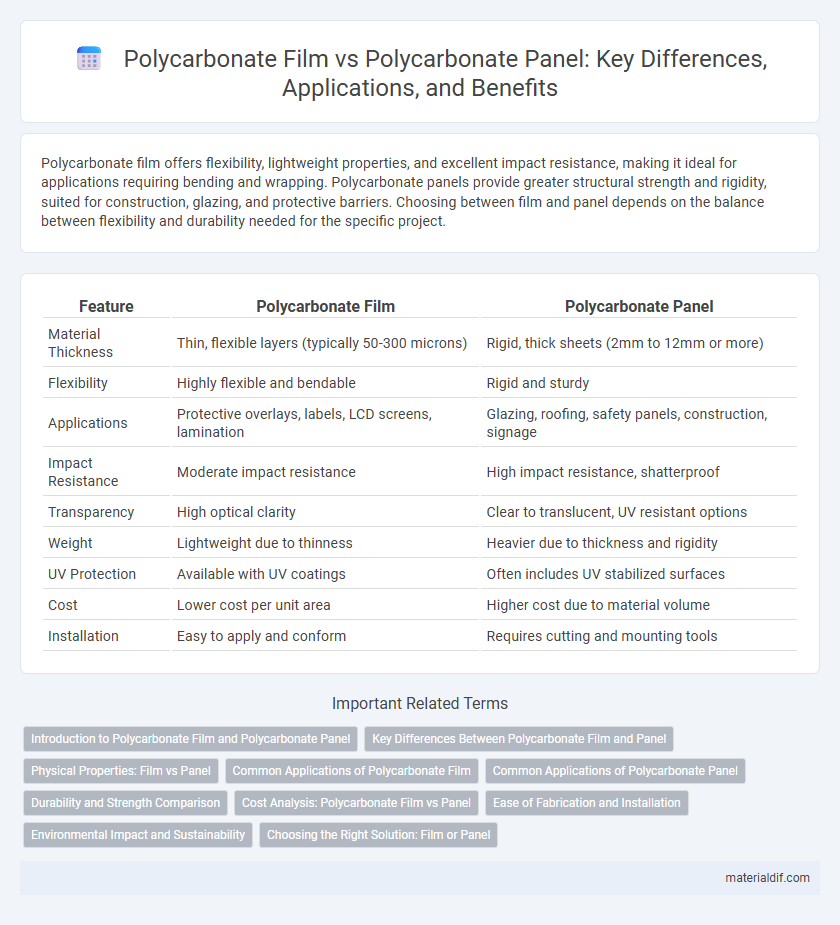

Polycarbonate film offers flexibility, lightweight properties, and excellent impact resistance, making it ideal for applications requiring bending and wrapping. Polycarbonate panels provide greater structural strength and rigidity, suited for construction, glazing, and protective barriers. Choosing between film and panel depends on the balance between flexibility and durability needed for the specific project.

Table of Comparison

| Feature | Polycarbonate Film | Polycarbonate Panel |

|---|---|---|

| Material Thickness | Thin, flexible layers (typically 50-300 microns) | Rigid, thick sheets (2mm to 12mm or more) |

| Flexibility | Highly flexible and bendable | Rigid and sturdy |

| Applications | Protective overlays, labels, LCD screens, lamination | Glazing, roofing, safety panels, construction, signage |

| Impact Resistance | Moderate impact resistance | High impact resistance, shatterproof |

| Transparency | High optical clarity | Clear to translucent, UV resistant options |

| Weight | Lightweight due to thinness | Heavier due to thickness and rigidity |

| UV Protection | Available with UV coatings | Often includes UV stabilized surfaces |

| Cost | Lower cost per unit area | Higher cost due to material volume |

| Installation | Easy to apply and conform | Requires cutting and mounting tools |

Introduction to Polycarbonate Film and Polycarbonate Panel

Polycarbonate film is a thin, flexible, and transparent material used in applications requiring durability and high impact resistance, such as protective overlays and electronic displays. Polycarbonate panels are thicker, rigid sheets designed for structural uses like glazing, roofing, and signage, offering strong thermal insulation and UV protection. Both materials leverage the inherent strength and clarity of polycarbonate, but their form factors dictate distinct functional applications across industries.

