BPA-free polycarbonate offers a safer alternative to standard polycarbonate by eliminating bisphenol A, a chemical linked to potential health risks. This type of polycarbonate maintains the same durability, clarity, and impact resistance as traditional versions while ensuring safer use in food and beverage containers. Choosing BPA-free polycarbonate is crucial for reducing exposure to harmful substances without compromising the material's performance.

Table of Comparison

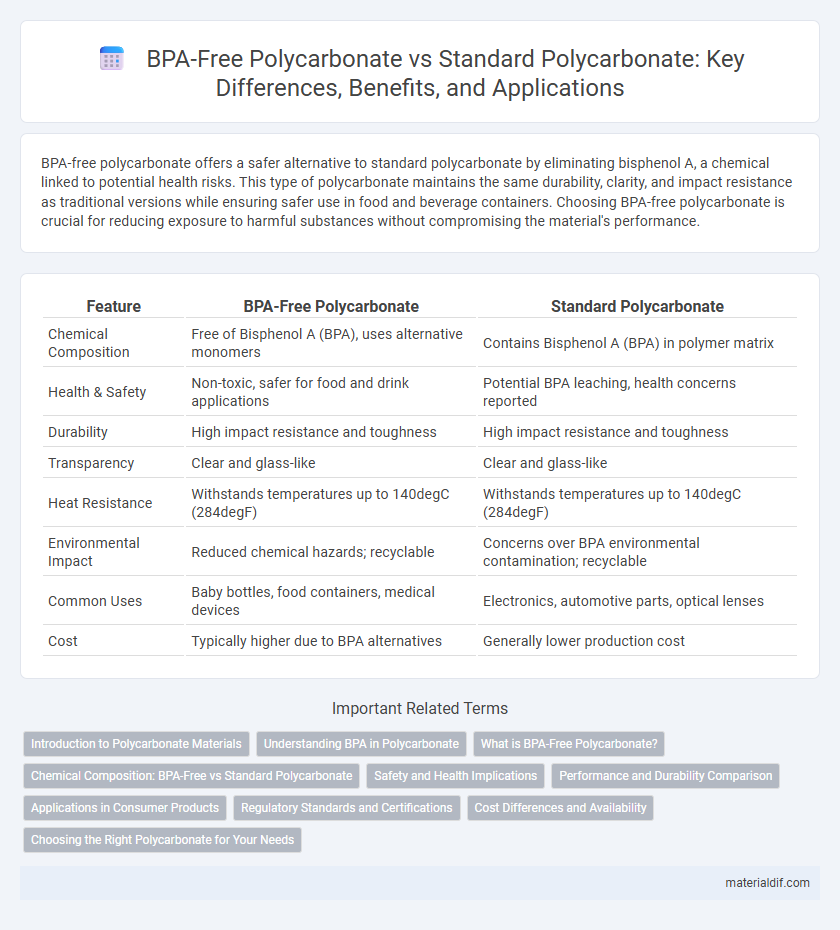

| Feature | BPA-Free Polycarbonate | Standard Polycarbonate |

|---|---|---|

| Chemical Composition | Free of Bisphenol A (BPA), uses alternative monomers | Contains Bisphenol A (BPA) in polymer matrix |

| Health & Safety | Non-toxic, safer for food and drink applications | Potential BPA leaching, health concerns reported |

| Durability | High impact resistance and toughness | High impact resistance and toughness |

| Transparency | Clear and glass-like | Clear and glass-like |

| Heat Resistance | Withstands temperatures up to 140degC (284degF) | Withstands temperatures up to 140degC (284degF) |

| Environmental Impact | Reduced chemical hazards; recyclable | Concerns over BPA environmental contamination; recyclable |

| Common Uses | Baby bottles, food containers, medical devices | Electronics, automotive parts, optical lenses |

| Cost | Typically higher due to BPA alternatives | Generally lower production cost |

Introduction to Polycarbonate Materials

Polycarbonate materials are widely used in manufacturing due to their high impact resistance, transparency, and thermal stability. BPA-free polycarbonate offers a safer alternative by eliminating bisphenol A, a chemical associated with health concerns, while maintaining similar mechanical and optical properties. Standard polycarbonate contains BPA, which can leach under certain conditions, raising environmental and health issues in applications like food containers and medical devices.

