Polycarbonate PET sheet forming offers precise control over thickness and surface finish, making it ideal for applications requiring flat, rigid panels such as glazing and protective barriers. Blow molding of polycarbonate PET creates hollow, seamless shapes with excellent impact resistance, suited for containers, bottles, and complex geometries. Each method optimizes material performance differently, with sheet forming emphasizing dimensional stability and blow molding enhancing structural integrity.

Table of Comparison

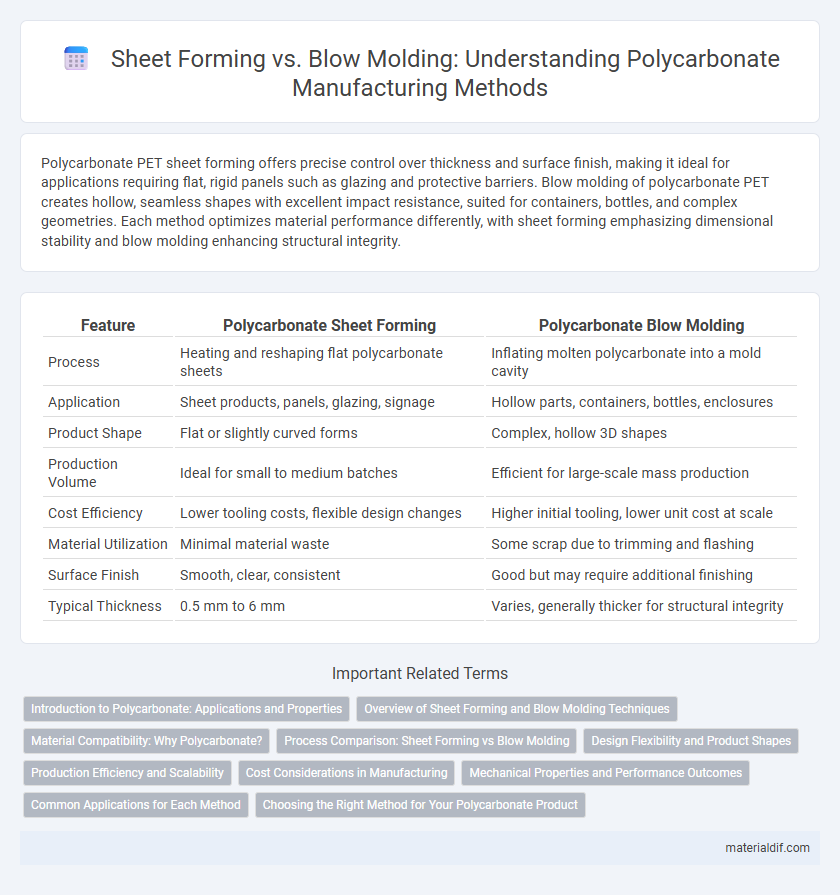

| Feature | Polycarbonate Sheet Forming | Polycarbonate Blow Molding |

|---|---|---|

| Process | Heating and reshaping flat polycarbonate sheets | Inflating molten polycarbonate into a mold cavity |

| Application | Sheet products, panels, glazing, signage | Hollow parts, containers, bottles, enclosures |

| Product Shape | Flat or slightly curved forms | Complex, hollow 3D shapes |

| Production Volume | Ideal for small to medium batches | Efficient for large-scale mass production |

| Cost Efficiency | Lower tooling costs, flexible design changes | Higher initial tooling, lower unit cost at scale |

| Material Utilization | Minimal material waste | Some scrap due to trimming and flashing |

| Surface Finish | Smooth, clear, consistent | Good but may require additional finishing |

| Typical Thickness | 0.5 mm to 6 mm | Varies, generally thicker for structural integrity |

Introduction to Polycarbonate: Applications and Properties

Polycarbonate exhibits exceptional impact resistance, transparency, and thermal stability, making it ideal for diverse applications such as automotive components, electronic housings, and protective gear. In sheet forming, polycarbonate sheets are thermoformed into precise shapes, offering uniform thickness and clarity for glazing and signage. Blow molding utilizes polycarbonate's toughness and melt strength to produce hollow objects like containers and medical equipment with complex geometries.

