BPA-free polycarbonate offers a safer alternative to traditional polycarbonate by eliminating bisphenol A, a chemical linked to health concerns. This innovation maintains the durability and clarity of conventional polycarbonate while ensuring non-toxicity in food and beverage containers. Consumers increasingly prefer BPA-free options for safer, long-lasting polycarbonate products.

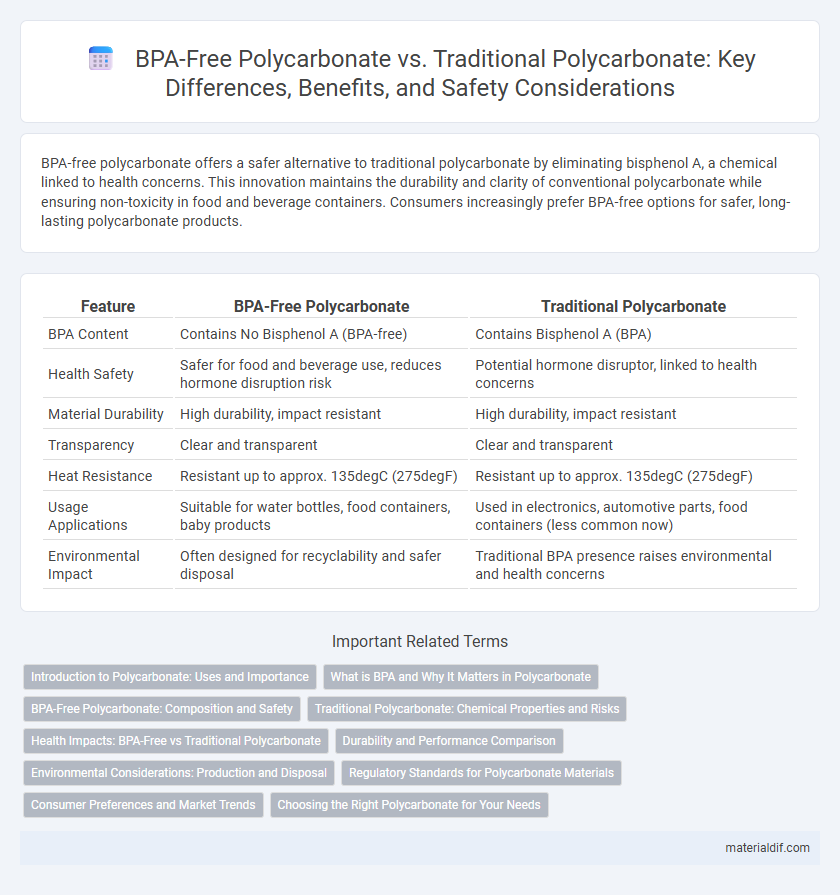

Table of Comparison

| Feature | BPA-Free Polycarbonate | Traditional Polycarbonate |

|---|---|---|

| BPA Content | Contains No Bisphenol A (BPA-free) | Contains Bisphenol A (BPA) |

| Health Safety | Safer for food and beverage use, reduces hormone disruption risk | Potential hormone disruptor, linked to health concerns |

| Material Durability | High durability, impact resistant | High durability, impact resistant |

| Transparency | Clear and transparent | Clear and transparent |

| Heat Resistance | Resistant up to approx. 135degC (275degF) | Resistant up to approx. 135degC (275degF) |

| Usage Applications | Suitable for water bottles, food containers, baby products | Used in electronics, automotive parts, food containers (less common now) |

| Environmental Impact | Often designed for recyclability and safer disposal | Traditional BPA presence raises environmental and health concerns |

Introduction to Polycarbonate: Uses and Importance

Polycarbonate is a versatile thermoplastic extensively used in industries such as automotive, electronics, and medical devices due to its high impact resistance, optical clarity, and thermal stability. BPA-free polycarbonate variants have emerged to address health concerns associated with bisphenol A, maintaining the material's durability and transparency while eliminating harmful chemical leaching. This innovation enhances consumer safety without compromising the essential applications of traditional polycarbonate in manufacturing and product design.

