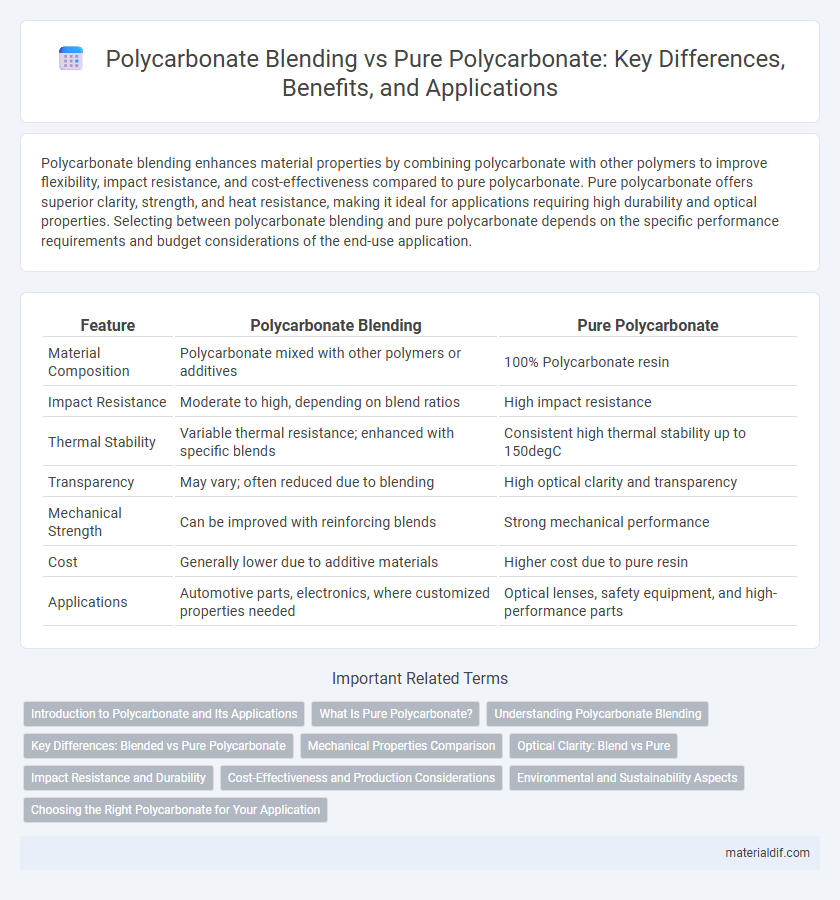

Polycarbonate blending enhances material properties by combining polycarbonate with other polymers to improve flexibility, impact resistance, and cost-effectiveness compared to pure polycarbonate. Pure polycarbonate offers superior clarity, strength, and heat resistance, making it ideal for applications requiring high durability and optical properties. Selecting between polycarbonate blending and pure polycarbonate depends on the specific performance requirements and budget considerations of the end-use application.

Table of Comparison

| Feature | Polycarbonate Blending | Pure Polycarbonate |

|---|---|---|

| Material Composition | Polycarbonate mixed with other polymers or additives | 100% Polycarbonate resin |

| Impact Resistance | Moderate to high, depending on blend ratios | High impact resistance |

| Thermal Stability | Variable thermal resistance; enhanced with specific blends | Consistent high thermal stability up to 150degC |

| Transparency | May vary; often reduced due to blending | High optical clarity and transparency |

| Mechanical Strength | Can be improved with reinforcing blends | Strong mechanical performance |

| Cost | Generally lower due to additive materials | Higher cost due to pure resin |

| Applications | Automotive parts, electronics, where customized properties needed | Optical lenses, safety equipment, and high-performance parts |

Introduction to Polycarbonate and Its Applications

Polycarbonate is a durable, high-impact thermoplastic widely used in automotive, electronics, and construction industries due to its transparency and heat resistance. Polycarbonate blending involves combining it with materials like ABS or nylon to enhance properties such as stiffness, chemical resistance, and cost-efficiency, expanding its application range. Pure polycarbonate maintains superior clarity and thermal stability, making it ideal for optical lenses, medical devices, and electrical components where material purity is critical.

What Is Pure Polycarbonate?