Overview of Sheet Forming and Blow Molding Techniques

Sheet forming of polycarbonate involves heating flat sheets and shaping them using vacuum or pressure into molds, enabling precise, smooth surfaces ideal for applications like glazing and displays. Blow molding heats polycarbonate pellets into a molten state, then inflates the material into a hollow mold to create lightweight, hollow parts such as containers and automotive components. Both techniques offer distinct advantages in terms of product complexity, structural integrity, and application suitability depending on the required manufacturing process and final product design.

Material Compatibility: Why Polycarbonate?

Polycarbonate's exceptional thermal stability and impact resistance make it highly compatible with both sheet forming and blow molding processes, ensuring durability and precise shaping. In sheet forming, polycarbonate's transparency and high strength allow for intricate thermoforming applications without compromising material integrity. Blow molding benefits from polycarbonate's excellent melt flow properties and toughness, enabling the production of lightweight, shatter-resistant containers and components.

Process Comparison: Sheet Forming vs Blow Molding

Sheet forming of polycarbonate involves thermoforming flat sheets into specific shapes using heat and pressure, providing excellent control over thickness and surface finish for applications like protective covers and panels. Blow molding shapes polycarbonate by inflating a heated parison within a mold cavity, ideal for creating hollow objects such as bottles and containers with uniform wall thickness. Sheet forming generally allows faster cycle times and superior dimensional accuracy, while blow molding excels in producing complex, hollow geometries with efficient material distribution.

Design Flexibility and Product Shapes

Sheet forming of polycarbonate offers high design flexibility, enabling precise control over thickness and intricate details for flat or slightly curved products such as panels and enclosures. Blow molding excels in producing complex, hollow shapes like bottles and containers, where seamless, uniform walls and lightweight structures are essential. Choosing between these methods depends on desired product geometry, dimensional accuracy, and manufacturing volume requirements.

Production Efficiency and Scalability

Sheet forming of polycarbonate ensures higher production efficiency with rapid cycle times and minimal material waste, making it ideal for flat or thermoformed components. Blow molding offers excellent scalability for producing hollow, complex shapes with consistent wall thickness, but typically involves longer cycle times and higher tooling costs. Choosing between these methods depends on the desired product geometry, production volume, and cost constraints in polycarbonate manufacturing.

Cost Considerations in Manufacturing

Sheet forming of polycarbonate typically incurs higher initial tooling costs due to precision dies but benefits from lower unit costs in large production runs. Blow molding often reduces material waste and tooling expenses, making it cost-effective for complex hollow shapes and smaller batches. Manufacturers must evaluate volume requirements and part complexity to determine the optimal cost strategy between sheet forming and blow molding.

Mechanical Properties and Performance Outcomes

Polycarbonate sheet forming produces flat, uniform panels with excellent impact resistance, high tensile strength, and superior optical clarity, making it ideal for applications requiring dimensional stability and rigidity. Blow molding of polycarbonate results in hollow, lightweight structures with good toughness and flexibility, suitable for container and enclosure manufacturing where complex shapes and moderate mechanical strength are needed. The choice between sheet forming and blow molding directly influences the mechanical performance, with sheet forming prioritizing stiffness and clarity, while blow molding offers enhanced design versatility and impact absorption.

Common Applications for Each Method

Polycarbonate sheet forming is commonly used in applications such as safety glazing, machine guards, and optical lenses due to its high impact resistance and excellent clarity. Blow molding of polycarbonate is frequently employed for manufacturing hollow items like bottles, containers, and automotive components where lightweight and durability are essential. Each method leverages polycarbonate's strength and versatility for distinct industrial and consumer product designs.

Choosing the Right Method for Your Polycarbonate Product

Sheet forming offers precise thickness control and superior surface finish, making it ideal for applications requiring flat or thermoformed polycarbonate parts like transparent panels and machine guards. Blow molding excels in producing hollow, complex-shaped polycarbonate items such as bottles and containers, offering efficient material distribution and reduced weight. Selecting the right method depends on the product's design complexity, structural requirements, and production volume, with sheet forming favored for flat, detailed components and blow molding suited for intricate, hollow shapes.

Sheet Forming vs Blow Molding Infographic

materialdif.com

materialdif.com