Polycarbonate textured finish offers enhanced grip and reduced visibility of fingerprints compared to the smooth, reflective surface of polycarbonate gloss finish. The textured finish is ideal for applications requiring durability and a matte appearance, while gloss finish provides a sleek, shiny look suitable for aesthetic-focused products. Choosing between these finishes depends on the balance between functionality and visual appeal needed for specific projects.

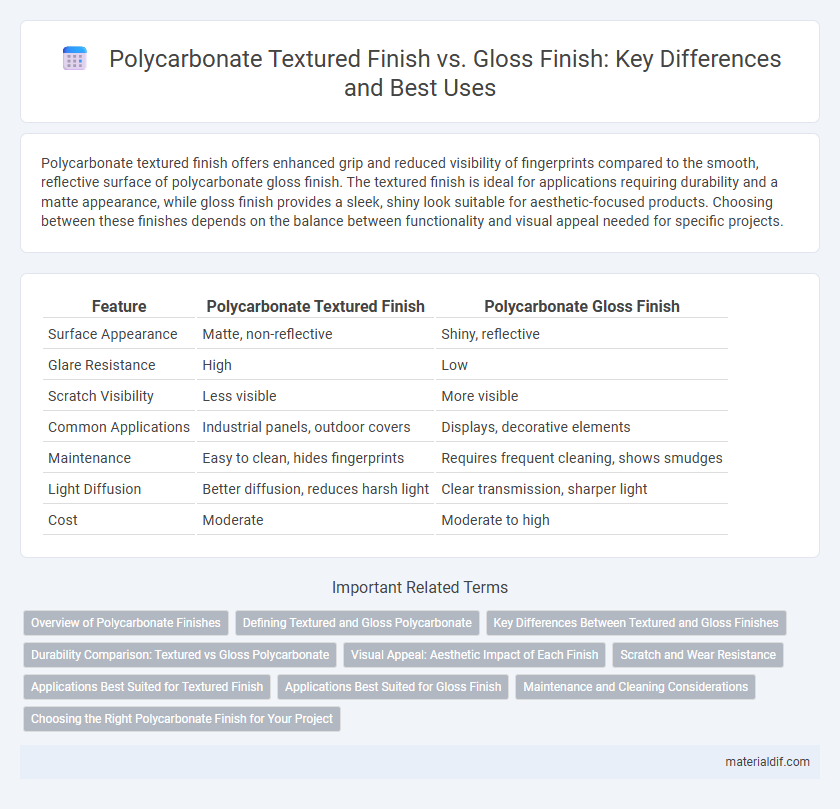

Table of Comparison

| Feature | Polycarbonate Textured Finish | Polycarbonate Gloss Finish |

|---|---|---|

| Surface Appearance | Matte, non-reflective | Shiny, reflective |

| Glare Resistance | High | Low |

| Scratch Visibility | Less visible | More visible |

| Common Applications | Industrial panels, outdoor covers | Displays, decorative elements |

| Maintenance | Easy to clean, hides fingerprints | Requires frequent cleaning, shows smudges |

| Light Diffusion | Better diffusion, reduces harsh light | Clear transmission, sharper light |

| Cost | Moderate | Moderate to high |

Overview of Polycarbonate Finishes

Polycarbonate textured finishes provide enhanced scratch resistance and diffuse light to reduce glare, making them ideal for applications requiring durability and privacy. In contrast, polycarbonate gloss finishes offer a smooth, reflective surface that enhances clarity and aesthetic appeal, commonly used in displays and signage. Both finishes maintain the inherent strength and impact resistance of polycarbonate, with choices driven by functional and visual requirements.

Defining Textured and Gloss Polycarbonate

Polycarbonate textured finish features a surface with slight irregularities or patterns that enhance grip, reduce glare, and hide scratches, making it ideal for industrial and outdoor applications. In contrast, polycarbonate gloss finish offers a smooth, shiny surface that maximizes light reflection and clarity, commonly used for aesthetic purposes such as displays and protective covers. Both finishes leverage polycarbonate's inherent durability and impact resistance but serve distinct functional and visual needs.

