Impact modified polycarbonate offers enhanced toughness and superior resistance to cracking compared to standard polycarbonate, making it ideal for applications requiring higher durability. It incorporates rubber or other impact modifiers to improve flexibility without compromising transparency or strength. This modification significantly extends the material's lifespan in demanding environments while maintaining excellent optical clarity.

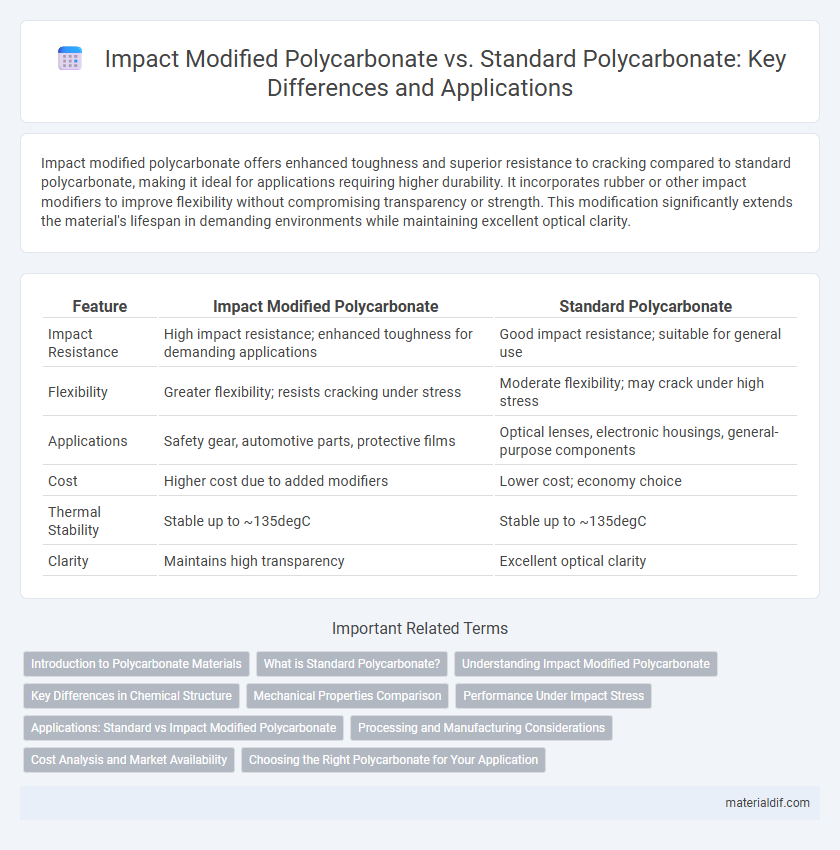

Table of Comparison

| Feature | Impact Modified Polycarbonate | Standard Polycarbonate |

|---|---|---|

| Impact Resistance | High impact resistance; enhanced toughness for demanding applications | Good impact resistance; suitable for general use |

| Flexibility | Greater flexibility; resists cracking under stress | Moderate flexibility; may crack under high stress |

| Applications | Safety gear, automotive parts, protective films | Optical lenses, electronic housings, general-purpose components |

| Cost | Higher cost due to added modifiers | Lower cost; economy choice |

| Thermal Stability | Stable up to ~135degC | Stable up to ~135degC |

| Clarity | Maintains high transparency | Excellent optical clarity |

Introduction to Polycarbonate Materials

Impact modified polycarbonate integrates rubber additives into the standard polycarbonate polymer matrix to enhance toughness and resistance to impact forces. Standard polycarbonate offers excellent clarity, strength, and thermal stability but can be brittle under high-stress conditions. The addition of impact modifiers improves durability without significantly compromising optical properties, making impact modified polycarbonate ideal for applications requiring both transparency and enhanced mechanical resilience.

What is Standard Polycarbonate?

