Lexan and Makrolon are two leading brands of polycarbonate known for their exceptional impact resistance and optical clarity. Lexan, manufactured by Sabic, often excels in UV resistance and thermal stability, making it ideal for outdoor applications, while Makrolon, produced by Covestro, is favored for its consistent quality and versatility in various industrial and automotive uses. Both materials offer lightweight strength and durability, but the choice depends on specific project requirements such as environmental exposure and mechanical demands.

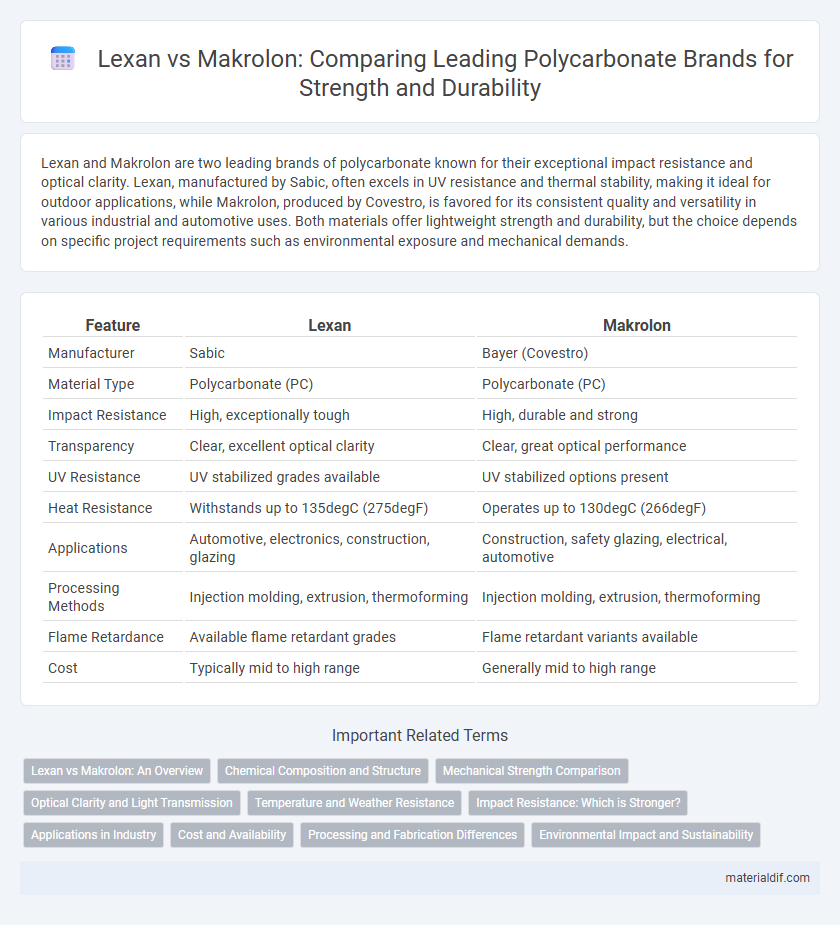

Table of Comparison

| Feature | Lexan | Makrolon |

|---|---|---|

| Manufacturer | Sabic | Bayer (Covestro) |

| Material Type | Polycarbonate (PC) | Polycarbonate (PC) |

| Impact Resistance | High, exceptionally tough | High, durable and strong |

| Transparency | Clear, excellent optical clarity | Clear, great optical performance |

| UV Resistance | UV stabilized grades available | UV stabilized options present |

| Heat Resistance | Withstands up to 135degC (275degF) | Operates up to 130degC (266degF) |

| Applications | Automotive, electronics, construction, glazing | Construction, safety glazing, electrical, automotive |

| Processing Methods | Injection molding, extrusion, thermoforming | Injection molding, extrusion, thermoforming |

| Flame Retardance | Available flame retardant grades | Flame retardant variants available |

| Cost | Typically mid to high range | Generally mid to high range |

Lexan vs Makrolon: An Overview

Lexan and Makrolon are leading brands of polycarbonate known for their exceptional impact resistance and optical clarity, widely used in automotive, construction, and electronics industries. Lexan, produced by SABIC, offers superior weatherability and flame retardance, while Makrolon, manufactured by Covestro, is renowned for its excellent UV resistance and thermal stability. Both materials provide lightweight alternatives to glass, but selection depends on specific application requirements such as durability, transparency, and environmental exposure.