Key Differences Between Polycarbonate Film and Panel

Polycarbonate film is a thin, flexible material primarily used for protective coatings, laminations, and glazing, offering high impact resistance and optical clarity in lightweight applications. In contrast, polycarbonate panels are rigid, thick sheets designed for structural purposes such as roofing, windows, and wall cladding, providing enhanced durability, thermal insulation, and UV protection. The key differences lie in their thickness, flexibility, and typical use cases, with films suited for wrapping and overlays and panels ideal for construction and architectural applications.

Physical Properties: Film vs Panel

Polycarbonate film offers exceptional flexibility, lightweight characteristics, and high optical clarity, making it ideal for applications requiring thin, durable layers. Polycarbonate panels provide superior impact resistance, rigidity, and thermal insulation due to their thicker, solid structure, suitable for protective glazing and architectural use. The choice between film and panel depends on balancing mechanical strength versus malleability and weight requirements for specific industrial or commercial projects.

Common Applications of Polycarbonate Film

Polycarbonate film is widely used in applications requiring lightweight, flexible, and impact-resistant materials, such as protective overlays for electronic displays, automotive head-up displays, and solar control films for windows. Its thin, transparent nature allows for anti-glare and UV protection coatings, making it ideal for optical lenses and laminates in the electronics and automotive industries. Unlike rigid polycarbonate panels, the film's flexibility and durability enable its use in protective screens, touch panels, and decorative laminates.

Common Applications of Polycarbonate Panel

Polycarbonate panels are widely used in architectural glazing, skylights, and greenhouses due to their high impact resistance and excellent weather durability. These panels provide superior insulation and UV protection, making them ideal for both commercial and residential building applications. Unlike polycarbonate films, panels offer structural strength and rigidity, allowing them to serve as load-bearing components in construction projects.

Durability and Strength Comparison

Polycarbonate panels exhibit higher impact resistance and structural rigidity compared to polycarbonate films, making them ideal for applications requiring robust durability. Polycarbonate films offer flexibility and lightweight properties but generally have lower tensile strength and are more prone to surface abrasion. Both materials provide excellent UV resistance and weatherability, yet panels demonstrate superior long-term strength for demanding architectural and industrial uses.

Cost Analysis: Polycarbonate Film vs Panel

Polycarbonate film generally offers a lower initial cost compared to polycarbonate panels, making it a cost-effective choice for applications requiring flexibility and lightweight properties. However, polycarbonate panels provide enhanced durability and structural strength, which can reduce long-term maintenance and replacement expenses. A comprehensive cost analysis should consider both upfront expenses and lifecycle costs to determine the optimal material for specific project requirements.

Ease of Fabrication and Installation

Polycarbonate film offers superior ease of fabrication due to its thin, flexible nature, allowing it to be easily cut, shaped, and applied to various surfaces without specialized tools. In contrast, polycarbonate panels, while more rigid and durable, require precision cutting and fastening methods, often necessitating professional installation. The lightweight and adhesive-friendly properties of polycarbonate film make it ideal for quick, versatile applications, whereas panels provide robust structural solutions with increased installation complexity.

Environmental Impact and Sustainability

Polycarbonate film offers a thinner, lighter alternative to polycarbonate panels, reducing raw material usage and minimizing carbon footprint during production. Both materials are recyclable, but films generally require less energy to manufacture and transport, enhancing their sustainability profile. The choice between film and panel depends on application needs, with films favored for flexible, eco-friendly solutions and panels for structural durability.

Choosing the Right Solution: Film or Panel

Polycarbonate film offers lightweight flexibility and excellent UV resistance, making it ideal for applications requiring transparency and impact protection on curved surfaces or electronics. Polycarbonate panels provide greater structural strength, thermal insulation, and rigidity, suitable for construction, glazing, and roofing where durability and weather resistance are critical. Selecting between film and panel depends on factors like application demands, load-bearing requirements, and environmental exposure.

Polycarbonate Film vs Polycarbonate Panel Infographic

materialdif.com

materialdif.com