Anti-static polycarbonate is specially treated to prevent the buildup of static electricity on its surface, making it ideal for applications where dust and particle attraction must be minimized. Conductive polycarbonate, on the other hand, contains conductive additives that allow it to dissipate electrical charges effectively, ensuring safety in environments prone to electrostatic discharge. Both materials enhance product performance but serve distinct purposes depending on whether static control or electrical conductivity is required.

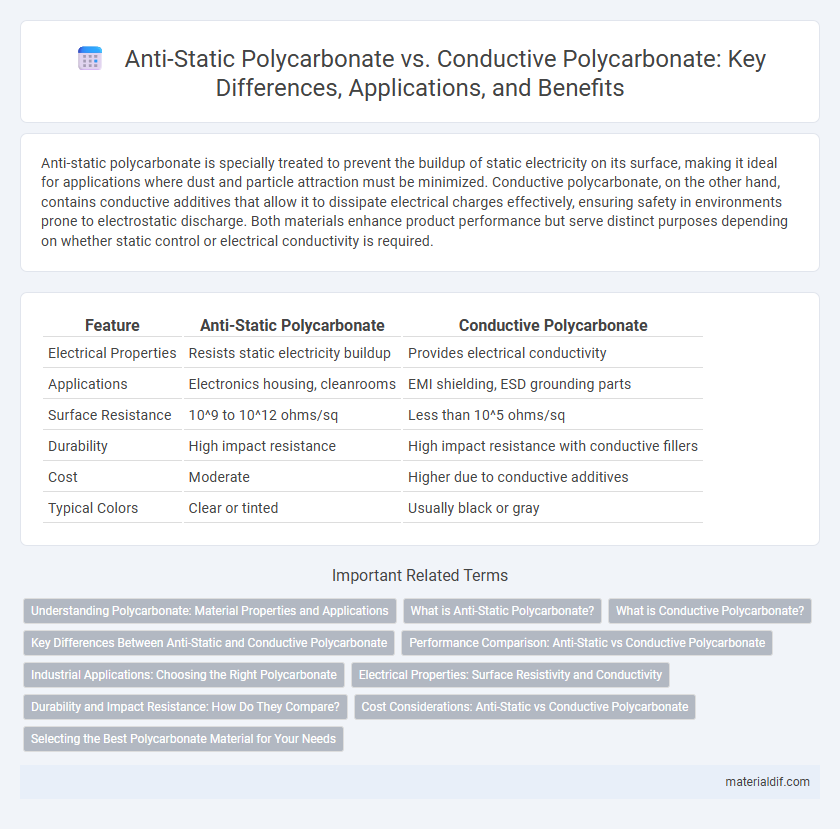

Table of Comparison

| Feature | Anti-Static Polycarbonate | Conductive Polycarbonate |

|---|---|---|

| Electrical Properties | Resists static electricity buildup | Provides electrical conductivity |

| Applications | Electronics housing, cleanrooms | EMI shielding, ESD grounding parts |

| Surface Resistance | 10^9 to 10^12 ohms/sq | Less than 10^5 ohms/sq |

| Durability | High impact resistance | High impact resistance with conductive fillers |

| Cost | Moderate | Higher due to conductive additives |

| Typical Colors | Clear or tinted | Usually black or gray |

Understanding Polycarbonate: Material Properties and Applications

Anti-static polycarbonate features surface resistivity typically between 10^9 to 10^12 ohms, reducing static charge accumulation and preventing dust attraction in electronics and cleanroom environments. Conductive polycarbonate incorporates conductive fillers, achieving resistivity below 10^5 ohms, enabling dissipation of electrical currents and protecting sensitive components from electrostatic discharge (ESD). Both variants maintain the core attributes of polycarbonate such as high impact resistance, transparency, and thermal stability, while tailoring electrical properties for specific industrial applications.

What is Anti-Static Polycarbonate?

Anti-static polycarbonate is a specialized thermoplastic material engineered to prevent the buildup of static electricity on its surface by dissipating electrical charges quickly. It features a low surface resistivity, typically between 10^9 and 10^12 ohms, which helps reduce dust attraction and static discharge in sensitive electronic environments. Commonly used in electronics housings, cleanrooms, and medical devices, anti-static polycarbonate ensures safety and reliability by minimizing electrostatic interference.

