Polycarbonate offers exceptional impact resistance and optical clarity, making it ideal for applications requiring transparency and toughness. Delrin, or acetal resin, excels in dimensional stability, low friction, and chemical resistance, better suited for precise mechanical parts. Choosing between polycarbonate and Delrin depends on whether clarity and impact strength or mechanical precision and wear resistance are the primary requirements.

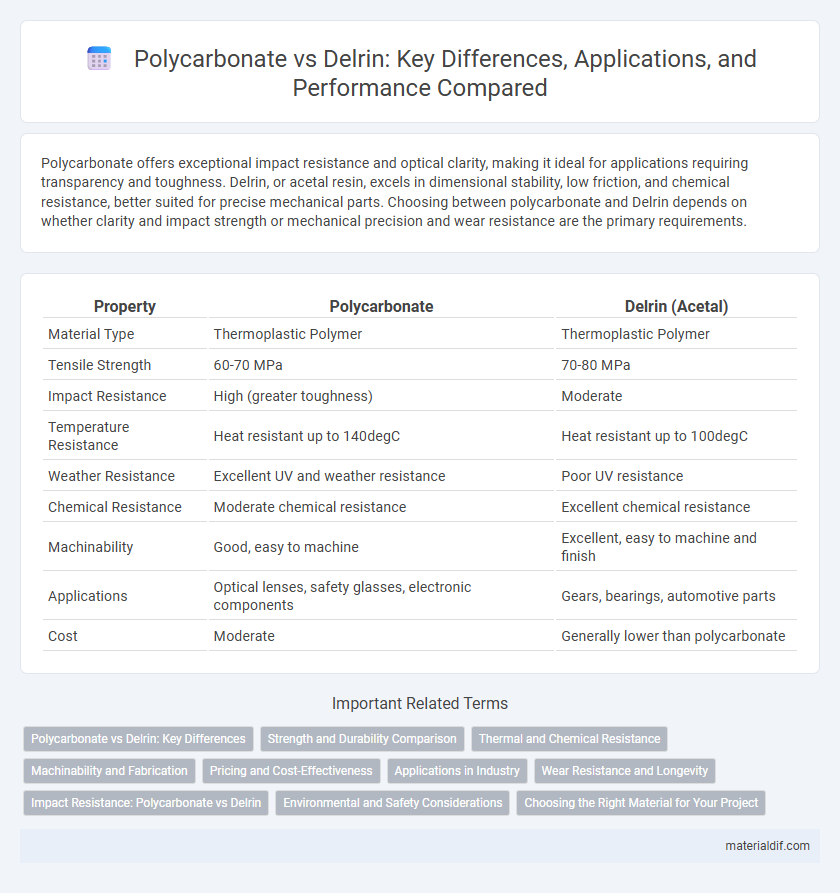

Table of Comparison

| Property | Polycarbonate | Delrin (Acetal) |

|---|---|---|

| Material Type | Thermoplastic Polymer | Thermoplastic Polymer |

| Tensile Strength | 60-70 MPa | 70-80 MPa |

| Impact Resistance | High (greater toughness) | Moderate |

| Temperature Resistance | Heat resistant up to 140degC | Heat resistant up to 100degC |

| Weather Resistance | Excellent UV and weather resistance | Poor UV resistance |

| Chemical Resistance | Moderate chemical resistance | Excellent chemical resistance |

| Machinability | Good, easy to machine | Excellent, easy to machine and finish |

| Applications | Optical lenses, safety glasses, electronic components | Gears, bearings, automotive parts |

| Cost | Moderate | Generally lower than polycarbonate |

Polycarbonate vs Delrin: Key Differences

Polycarbonate offers superior impact resistance and optical clarity compared to Delrin, which is primarily valued for its excellent wear resistance and dimensional stability. Polycarbonate is commonly used in applications requiring transparency and high toughness, such as safety glasses and electronic components, while Delrin excels in mechanical parts like gears and bearings due to its low friction and high stiffness. The thermal resistance of Polycarbonate generally exceeds that of Delrin, making it more suitable for environments with fluctuating temperatures.

