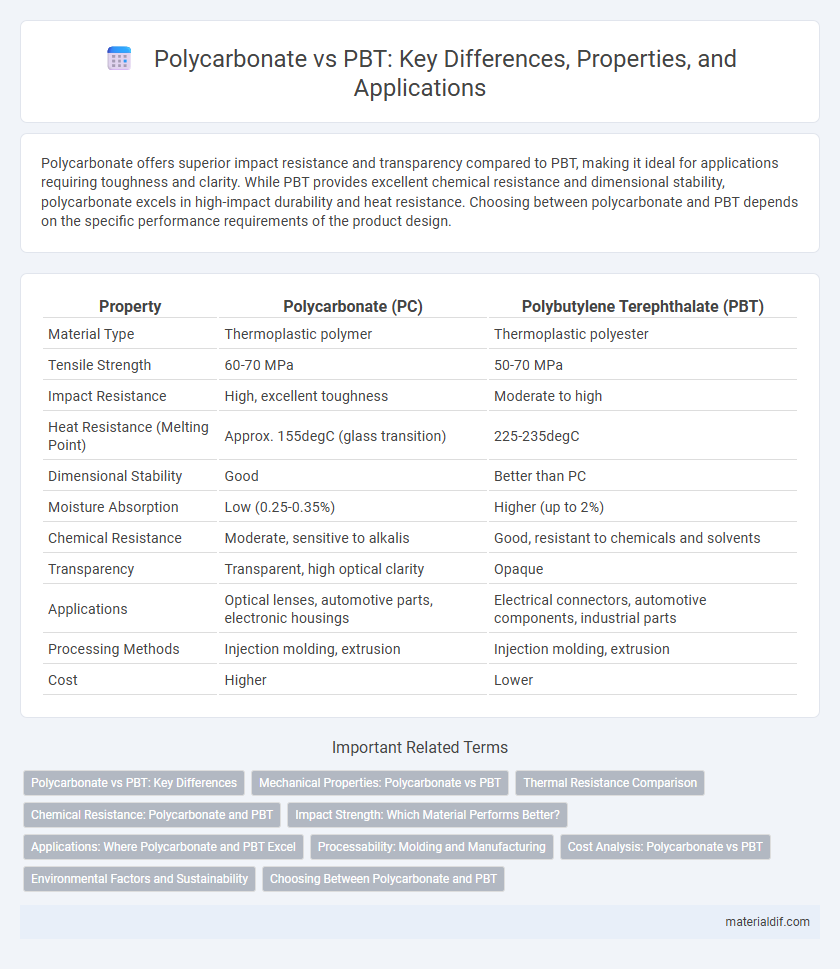

Polycarbonate offers superior impact resistance and transparency compared to PBT, making it ideal for applications requiring toughness and clarity. While PBT provides excellent chemical resistance and dimensional stability, polycarbonate excels in high-impact durability and heat resistance. Choosing between polycarbonate and PBT depends on the specific performance requirements of the product design.

Table of Comparison

| Property | Polycarbonate (PC) | Polybutylene Terephthalate (PBT) |

|---|---|---|

| Material Type | Thermoplastic polymer | Thermoplastic polyester |

| Tensile Strength | 60-70 MPa | 50-70 MPa |

| Impact Resistance | High, excellent toughness | Moderate to high |

| Heat Resistance (Melting Point) | Approx. 155degC (glass transition) | 225-235degC |

| Dimensional Stability | Good | Better than PC |

| Moisture Absorption | Low (0.25-0.35%) | Higher (up to 2%) |

| Chemical Resistance | Moderate, sensitive to alkalis | Good, resistant to chemicals and solvents |

| Transparency | Transparent, high optical clarity | Opaque |

| Applications | Optical lenses, automotive parts, electronic housings | Electrical connectors, automotive components, industrial parts |

| Processing Methods | Injection molding, extrusion | Injection molding, extrusion |

| Cost | Higher | Lower |

Polycarbonate vs PBT: Key Differences

Polycarbonate (PC) and Polybutylene Terephthalate (PBT) differ primarily in mechanical strength, thermal resistance, and chemical stability. PC exhibits higher impact resistance and transparency, making it ideal for optical applications and structural components, while PBT offers better chemical resistance and dimensional stability in high-moisture environments. These properties dictate their usage in industries such as automotive, electronics, and consumer goods, where material performance criteria vary significantly.

