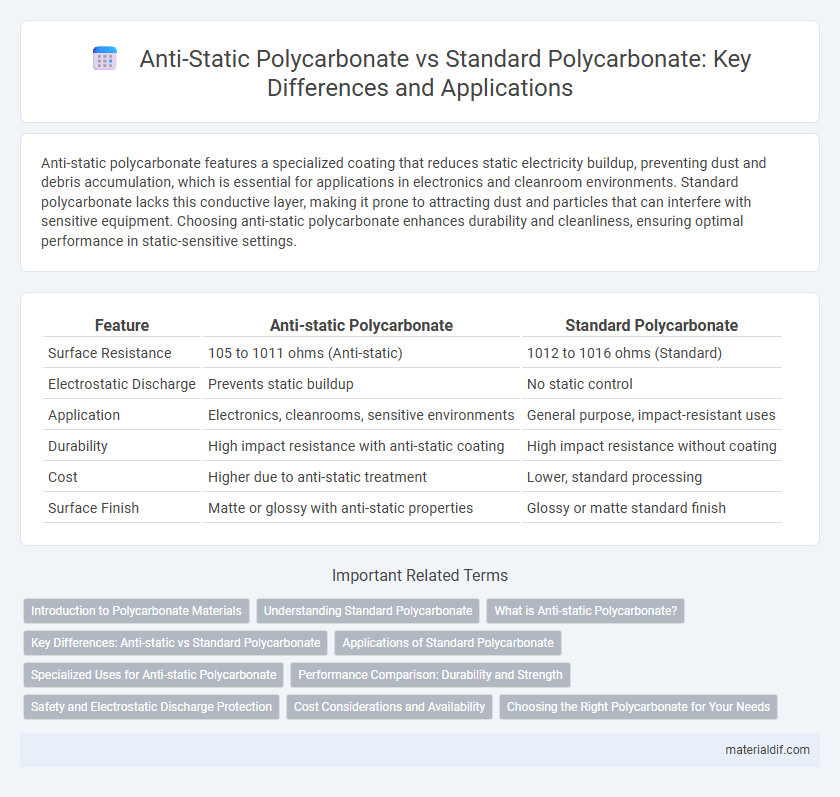

Table of Comparison

| Feature | Anti-static Polycarbonate | Standard Polycarbonate |

|---|---|---|

| Surface Resistance | 105 to 1011 ohms (Anti-static) | 1012 to 1016 ohms (Standard) |

| Electrostatic Discharge | Prevents static buildup | No static control |

| Application | Electronics, cleanrooms, sensitive environments | General purpose, impact-resistant uses |

| Durability | High impact resistance with anti-static coating | High impact resistance without coating |

| Cost | Higher due to anti-static treatment | Lower, standard processing |

| Surface Finish | Matte or glossy with anti-static properties | Glossy or matte standard finish |

Introduction to Polycarbonate Materials

Polycarbonate materials are known for their high impact resistance, optical clarity, and thermal stability, making them versatile in various applications. Anti-static polycarbonate incorporates conductive additives that reduce surface electrical charge buildup, enhancing safety and performance in sensitive electronic and cleanroom environments. Standard polycarbonate lacks these additives, making it more prone to static electricity accumulation, which can attract dust and cause potential damage in specific uses.

Understanding Standard Polycarbonate

Standard polycarbonate is a transparent thermoplastic known for its high impact resistance, optical clarity, and thermal stability, making it suitable for applications such as eyewear lenses, automotive components, and electronic housings. It lacks inherent anti-static properties, which can lead to static charge buildup and dust attraction in sensitive environments. Compared to anti-static polycarbonate, standard polycarbonate offers excellent mechanical strength but requires additional surface treatments or coatings to address static-related issues.

What is Anti-static Polycarbonate?

Anti-static polycarbonate is a specialized type of polycarbonate material engineered to reduce static electricity buildup on its surface, making it ideal for applications sensitive to static discharge such as electronics housing and cleanroom environments. This material incorporates anti-static additives or surface treatments that dissipate electrical charge, preventing dust attraction and improving safety in static-prone areas. Unlike standard polycarbonate, which lacks these properties, anti-static polycarbonate enhances durability and performance where static control is critical.

Key Differences: Anti-static vs Standard Polycarbonate

Anti-static polycarbonate features a conductive coating or additive that dissipates static electricity, preventing dust attraction and reducing the risk of static discharge in sensitive environments. Standard polycarbonate lacks these conductive properties, making it more prone to static buildup and dust accumulation. The key difference lies in anti-static polycarbonate's enhanced ability to control static charge, which is critical for applications in electronics, cleanrooms, and other static-sensitive settings.

Applications of Standard Polycarbonate

Standard polycarbonate is widely used in applications requiring high impact resistance and optical clarity, such as automotive headlamp lenses, eyewear lenses, and protective gear. Its excellent mechanical strength and transparency make it ideal for electronic housings, glazing panels, and optical discs. Although lacking anti-static properties, it performs reliably in environments where static buildup is not a critical concern.

Specialized Uses for Anti-static Polycarbonate

Anti-static polycarbonate is engineered with conductive additives to prevent static electricity buildup, making it essential for environments sensitive to electrostatic discharge (ESD), such as electronic manufacturing and cleanrooms. Unlike standard polycarbonate, which offers high impact resistance and transparency, anti-static variants are critical in semiconductor device production, medical equipment, and explosive handling areas to ensure safety and operational integrity. This specialized use protects delicate components from static damage and reduces contamination risks in controlled environments.

Performance Comparison: Durability and Strength

Anti-static polycarbonate exhibits comparable durability and strength to standard polycarbonate while providing enhanced resistance to dust and static buildup, making it ideal for sensitive electronic environments. Both materials maintain high impact resistance and structural integrity under stress, with anti-static variants offering additional surface protection against electrical discharge damage. The longevity of anti-static polycarbonate in industrial applications often exceeds standard polycarbonate due to its specialized coating that preserves mechanical properties without compromising toughness.

Safety and Electrostatic Discharge Protection

Anti-static polycarbonate offers enhanced safety by effectively dissipating electrostatic charges, reducing the risk of sparks and potential ignition in sensitive environments. Standard polycarbonate lacks this specific property, making it less suitable for applications requiring stringent electrostatic discharge (ESD) protection. Utilizing anti-static polycarbonate in electronic housings, cleanrooms, or industrial settings minimizes static buildup, ensuring safer operation and compliance with ESD standards.

Cost Considerations and Availability

Anti-static polycarbonate typically incurs higher costs than standard polycarbonate due to specialized additives that prevent static buildup, increasing manufacturing complexity. Availability of anti-static variants can be limited compared to standard polycarbonate, as they cater to niche applications in electronics and cleanroom environments. Budget planning should account for these price premiums and potential lead times when sourcing anti-static polycarbonate materials.

Choosing the Right Polycarbonate for Your Needs

Anti-static polycarbonate is designed to prevent dust attraction and reduce static electricity buildup, making it ideal for electronic enclosures and cleanroom applications. Standard polycarbonate offers excellent impact resistance and clarity but lacks the specialized surface properties needed for static-sensitive environments. Selecting the right polycarbonate depends on environmental conditions and specific application requirements, ensuring optimal performance and longevity.

Anti-static Polycarbonate vs Standard Polycarbonate Infographic

materialdif.com

materialdif.com