Key Differences Between Textured and Gloss Finishes

Polycarbonate textured finish offers enhanced scratch resistance and reduced glare compared to polycarbonate gloss finish, which provides a smooth, shiny surface with higher reflectivity. Textured finishes improve grip and hide fingerprints, making them ideal for high-contact applications, while gloss finishes emphasize aesthetic appeal with a sleek, polished look. The choice between textured and gloss polycarbonate finishes depends on the desired balance between durability and visual effect.

Durability Comparison: Textured vs Gloss Polycarbonate

Polycarbonate textured finishes exhibit superior scratch resistance and conceal surface imperfections better than gloss finishes, enhancing long-term durability in high-traffic applications. Gloss polycarbonate surfaces, while visually striking with enhanced clarity and shine, are more prone to visible scratches and wear over time. Both finishes maintain the inherent impact resistance of polycarbonate, but textured options provide added resilience against abrasion and everyday wear.

Visual Appeal: Aesthetic Impact of Each Finish

Polycarbonate textured finishes scatter light to create a matte appearance, reducing glare and hiding fingerprints, which offers a subtle, sophisticated look ideal for modern architectural applications. In contrast, polycarbonate gloss finishes enhance color vibrancy and reflectivity, delivering a sleek, high-shine surface that accentuates design details and adds a dynamic visual impact. The choice between textured and gloss finishes significantly influences the overall aesthetic, balancing between understated elegance and bold, polished presentation.

Scratch and Wear Resistance

Polycarbonate textured finishes offer superior scratch and wear resistance compared to polycarbonate gloss finishes due to their matte surface that effectively masks minor abrasions and reduces visible wear over time. Gloss finishes, while visually appealing with high shine and clarity, are more prone to visible scratches and surface damage, requiring more frequent maintenance to retain their pristine appearance. Selecting a textured finish enhances durability in high-use environments, extending the lifespan of polycarbonate components exposed to abrasive conditions.

Applications Best Suited for Textured Finish

Polycarbonate textured finish is ideal for applications requiring reduced glare and enhanced surface grip, such as safety helmet visors, automotive interior panels, and protective eyewear lenses. This finish helps conceal fingerprints, scratches, and surface imperfections, making it suitable for high-contact surfaces in industrial and consumer products. Textured polycarbonate also improves light diffusion, benefiting architectural glazing and outdoor signage where visual comfort and durability are crucial.

Applications Best Suited for Gloss Finish

Polycarbonate gloss finish is best suited for applications requiring high clarity and a sleek, shiny appearance, such as automotive headlight covers, electronic device casings, and optical lenses. The smooth, reflective surface enhances visual appeal while maintaining excellent impact resistance and weatherability. This finish is ideal for consumer products and architectural glazing where aesthetic quality and durability are essential.

Maintenance and Cleaning Considerations

Polycarbonate textured finishes resist fingerprints and minor scratches, reducing the frequency of cleaning compared to gloss finishes, which show smudges and dust more prominently. Cleaning textured polycarbonate requires gentle brushing or mild detergents to avoid damaging the surface texture, while gloss finishes benefit from soft cloths and non-abrasive cleaners to maintain shine. Selecting the appropriate finish depends on the maintenance environment, with textured surfaces preferred in high-traffic or outdoor applications for easier upkeep.

Choosing the Right Polycarbonate Finish for Your Project

Polycarbonate textured finish offers enhanced scratch resistance and reduced glare, making it ideal for outdoor applications where durability and visibility are critical. In contrast, polycarbonate gloss finish provides a sleek, reflective surface that enhances aesthetic appeal and light transmission, suitable for indoor projects or decorative uses. Selecting the right polycarbonate finish depends on the project's functional demands and environmental conditions, balancing durability with visual requirements.

Polycarbonate Textured Finish vs Polycarbonate Gloss Finish Infographic

materialdif.com

materialdif.com