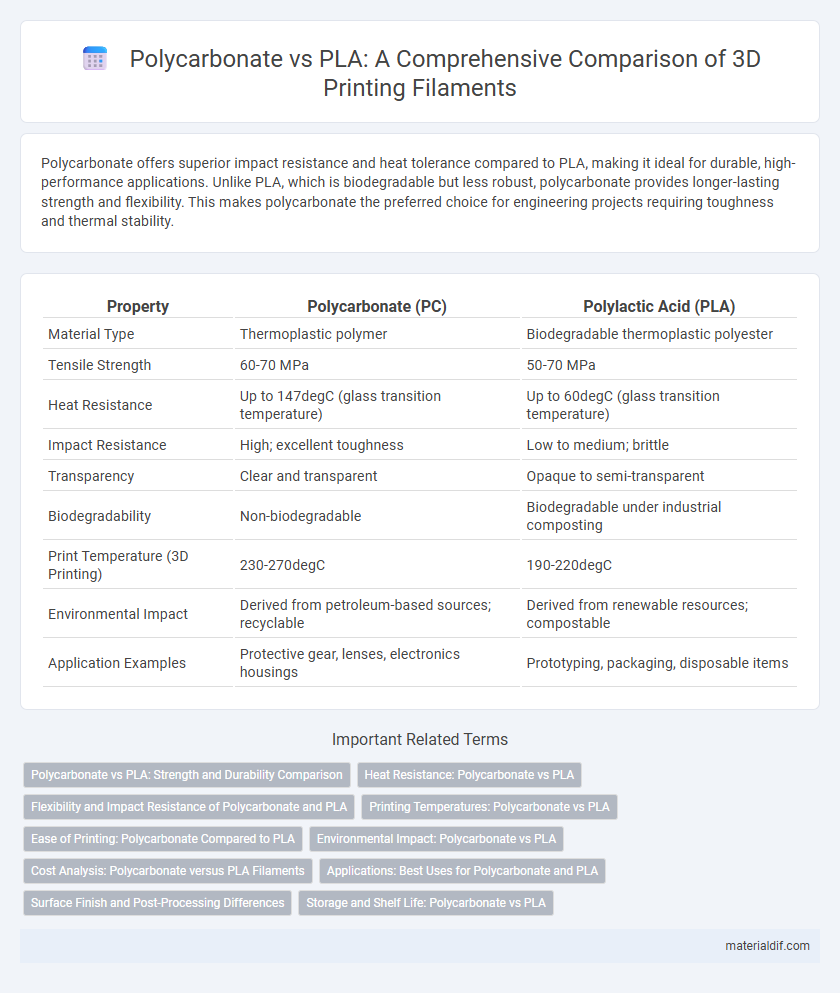

Polycarbonate offers superior impact resistance and heat tolerance compared to PLA, making it ideal for durable, high-performance applications. Unlike PLA, which is biodegradable but less robust, polycarbonate provides longer-lasting strength and flexibility. This makes polycarbonate the preferred choice for engineering projects requiring toughness and thermal stability.

Table of Comparison

| Property | Polycarbonate (PC) | Polylactic Acid (PLA) |

|---|---|---|

| Material Type | Thermoplastic polymer | Biodegradable thermoplastic polyester |

| Tensile Strength | 60-70 MPa | 50-70 MPa |

| Heat Resistance | Up to 147degC (glass transition temperature) | Up to 60degC (glass transition temperature) |

| Impact Resistance | High; excellent toughness | Low to medium; brittle |

| Transparency | Clear and transparent | Opaque to semi-transparent |

| Biodegradability | Non-biodegradable | Biodegradable under industrial composting |

| Print Temperature (3D Printing) | 230-270degC | 190-220degC |

| Environmental Impact | Derived from petroleum-based sources; recyclable | Derived from renewable resources; compostable |

| Application Examples | Protective gear, lenses, electronics housings | Prototyping, packaging, disposable items |

Polycarbonate vs PLA: Strength and Durability Comparison

Polycarbonate outperforms PLA in strength and durability, offering impact resistance up to 250 times greater and superior tensile strength, making it ideal for applications requiring toughness. Unlike PLA, which is brittle and deforms under heat above 60degC, polycarbonate withstands higher temperatures up to 150degC without losing structural integrity. This makes polycarbonate preferable for functional prototypes and end-use parts needing long-term resilience and mechanical stress resistance.

