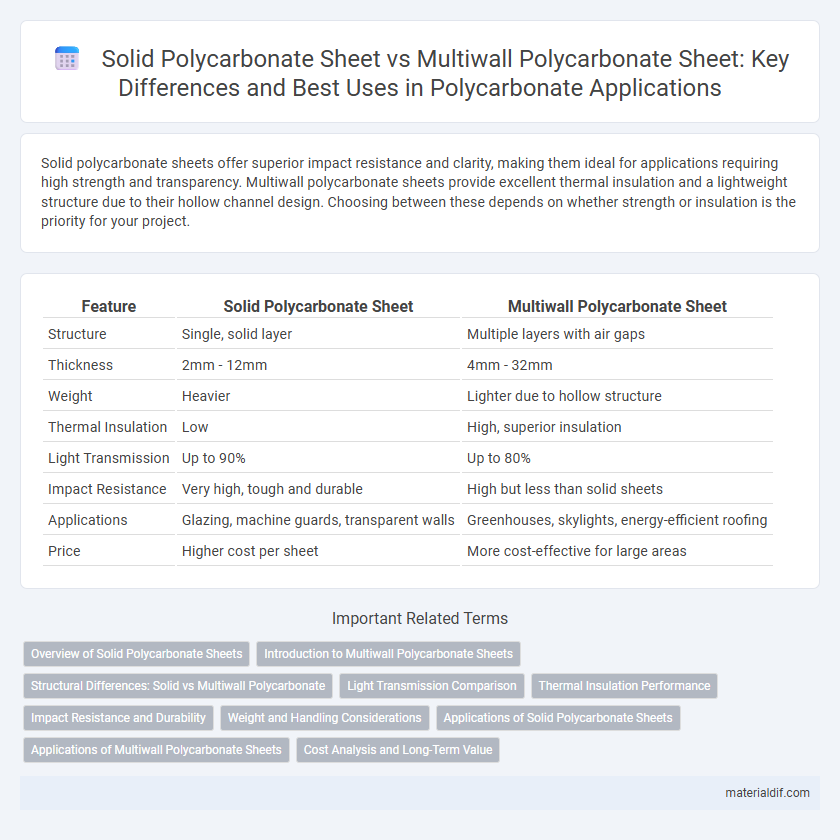

Solid polycarbonate sheets offer superior impact resistance and clarity, making them ideal for applications requiring high strength and transparency. Multiwall polycarbonate sheets provide excellent thermal insulation and a lightweight structure due to their hollow channel design. Choosing between these depends on whether strength or insulation is the priority for your project.

Table of Comparison

| Feature | Solid Polycarbonate Sheet | Multiwall Polycarbonate Sheet |

|---|---|---|

| Structure | Single, solid layer | Multiple layers with air gaps |

| Thickness | 2mm - 12mm | 4mm - 32mm |

| Weight | Heavier | Lighter due to hollow structure |

| Thermal Insulation | Low | High, superior insulation |

| Light Transmission | Up to 90% | Up to 80% |

| Impact Resistance | Very high, tough and durable | High but less than solid sheets |

| Applications | Glazing, machine guards, transparent walls | Greenhouses, skylights, energy-efficient roofing |

| Price | Higher cost per sheet | More cost-effective for large areas |

Overview of Solid Polycarbonate Sheets

Solid polycarbonate sheets offer exceptional impact resistance and clarity, making them ideal for applications requiring high strength and transparency such as protective barriers and glazing. These sheets provide superior thermal insulation and UV protection, ensuring durability in outdoor environments. Solid polycarbonate's dense structure delivers excellent weather resistance and dimensional stability compared to multiwall polycarbonate sheets.

Introduction to Multiwall Polycarbonate Sheets

Multiwall polycarbonate sheets feature a unique cellular structure with multiple layers separated by air gaps, providing enhanced thermal insulation and impact resistance compared to solid polycarbonate sheets. These sheets are significantly lighter, improving ease of installation while maintaining high strength and durability. Ideal for applications requiring light diffusion and energy efficiency, multiwall polycarbonate sheets excel in roofing, skylights, and greenhouses.

Structural Differences: Solid vs Multiwall Polycarbonate

Solid polycarbonate sheets consist of a single, uniform layer providing high impact resistance and excellent clarity, making them ideal for applications requiring strength and transparency. Multiwall polycarbonate sheets feature multiple layers separated by internal ribs, creating air pockets that enhance thermal insulation and reduce weight while maintaining structural rigidity. This layered design differentiates multiwall polycarbonate by offering improved energy efficiency and reduced material thickness compared to solid polycarbonate sheets.

Light Transmission Comparison

Solid polycarbonate sheets offer higher light transmission rates, typically around 85-90%, making them ideal for applications requiring maximum clarity and brightness. Multiwall polycarbonate sheets feature a layered structure that reduces light transmission to approximately 60-75%, providing better insulation and diffused light but less transparency. The choice between solid and multiwall sheets depends on the balance between light clarity needs and thermal performance.

Thermal Insulation Performance

Solid polycarbonate sheets provide excellent impact resistance and clarity but offer moderate thermal insulation, making them suitable for applications where transparency and durability are priorities. Multiwall polycarbonate sheets feature a cellular structure that traps air between layers, significantly enhancing thermal insulation and reducing heat transfer. This design makes multiwall sheets ideal for energy-efficient glazing and roofing solutions where maintaining indoor temperature is critical.

Impact Resistance and Durability

Solid polycarbonate sheets offer superior impact resistance due to their dense, homogenous structure, making them ideal for applications requiring high durability against physical damage. Multiwall polycarbonate sheets, although less impact-resistant, provide enhanced thermal insulation and lightweight strength through their layered design. Both types exhibit excellent durability, but solid sheets withstand direct impact better, while multiwall sheets offer extended longevity in environments demanding insulation and reduced weight.

Weight and Handling Considerations

Solid polycarbonate sheets exhibit higher density and weight compared to multiwall polycarbonate sheets, impacting ease of handling and installation. Multiwall polycarbonate sheets feature a lightweight, honeycomb structure that reduces overall weight while maintaining strength and thermal insulation. This design makes multiwall sheets easier to transport and manipulate, especially for large panels or curved applications.

Applications of Solid Polycarbonate Sheets

Solid polycarbonate sheets are widely used in applications requiring high impact resistance and optical clarity, such as safety glazing, machine guards, and greenhouse panels. These sheets provide durable protection in industrial settings, storefronts, and bullet-resistant windows due to their toughness and transparency. Their suitability for outdoor use is enhanced by UV-resistant coatings that prevent yellowing and degradation.

Applications of Multiwall Polycarbonate Sheets

Multiwall polycarbonate sheets are widely used in greenhouse glazing and skylights due to their superior thermal insulation and light diffusion properties. Their multi-layered structure enhances impact resistance and reduces heat loss, making them ideal for energy-efficient roofing and wall cladding in commercial and residential buildings. These sheets also offer UV protection, ensuring durability and long service life in outdoor applications.

Cost Analysis and Long-Term Value

Solid polycarbonate sheets typically exhibit higher initial costs due to greater material density and impact resistance, making them ideal for heavy-duty applications. Multiwall polycarbonate sheets offer cost savings upfront, attributed to their lightweight structure and enhanced thermal insulation, reducing energy expenses over time. Long-term value favors multiwall sheets in projects prioritizing energy efficiency and reduced maintenance, while solid sheets deliver superior durability for high-impact environments.

Solid Polycarbonate Sheet vs Multiwall Polycarbonate Sheet Infographic

materialdif.com

materialdif.com