What is BPA and Why It Matters in Polycarbonate

BPA, or Bisphenol A, is a chemical used in the production of traditional polycarbonate plastics and epoxy resins, known for its potential endocrine-disrupting effects. BPA-Free polycarbonate is engineered to eliminate this compound, reducing health risks associated with hormone interference and chemical leaching. Choosing BPA-Free polycarbonate prioritizes consumer safety while maintaining the material's durability and clarity.

BPA-Free Polycarbonate: Composition and Safety

BPA-free polycarbonate is composed of alternative monomers replacing bisphenol A, ensuring reduced health risks linked to endocrine disruption. This material maintains high impact resistance and transparency similar to traditional polycarbonate, making it suitable for consumer products like water bottles and food containers. Regulatory agencies recognize BPA-free polycarbonate as a safer option due to its minimized leaching of harmful chemicals under typical usage conditions.

Traditional Polycarbonate: Chemical Properties and Risks

Traditional polycarbonate is composed of bisphenol A (BPA), which imparts high impact resistance and clarity but raises significant health concerns due to potential BPA leaching. The chemical structure of traditional polycarbonate involves the presence of BPA monomers that can migrate into food or beverages under heat or acidic conditions, posing endocrine disruption risks. Regulatory scrutiny highlights the need for caution in using traditional polycarbonate in food contact applications due to these chemical and toxicological hazards.

Health Impacts: BPA-Free vs Traditional Polycarbonate

BPA-free polycarbonate eliminates bisphenol A, a chemical linked to hormone disruption and potential health risks found in traditional polycarbonate plastics. Traditional polycarbonate can leach BPA into food and beverages, especially when heated, raising concerns over endocrine system interference and increased risk of certain cancers. BPA-free alternatives use safer compounds, significantly reducing exposure to harmful chemicals and promoting better long-term health outcomes.

Durability and Performance Comparison

BPA-free polycarbonate maintains comparable durability to traditional polycarbonate, offering resistance to impact, heat, and chemicals ideal for long-term use in various applications. This safer alternative eliminates bisphenol A without compromising performance characteristics such as UV resistance and optical clarity. Its enhanced safety profile paired with robust mechanical properties positions BPA-free polycarbonate as a leading material in medical devices, food containers, and consumer electronics.

Environmental Considerations: Production and Disposal

BPA-free polycarbonate reduces the release of bisphenol A, a harmful chemical associated with traditional polycarbonate production that impacts both human health and ecosystems. Production of BPA-free variants often involves alternative monomers designed to minimize toxic byproducts and lower environmental pollution. Disposal of BPA-free polycarbonate poses fewer risks of chemical leaching into soil and water, promoting safer biodegradation or recycling compared to traditional BPA-based plastics.

Regulatory Standards for Polycarbonate Materials

BPA-free polycarbonate complies with stringent regulatory standards such as the FDA's Food Contact Substance Notifications and the European Union's REACH regulations, ensuring reduced health risks from bisphenol A exposure. Traditional polycarbonate often contains BPA, which faces increasing restrictions globally due to its endocrine-disrupting potential, particularly in products intended for food and beverage use. Regulatory agencies emphasize testing and certification to guarantee the safety and compliance of polycarbonate materials used in consumer goods.

Consumer Preferences and Market Trends

BPA-free polycarbonate is increasingly favored by health-conscious consumers due to concerns over bisphenol A's potential endocrine-disrupting effects, driving a significant shift in market demand. Market trends show a steady increase in production and availability of BPA-free alternatives, reflecting manufacturers' response to regulatory pressures and consumer preferences. This shift influences innovation in polycarbonate formulations, promoting safer and more sustainable plastic products in sectors like food packaging and baby bottles.

Choosing the Right Polycarbonate for Your Needs

BPA-free polycarbonate offers a safer alternative to traditional polycarbonate by eliminating bisphenol A, reducing health risks associated with chemical leaching. When choosing the right polycarbonate, consider factors such as application safety standards, durability requirements, and environmental impact. BPA-free options maintain similar strength and clarity while ensuring compliance with health regulations in food and beverage containers or medical devices.

BPA-Free Polycarbonate vs Traditional Polycarbonate Infographic

materialdif.com

materialdif.com