Chemical Composition and Structure

Lexan and Makrolon are both types of polycarbonate known for their high impact resistance and transparency, yet they differ subtly in chemical composition and molecular structure. Lexan, produced by SABIC, typically contains bisphenol A-based carbonate units, resulting in a slightly higher molecular weight and greater thermal stability. Makrolon, manufactured by Covestro, features a similar bisphenol A backbone but incorporates specific additives and polymerization techniques to enhance UV resistance and surface hardness.

Mechanical Strength Comparison

Lexan and Makrolon are both premium polycarbonate brands known for exceptional mechanical strength, with Lexan often favored for impact resistance and Makrolon for tensile strength. Lexan exhibits high impact toughness, making it ideal for protective gear and bulletproof applications, while Makrolon demonstrates superior stiffness and load-bearing capacity suitable for structural components. Mechanical testing typically shows Lexan achieving impact strength values above 900 J/m, whereas Makrolon's tensile strength ranges from 60 to 70 MPa, emphasizing different strengths tailored to specific industrial uses.

Optical Clarity and Light Transmission

Lexan exhibits superior optical clarity with light transmission rates reaching up to 89%, making it ideal for applications requiring high visibility and minimal distortion. Makrolon also maintains excellent transparency with light transmittance around 88%, providing reliable clarity in various industrial uses. Both polycarbonates resist yellowing over time, but Lexan's proprietary formulation often results in enhanced clarity retention under prolonged UV exposure.

Temperature and Weather Resistance

Lexan and Makrolon are high-performance polycarbonate brands known for exceptional temperature and weather resistance. Lexan can withstand continuous exposure to temperatures up to 120degC, while Makrolon maintains structural integrity at temperatures up to 130degC. Both materials exhibit superior UV resistance and impact strength, making them ideal for outdoor applications exposed to harsh weather conditions.

Impact Resistance: Which is Stronger?

Lexan polycarbonate, produced by SABIC, offers superior impact resistance with a higher notched Izod value compared to Makrolon by Covestro, making it ideal for applications demanding robust durability. Lexan typically withstands impacts up to 900 Joules per meter, whereas Makrolon provides slightly lower resistance but excels in thermal stability. The enhanced molecular structure of Lexan contributes to its exceptional toughness, ensuring better performance in high-impact environments.

Applications in Industry

Lexan and Makrolon are two leading polycarbonate brands widely used across various industries for their durability and clarity. Lexan polycarbonate is favored in automotive components, electronic devices, and protective gear due to its excellent impact resistance and thermal stability. Makrolon polycarbonate is commonly utilized in construction, medical equipment, and optical lenses, offering superior UV resistance and chemical stability tailored for demanding industrial applications.

Cost and Availability

Lexan and Makrolon polycarbonate sheets differ notably in cost and availability, with Lexan often priced slightly higher due to its brand premium and advanced impact resistance features. Makrolon, widely produced by Covestro, benefits from extensive global distribution networks, making it more readily available in bulk for industrial applications. Both materials are cost-effective compared to alternatives like acrylic, but Makrolon's consistent supply chain tends to offer better pricing flexibility for large-scale projects.

Processing and Fabrication Differences

Lexan, manufactured by SABIC, offers superior impact resistance and thermal stability, making it ideal for heavy-duty applications, while Makrolon by Covestro excels in UV resistance and color stability, favored in outdoor uses. Processing Lexan requires precise temperature control during injection molding to maintain its toughness, whereas Makrolon allows for more flexible fabrication methods including extrusion and thermoforming due to its improved flow properties. Both materials demonstrate excellent machinability, but Lexan typically demands slower cooling rates to prevent internal stresses, contrasting with Makrolon's faster processing cycles that enhance production efficiency.

Environmental Impact and Sustainability

Lexan and Makrolon polycarbonates differ in environmental impact, with both brands promoting recyclable materials but varying in their production energy efficiency and use of sustainable additives. Lexan, produced by SABIC, emphasizes green manufacturing processes and reduced carbon footprint through advanced resin formulations. Makrolon, manufactured by Covestro, focuses on incorporating recycled content and reducing volatile organic compounds, enhancing overall sustainability profiles.

Lexan vs Makrolon Infographic

materialdif.com

materialdif.com