Pure polycarbonate is a transparent thermoplastic polymer known for its high impact resistance, optical clarity, and thermal stability. It is produced without additives or blending agents, maintaining its inherent strength, durability, and lightweight properties for applications such as eyewear lenses, automotive components, and electronic housings. Compared to polycarbonate blends, pure polycarbonate offers superior mechanical performance and consistent chemical resistance but may have limited flexibility and higher cost.

Understanding Polycarbonate Blending

Polycarbonate blending involves combining polycarbonate with other polymers or additives to enhance specific properties such as impact resistance, heat tolerance, or chemical stability, whereas pure polycarbonate offers high clarity and inherent durability. Blended polycarbonate materials can be tailored to meet industry-specific requirements in automotive, electronics, and construction applications by optimizing mechanical and thermal performance. Understanding the blending process helps manufacturers select the right formulation to balance cost, processability, and end-use functionality effectively.

Key Differences: Blended vs Pure Polycarbonate

Polycarbonate blending involves combining polycarbonate with other polymers or additives to enhance specific properties such as impact resistance, UV stability, or cost-efficiency, whereas pure polycarbonate offers superior clarity, excellent thermal resistance, and inherent toughness. Blended polycarbonate materials often exhibit tailored mechanical and chemical characteristics suitable for specialized applications, while pure polycarbonate maintains the highest level of optical transparency and durability. Choosing between blended and pure polycarbonate depends on the performance requirements and environmental factors of the intended use.

Mechanical Properties Comparison

Polycarbonate blends often exhibit enhanced mechanical properties compared to pure polycarbonate, including improved impact resistance and increased tensile strength due to synergistic effects with additives like ABS or PETG. Pure polycarbonate maintains higher clarity and thermal stability, making it preferable for applications requiring transparency and heat resistance. The blending process can tailor mechanical attributes such as stiffness and toughness, optimizing performance for specific industrial uses.

Optical Clarity: Blend vs Pure

Pure polycarbonate offers superior optical clarity with high light transmittance exceeding 88%, making it ideal for applications requiring maximum transparency and minimal distortion. Polycarbonate blends, while improving properties such as impact resistance or chemical stability, often exhibit slightly reduced clarity due to the addition of other polymers or fillers that can cause light scattering. The trade-off between enhanced mechanical characteristics and optical performance must be carefully considered for applications like eyewear lenses, automotive glazing, or electronic displays.

Impact Resistance and Durability

Polycarbonate blending enhances impact resistance by incorporating materials such as acrylic or ABS, resulting in improved toughness compared to pure polycarbonate. Pure polycarbonate offers superior optical clarity and higher heat resistance but can be more prone to stress cracking under prolonged impact. Blended polycarbonate materials balance durability and strength, making them ideal for applications requiring robust mechanical performance and enhanced longevity.

Cost-Effectiveness and Production Considerations

Polycarbonate blending reduces material costs by combining pure polycarbonate with less expensive polymers or additives, improving overall cost-effectiveness without significantly compromising mechanical properties. Production considerations include enhanced processing flexibility and reduced cycle times due to improved flow characteristics in blends compared to pure polycarbonate. Manufacturers often prefer blends to balance performance, cost, and ease of production, especially in high-volume applications.

Environmental and Sustainability Aspects

Polycarbonate blending enhances environmental sustainability by incorporating recycled polymers, reducing reliance on virgin materials and lowering carbon footprints compared to pure polycarbonate production. Blended polycarbonate often exhibits improved durability and extended lifespan, contributing to less frequent replacement and waste generation. However, pure polycarbonate's recyclability remains more straightforward, supporting closed-loop recycling systems and minimizing microplastic pollution risks.

Choosing the Right Polycarbonate for Your Application

Polycarbonate blending enhances properties such as impact resistance, chemical stability, and UV protection compared to pure polycarbonate, making it suitable for more demanding applications. Pure polycarbonate offers superior clarity and heat resistance, ideal for optical or high-temperature uses. Selecting the right polycarbonate depends on balancing mechanical performance, environmental exposure, and aesthetic requirements specific to your application.

Polycarbonate Blending vs Pure Polycarbonate Infographic

materialdif.com

materialdif.com