Strength and Durability Comparison

Polycarbonate exhibits exceptional impact resistance with a tensile strength of approximately 9,500 psi, making it highly durable under heavy stress and impact. Delrin, or acetal resin, has a tensile strength around 10,500 psi but offers superior stiffness and wear resistance, ideal for precision machined parts. While polycarbonate excels in toughness and impact absorption, Delrin provides better dimensional stability and resistance to fatigue over prolonged mechanical use.

Thermal and Chemical Resistance

Polycarbonate offers superior thermal resistance with a heat deflection temperature around 130degC, making it suitable for high-temperature applications. Delrin, or acetal resin, has a lower heat resistance, typically around 90degC, but excels in chemical resistance against solvents and fuels. Polycarbonate is preferable in environments requiring higher thermal endurance, whereas Delrin is better for exposure to aggressive chemicals.

Machinability and Fabrication

Polycarbonate offers excellent machinability with high impact resistance and thermal stability, allowing for precision fabrication in complex shapes without cracking or chipping. Delrin, or acetal resin, provides superior dimensional stability and low friction, which makes it ideal for parts requiring tight tolerances and smooth surface finishes during machining. Both materials excel in fabrication, but polycarbonate's transparency and toughness make it preferable for applications needing visual inspection, while Delrin's rigidity suits mechanical components.

Pricing and Cost-Effectiveness

Polycarbonate generally costs more than Delrin but offers superior impact resistance and optical clarity, making it cost-effective for applications requiring durability and transparency. Delrin, a type of acetal resin, is more affordable and excels in mechanical strength, wear resistance, and low friction, providing better value for precision parts and engineering applications. Choosing between Polycarbonate and Delrin depends on balancing material performance with budget constraints, where polycarbonate may justify higher cost through enhanced properties.

Applications in Industry

Polycarbonate is widely used in industries requiring high impact resistance and optical clarity, such as automotive headlamp lenses, electronic displays, and safety shields. Delrin, a type of acetal resin, excels in mechanical applications demanding exceptional stiffness, low friction, and dimensional stability, making it ideal for gears, bearings, and precision-machined components. The choice between polycarbonate and Delrin depends on specific industry needs for strength, wear resistance, and environmental exposure.

Wear Resistance and Longevity

Polycarbonate exhibits moderate wear resistance and maintains clarity under stress, making it suitable for applications requiring impact resistance and transparency. Delrin, an acetal resin, offers superior wear resistance and low friction properties, which contribute to its longer lifespan in mechanical components subjected to continuous motion. For durability and longevity in wear-intensive environments, Delrin typically outperforms polycarbonate due to its enhanced abrasion resistance and dimensional stability.

Impact Resistance: Polycarbonate vs Delrin

Polycarbonate exhibits superior impact resistance compared to Delrin, effectively absorbing high-energy impacts without cracking or breaking. Delrin, while strong and rigid, is more prone to brittle failure under sudden impact stresses. The enhanced toughness of polycarbonate makes it ideal for applications requiring durable, impact-resistant materials.

Environmental and Safety Considerations

Polycarbonate offers superior impact resistance and transparency, making it favorable in applications requiring safety and visibility, while Delrin, an acetal resin, excels in mechanical strength but lacks optical clarity. Polycarbonate is more prone to environmental stress cracking and UV degradation, requiring protective coatings to enhance outdoor durability, whereas Delrin is more chemically resistant and stable under prolonged environmental exposure. Both materials are recyclable, but polycarbonate's potential BPA release during processing raises additional environmental and health considerations compared to Delrin's lower toxicity profile.

Choosing the Right Material for Your Project

Polycarbonate offers exceptional impact resistance and clarity, making it ideal for applications requiring toughness and transparency, while Delrin excels with superior dimensional stability and low friction, perfect for precision mechanical parts. Consider polycarbonate's high tensile strength and heat resistance when durability under stress and temperature is crucial. Select Delrin for wear-resistant components demanding consistent performance and minimal deformation over time.

Polycarbonate vs Delrin Infographic

materialdif.com

materialdif.com