Heat Resistance: Polycarbonate vs PLA

Polycarbonate exhibits significantly higher heat resistance compared to PLA, with a heat deflection temperature around 135degC, making it suitable for high-temperature applications. PLA typically withstands heat only up to approximately 60degC before deforming, limiting its use in environments with elevated temperatures. This thermal advantage of polycarbonate ensures better durability and structural integrity in heat-exposed components.

Flexibility and Impact Resistance of Polycarbonate and PLA

Polycarbonate exhibits superior flexibility and impact resistance compared to PLA, making it ideal for applications requiring durability and toughness. PLA is more rigid and brittle, which limits its ability to absorb shocks and resist deformation under stress. The high impact resistance of polycarbonate stems from its molecular structure, enabling better performance in safety gear, automotive parts, and electronic housings.

Printing Temperatures: Polycarbonate vs PLA

Polycarbonate requires significantly higher printing temperatures, generally between 260degC and 310degC, compared to PLA which prints efficiently at 180degC to 220degC. This temperature difference affects the choice of 3D printer hardware, as polycarbonate demands an all-metal hotend and a heated bed often set around 110degC. Maintaining optimal temperature control for polycarbonate is critical to prevent warping and ensure layer adhesion, whereas PLA offers greater ease of printing with lower thermal requirements.

Ease of Printing: Polycarbonate Compared to PLA

Polycarbonate offers higher strength and heat resistance compared to PLA but requires more precise temperature control and a heated bed for successful printing. PLA is more user-friendly with lower printing temperatures and minimal warping, making it ideal for beginners. Polycarbonate's printing complexity demands advanced printers and settings to achieve optimal layer adhesion and surface finish.

Environmental Impact: Polycarbonate vs PLA

Polycarbonate exhibits higher durability and reusability compared to PLA, which breaks down more quickly but requires industrial composting to degrade effectively. PLA is derived from renewable resources like corn starch, offering a lower carbon footprint during production, whereas polycarbonate relies on petroleum-based raw materials, contributing to greater environmental pollution. However, the long lifespan of polycarbonate reduces waste frequency, while PLA's biodegradability mitigates landfill accumulation but may produce methane if improperly managed.

Cost Analysis: Polycarbonate versus PLA Filaments

Polycarbonate filaments typically cost between $40 to $80 per kilogram, reflecting their superior impact resistance and heat tolerance compared to PLA, which ranges from $20 to $40 per kilogram and is valued for its biodegradability and ease of printing. The higher material cost of polycarbonate is offset by its durability and thermal stability, making it ideal for industrial applications requiring long-term performance under mechanical stress. In contrast, PLA's affordability and eco-friendly properties make it preferable for prototyping and low-stress, consumer-grade 3D printing projects.

Applications: Best Uses for Polycarbonate and PLA

Polycarbonate is ideal for high-impact applications such as automotive components, protective gear, and electronic housings due to its superior durability and heat resistance. PLA, being biodegradable and easy to print, is best suited for prototyping, packaging, and disposable items in the food industry. Choosing between polycarbonate and PLA depends on the need for strength and temperature stability versus environmental sustainability and ease of fabrication.

Surface Finish and Post-Processing Differences

Polycarbonate offers a smooth, glossy surface finish that is more resistant to scratches and heat compared to PLA, which tends to have a matte or slightly rough texture. Post-processing polycarbonate often requires higher temperatures for sanding or polishing to maintain its clarity and durability, whereas PLA can be easily sanded, painted, or smoothed with solvents like acetone. The superior strength and thermal resistance of polycarbonate make its surface finish and post-processing more demanding but result in a more robust and visually appealing final product.

Storage and Shelf Life: Polycarbonate vs PLA

Polycarbonate offers superior storage stability compared to PLA due to its high resistance to moisture and thermal degradation, extending its shelf life significantly. PLA, being biodegradable and more prone to hydrolysis, requires more controlled storage environments with low humidity and stable temperatures to maintain integrity. Consequently, polycarbonate is preferred for long-term storage applications where durability and consistent performance over time are critical.

Polycarbonate vs PLA Infographic

materialdif.com

materialdif.com