What is Conductive Polycarbonate?

Conductive polycarbonate is a type of engineered plastic that incorporates conductive fillers, such as carbon black or metal particles, to enable the dissipation of static electricity and provide electrical conductivity. This material is essential in applications requiring electrostatic discharge (ESD) protection, including electronic housings, medical devices, and packaging for sensitive components. Its unique conductivity properties distinguish it from anti-static polycarbonate, which only prevents static build-up without conducting electricity.

Key Differences Between Anti-Static and Conductive Polycarbonate

Anti-static polycarbonate reduces surface static electricity to prevent dust attraction and improve safety in sensitive environments, while conductive polycarbonate provides a continuous electrical path to ground, ensuring effective dissipation of electrical charges. Anti-static variants typically have surface resistivity ranging from 10^9 to 10^11 ohms/sq, whereas conductive grades exhibit much lower resistivity, often below 10^5 ohms/sq. The choice between anti-static and conductive polycarbonate depends on specific application requirements, such as protecting delicate electronic components or preventing electrostatic discharge hazards in high-risk areas.

Performance Comparison: Anti-Static vs Conductive Polycarbonate

Anti-static polycarbonate effectively reduces surface static charges to prevent dust attraction and electrostatic discharge, making it ideal for electronics housing and cleanroom applications. Conductive polycarbonate offers higher electrical conductivity by incorporating conductive fillers, providing reliable grounding in environments requiring continuous charge dissipation. Performance comparison reveals anti-static polycarbonate excels in low-level static control with minimal impact on optical clarity, while conductive polycarbonate delivers superior conductivity for robust electrostatic discharge protection but may reduce transparency and increase material cost.

Industrial Applications: Choosing the Right Polycarbonate

Anti-static polycarbonate prevents dust and particles from adhering to surfaces, ideal for cleanroom environments and electronic equipment housings. Conductive polycarbonate provides effective electromagnetic interference (EMI) shielding, making it suitable for enclosures in telecommunications and aerospace industries. Selecting the right polycarbonate depends on specific industrial requirements for static dissipation versus conductivity and shielding performance.

Electrical Properties: Surface Resistivity and Conductivity

Anti-static polycarbonate typically exhibits surface resistivity values ranging from 10^9 to 10^11 ohms per square, reducing static charge buildup without being fully conductive. Conductive polycarbonate, in contrast, has much lower surface resistivity, often below 10^5 ohms per square, enabling effective electrical conductivity for EMI shielding and electrostatic discharge (ESD) applications. The difference in electrical properties arises from additives: anti-static grades incorporate dissipative agents to minimize charge accumulation, while conductive grades contain conductive fillers like carbon or metal particles to allow current flow.

Durability and Impact Resistance: How Do They Compare?

Anti-static polycarbonate features a durable surface coating that reduces static buildup while maintaining high impact resistance, making it ideal for electronic housings and display panels. Conductive polycarbonate incorporates conductive fillers to provide electrical conductivity, which can sometimes slightly reduce impact strength but still offers robust durability suitable for grounding and shielding applications. Both materials exhibit excellent toughness typical of polycarbonate, but anti-static variants generally maintain superior impact resistance due to their non-compromised polymer matrix.

Cost Considerations: Anti-Static vs Conductive Polycarbonate

Anti-static polycarbonate typically incurs lower manufacturing and raw material costs compared to conductive polycarbonate, making it a more cost-effective option for applications requiring moderate electrostatic discharge protection. Conductive polycarbonate, infused with conductive fillers such as carbon black or metal fibers, demands higher production expenses due to complex compounding processes and increased material usage. Cost considerations between anti-static and conductive polycarbonate largely depend on the level of electrical conductivity needed, with conductive types offering superior performance at a premium price point.

Selecting the Best Polycarbonate Material for Your Needs

Anti-static polycarbonate prevents static charge buildup by dissipating surface charges, making it ideal for electronic housing and cleanroom environments. Conductive polycarbonate offers a higher level of electrical conductivity through the bulk material, suitable for applications requiring electromagnetic interference (EMI) shielding and grounding. Selecting the best polycarbonate depends on whether surface charge control or deeper electrical conductivity is critical for your specific industrial or commercial application.

Anti-Static Polycarbonate vs Conductive Polycarbonate Infographic

materialdif.com

materialdif.com