UV stabilized polycarbonate offers enhanced resistance to yellowing, cracking, and degradation caused by prolonged exposure to sunlight compared to non-UV stabilized polycarbonate. This stabilization significantly extends the material's lifespan and maintains its optical clarity and mechanical strength in outdoor applications. Without UV stabilization, polycarbonate is prone to faster deterioration, compromising durability and performance over time.

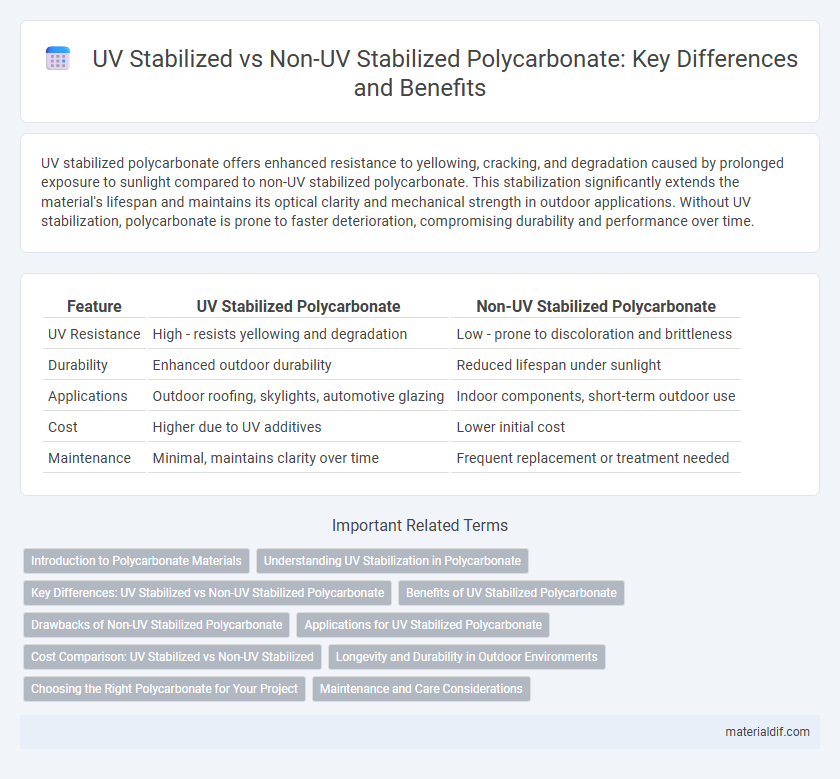

Table of Comparison

| Feature | UV Stabilized Polycarbonate | Non-UV Stabilized Polycarbonate |

|---|---|---|

| UV Resistance | High - resists yellowing and degradation | Low - prone to discoloration and brittleness |

| Durability | Enhanced outdoor durability | Reduced lifespan under sunlight |

| Applications | Outdoor roofing, skylights, automotive glazing | Indoor components, short-term outdoor use |

| Cost | Higher due to UV additives | Lower initial cost |

| Maintenance | Minimal, maintains clarity over time | Frequent replacement or treatment needed |

Introduction to Polycarbonate Materials

Polycarbonate materials offer exceptional impact resistance and optical clarity, making them ideal for various applications. UV stabilized polycarbonate includes additives that protect the material from degradation caused by ultraviolet radiation, extending durability and maintaining mechanical properties under prolonged sun exposure. Non-UV stabilized polycarbonate lacks these protective additives, resulting in increased susceptibility to yellowing, brittleness, and reduced lifespan when exposed to direct sunlight.

Understanding UV Stabilization in Polycarbonate

UV stabilized polycarbonate contains additives that absorb and dissipate ultraviolet radiation, significantly enhancing the material's resistance to UV-induced degradation such as discoloration, brittleness, and loss of mechanical strength. Non-UV stabilized polycarbonate lacks these protective additives, making it susceptible to rapid deterioration when exposed to sunlight, leading to reduced durability and a shorter lifespan. Understanding the role of UV stabilization is crucial for selecting polycarbonate materials in outdoor applications where prolonged exposure to sunlight is expected.