Understanding BPA in Polycarbonate

BPA-free polycarbonate is engineered without bisphenol A (BPA), a chemical that can leach from standard polycarbonate under heat or wear, raising health concerns due to its endocrine-disrupting properties. Standard polycarbonate commonly contains BPA, used in manufacturing to enhance durability and clarity but poses risks of hormone disruption when exposed to food or beverages. Understanding BPA's role in polycarbonate helps consumers choose safer alternatives that reduce exposure to potentially harmful chemicals in everyday products.

What is BPA-Free Polycarbonate?

BPA-free polycarbonate is a type of plastic manufactured without the chemical Bisphenol A (BPA), a compound commonly used in standard polycarbonate production known for potential health risks. This BPA-free alternative maintains similar durability, clarity, and heat resistance, making it suitable for applications like food containers, baby bottles, and medical devices. Regulatory agencies worldwide encourage BPA-free polycarbonate to reduce exposure to endocrine disruptors linked to various health concerns.

Chemical Composition: BPA-Free vs Standard Polycarbonate

BPA-free polycarbonate is formulated by replacing bisphenol A (BPA) with alternative compounds such as bisphenol S (BPS) or bisphenol F (BPF), resulting in a chemical structure that eliminates BPA-related health concerns. Standard polycarbonate contains BPA as a key monomer, which can leach into food or beverages under certain conditions, raising toxicity issues. The chemical modification in BPA-free polycarbonate aims to maintain durability and transparency while reducing potential endocrine-disrupting effects linked to BPA exposure.

Safety and Health Implications

BPA-free polycarbonate eliminates bisphenol A, a chemical linked to hormonal disruptions and potential health risks, making it a safer alternative for consumer products like water bottles and food containers. Standard polycarbonate contains BPA, which can leach into food and drinks, raising concerns about exposure, especially in vulnerable populations such as infants and pregnant women. Choosing BPA-free polycarbonate reduces the risk of endocrine system interference and supports long-term health safety.

Performance and Durability Comparison

BPA-free polycarbonate maintains the strong impact resistance and high optical clarity characteristic of standard polycarbonate, ensuring excellent performance in applications requiring durability. While both materials offer superior heat resistance and dimensional stability, BPA-free variants often feature enhanced chemical resistance and reduced risk of toxic leaching, making them safer for food and medical uses. The longevity of BPA-free polycarbonate matches that of traditional formulations, providing comparable scratch resistance and weatherability for outdoor or high-wear environments.

Applications in Consumer Products

BPA-free polycarbonate is widely used in consumer products such as water bottles, food containers, and baby bottles, offering a safer alternative by eliminating bisphenol A, which raises health concerns. Standard polycarbonate remains popular for its durability and clarity, commonly found in eyewear lenses, electronic casings, and automotive components. The shift towards BPA-free variants supports consumer demand for non-toxic, environmentally-friendly materials without compromising the strength and transparency essential for product performance.

Regulatory Standards and Certifications

BPA-free polycarbonate complies with stringent regulatory standards such as the FDA, EFSA, and CFIA, ensuring the absence of bisphenol A, a chemical linked to health concerns. Standard polycarbonate often falls under general FDA and EU regulations but may not meet emerging safety criteria due to BPA content. Certifications like TUV SUD for BPA-free variants highlight enhanced consumer safety and environmental compliance compared to traditional polycarbonate materials.

Cost Differences and Availability

BPA-free polycarbonate typically incurs higher production costs due to the incorporation of alternative, safer chemicals, resulting in a price premium compared to standard polycarbonate. Availability of BPA-free polycarbonate is growing rapidly as consumer demand shifts toward non-toxic materials, but it remains less widely stocked than traditional polycarbonate in many markets. Manufacturers balancing cost and safety often face trade-offs when choosing between standard polycarbonate's affordability and BPA-free variants' health compliance.

Choosing the Right Polycarbonate for Your Needs

BPA-free polycarbonate offers a safer alternative to standard polycarbonate by eliminating bisphenol A, a chemical linked to potential health risks. Choosing BPA-free polycarbonate is essential for applications involving food or drink containers to ensure non-toxicity and compliance with health regulations. Standard polycarbonate remains valuable for industrial uses requiring high durability and heat resistance but lacks the safety assurances necessary for consumer products in direct contact with consumables.

BPA-free Polycarbonate vs Standard Polycarbonate Infographic

materialdif.com

materialdif.com