Mechanical Properties: Polycarbonate vs PBT

Polycarbonate exhibits higher impact strength and better toughness compared to PBT, making it ideal for applications requiring durability and resistance to sudden forces. PBT offers superior chemical resistance and dimensional stability but generally has lower impact resistance than polycarbonate. Mechanical properties such as tensile strength and elongation at break are typically higher in polycarbonate, contributing to its use in demanding engineering components.

Thermal Resistance Comparison

Polycarbonate exhibits superior thermal resistance compared to PBT, with a higher heat deflection temperature typically around 135-145degC, while PBT usually withstands temperatures up to 120-130degC. This makes polycarbonate more suitable for applications requiring prolonged exposure to elevated temperatures without deformation. Additionally, polycarbonate maintains structural integrity and mechanical properties better under thermal stress than PBT.

Chemical Resistance: Polycarbonate and PBT

Polycarbonate exhibits moderate chemical resistance, performing well against diluted acids and alkalis but showing vulnerability to strong solvents like ketones and aromatic hydrocarbons. PBT (Polybutylene Terephthalate) offers superior chemical resistance, especially against hydrocarbons, oils, and many solvents, making it more suitable for applications involving harsh chemical exposure. When comparing durability in chemical environments, PBT generally outperforms polycarbonate due to its enhanced resistance to a wider range of aggressive substances.

Impact Strength: Which Material Performs Better?

Polycarbonate exhibits superior impact strength compared to PBT, making it the preferred choice for applications requiring high durability and resistance to sudden impacts. PBT, while offering good mechanical properties, typically falls short in impact resistance under heavy stress or extreme conditions. This significant difference positions polycarbonate as the material of choice in industries such as automotive, electronics, and protective equipment where impact performance is critical.

Applications: Where Polycarbonate and PBT Excel

Polycarbonate excels in applications requiring high impact resistance and optical clarity, such as automotive components, eyewear lenses, and electronic housings. PBT is preferred in electrical and automotive industries for its excellent chemical resistance, dimensional stability, and heat resistance, making it ideal for connectors, sensor housings, and under-the-hood parts. Both materials perform well in injection molding but serve distinct markets based on mechanical strength versus thermal stability needs.

Processability: Molding and Manufacturing

Polycarbonate offers superior impact resistance and clarity, making it ideal for injection molding complex, high-precision parts with excellent surface finish. PBT excels in faster molding cycles due to lower melting temperatures and better flow characteristics, reducing production time and energy consumption. Manufacturers often select polycarbonate for applications requiring dimensional stability and toughness, while PBT is preferred for cost-effective, high-volume production of electrical and automotive components.

Cost Analysis: Polycarbonate vs PBT

Polycarbonate generally carries a higher material cost compared to PBT due to its superior impact strength and optical clarity. PBT offers a more cost-effective solution for applications requiring good mechanical properties and chemical resistance but less demand for transparency. Manufacturers often weigh the initial higher expense of polycarbonate against its performance benefits, while PBT remains favored for budget-conscious, non-transparent applications.

Environmental Factors and Sustainability

Polycarbonate boasts superior recyclability compared to Polybutylene Terephthalate (PBT), facilitating a greater reduction in environmental impact throughout its lifecycle. PBT, derived from petroleum-based sources, often exhibits lower biodegradability and higher carbon footprint during production. Polycarbonate's durability and longer service life contribute to enhanced sustainability by reducing material consumption and waste generation in industrial applications.

Choosing Between Polycarbonate and PBT

Polycarbonate offers superior impact resistance and transparency, making it the preferred choice for applications requiring toughness and clarity, such as in optical lenses and protective gear. PBT provides excellent chemical resistance and dimensional stability, ideal for electrical components and automotive parts exposed to harsh environments. Selecting between polycarbonate and PBT depends on the specific requirements for mechanical strength, thermal stability, and environmental exposure in the intended application.

Polycarbonate vs PBT Infographic

materialdif.com

materialdif.com