Key Differences: UV Stabilized vs Non-UV Stabilized Polycarbonate

UV stabilized polycarbonate features a protective coating or additive that blocks harmful ultraviolet radiation, significantly enhancing its resistance to yellowing, brittleness, and degradation when exposed to sunlight. Non-UV stabilized polycarbonate lacks this protection, resulting in faster deterioration and reduced clarity and mechanical strength over time under UV exposure. Choosing UV stabilized polycarbonate is essential for outdoor applications requiring long-term durability and optical clarity.

Benefits of UV Stabilized Polycarbonate

UV stabilized polycarbonate offers superior resistance to yellowing, cracking, and degradation caused by prolonged exposure to sunlight, significantly extending the material's lifespan. This enhanced durability preserves clarity and mechanical strength, making it ideal for outdoor applications such as roofing, glazing, and protective barriers. The UV inhibitor embedded within the polymer matrix effectively blocks harmful ultraviolet rays, ensuring sustained performance and aesthetic appeal over time.

Drawbacks of Non-UV Stabilized Polycarbonate

Non-UV stabilized polycarbonate experiences rapid yellowing and surface degradation when exposed to sunlight, severely reducing its optical clarity and structural integrity. This material shows increased brittleness and cracking over time due to ultraviolet radiation, leading to premature failure in outdoor applications. Lack of UV protection also results in loss of mechanical strength, making non-UV stabilized polycarbonate unsuitable for prolonged exposure to harsh environmental conditions.

Applications for UV Stabilized Polycarbonate

UV stabilized polycarbonate is engineered to resist degradation from prolonged sun exposure, making it ideal for outdoor applications such as greenhouse panels, skylights, and protective roofing. Its enhanced durability prevents yellowing and maintains optical clarity, significantly extending the lifespan of products subjected to UV radiation. Non-UV stabilized polycarbonate, lacking these protective additives, is better suited for indoor or low-UV environments where long-term exposure to sunlight is minimal.

Cost Comparison: UV Stabilized vs Non-UV Stabilized

UV stabilized polycarbonate typically incurs a higher initial cost compared to non-UV stabilized variants due to the added protective coatings that extend material longevity under sun exposure. Non-UV stabilized polycarbonate offers a lower upfront price but risks faster degradation and yellowing, leading to more frequent replacement expenses. Over time, UV stabilized polycarbonate often proves more cost-effective by reducing maintenance and replacement frequency in outdoor applications.

Longevity and Durability in Outdoor Environments

UV stabilized polycarbonate offers superior longevity and durability in outdoor environments by effectively resisting yellowing, cracking, and degradation caused by prolonged sun exposure. Non-UV stabilized polycarbonate degrades faster under UV radiation, resulting in reduced structural integrity and shorter lifespan when exposed to harsh weather conditions. Choosing UV stabilized formulations ensures optimal performance and extended service life for outdoor applications such as glazing, roofing, and protective coverings.

Choosing the Right Polycarbonate for Your Project

UV stabilized polycarbonate provides enhanced protection against ultraviolet radiation, preventing yellowing and degradation over time, making it ideal for outdoor applications exposed to sunlight. Non-UV stabilized polycarbonate offers cost-effective durability for indoor uses where UV exposure is minimal, maintaining clarity and strength without additional additives. Selecting the right polycarbonate depends on your project's exposure to UV light, longevity requirements, and budget constraints to ensure optimal performance and material lifespan.

Maintenance and Care Considerations

UV stabilized polycarbonate requires less frequent maintenance due to its enhanced resistance to yellowing and brittleness caused by prolonged sun exposure. Non-UV stabilized polycarbonate often demands regular cleaning and protective treatments to prevent degradation and maintain clarity. Proper care of UV stabilized materials extends their lifespan by up to 50% compared to non-treated counterparts, reducing replacement costs significantly.

UV Stabilized Polycarbonate vs Non-UV Stabilized Infographic

materialdif.com

materialdif.com