Standard polycarbonate is a transparent thermoplastic known for its high impact resistance, optical clarity, and heat resistance, widely used in automotive, electronics, and construction industries. It offers excellent dimensional stability and is easily molded into complex shapes, making it ideal for applications requiring durability and transparency. Unlike impact-modified polycarbonate, standard polycarbonate does not contain added elastomers or modifiers, which limits its flexibility but maintains higher stiffness and strength.

Understanding Impact Modified Polycarbonate

Impact modified polycarbonate enhances standard polycarbonate by incorporating additives or blending with other polymers to significantly improve its toughness and resistance to impact fractures. This variation maintains the original material's excellent optical clarity, heat resistance, and dimensional stability while offering superior durability for demanding applications. Common uses include protective gear, automotive components, and electronic housings where enhanced impact performance is critical.

Key Differences in Chemical Structure

Impact modified polycarbonate incorporates elastomeric modifiers within the polymer matrix, enhancing toughness and resistance to fracture compared to standard polycarbonate. The presence of these impact modifiers disrupts the regular chemical structure, increasing energy absorption and reducing brittleness under stress. Standard polycarbonate features a more uniform and rigid molecular arrangement, resulting in higher stiffness but lower impact resistance.

Mechanical Properties Comparison

Impact modified polycarbonate exhibits enhanced mechanical properties compared to standard polycarbonate, including increased impact resistance and higher tensile strength, making it ideal for applications requiring durability under stress. The incorporation of elastomers in impact modified polycarbonate significantly improves its toughness and reduces brittleness without compromising thermal stability. Standard polycarbonate maintains high rigidity and optical clarity but has lower resistance to sudden impacts and cracking under dynamic loads.

Performance Under Impact Stress

Impact modified polycarbonate exhibits significantly enhanced resistance to impact stress compared to standard polycarbonate, with improved toughness and reduced brittleness under sudden forces. This modification involves blending elastomeric materials that absorb and dissipate energy, preventing crack propagation and deformation. Consequently, impact modified polycarbonate is preferred for applications requiring superior durability and reliability in high-impact environments.

Applications: Standard vs Impact Modified Polycarbonate

Impact modified polycarbonate offers enhanced toughness and resistance to cracking, making it ideal for applications requiring high durability such as protective gear, automotive parts, and electronic housings. Standard polycarbonate, while providing excellent transparency and heat resistance, is more suitable for applications like optical lenses, glazing, and general-purpose components where impact stress is minimal. Choosing between standard and impact modified polycarbonate depends on the specific mechanical and environmental demands of the application.

Processing and Manufacturing Considerations

Impact modified polycarbonate incorporates rubber or elastomeric additives to enhance toughness, requiring adjusted processing temperatures between 260degC and 300degC to prevent degradation. Standard polycarbonate processes typically operate within a narrower temperature range of 270degC to 290degC, allowing for consistent melt flow and dimensional stability. Manufacturing with impact modified grades demands slower injection speeds and optimized mold temperatures around 80degC to 120degC to minimize internal stresses and ensure uniform impact resistance.

Cost Analysis and Market Availability

Impact modified polycarbonate typically incurs higher production costs due to the incorporation of rubber modifiers that enhance toughness, resulting in a price premium of 15-25% over standard polycarbonate. Market availability for impact modified variants is somewhat more limited, with fewer suppliers and longer lead times compared to the widely stocked standard polycarbonate grades used in diverse applications. Companies must evaluate the cost-benefit ratio considering application requirements, budget constraints, and supply chain stability when selecting between these two material types.

Choosing the Right Polycarbonate for Your Application

Impact modified polycarbonate offers enhanced toughness and resistance to cracking under stress, making it ideal for applications requiring high durability, such as automotive parts and protective gear. Standard polycarbonate provides excellent clarity and strength, suitable for general-purpose uses like glazing and electronic components. Selecting the right polycarbonate depends on balancing mechanical performance requirements with environmental factors and cost considerations.

Impact Modified Polycarbonate vs Standard Polycarbonate Infographic

materialdif.com

materialdif.com