Polycarbonate offers exceptional optical clarity, making it ideal for applications requiring transparency and true color representation. When tinted, polycarbonate maintains its strength and impact resistance while reducing glare and controlling light transmission. This balance of clarity and tinting options allows for versatile use in eyewear, automotive lenses, and protective gear.

Table of Comparison

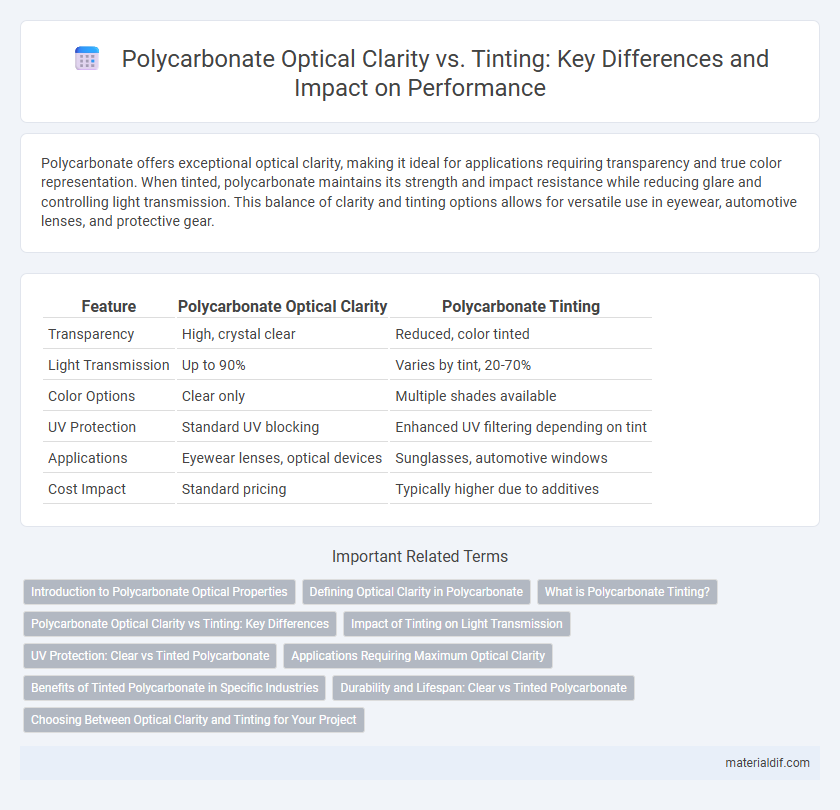

| Feature | Polycarbonate Optical Clarity | Polycarbonate Tinting |

|---|---|---|

| Transparency | High, crystal clear | Reduced, color tinted |

| Light Transmission | Up to 90% | Varies by tint, 20-70% |

| Color Options | Clear only | Multiple shades available |

| UV Protection | Standard UV blocking | Enhanced UV filtering depending on tint |

| Applications | Eyewear lenses, optical devices | Sunglasses, automotive windows |

| Cost Impact | Standard pricing | Typically higher due to additives |

Introduction to Polycarbonate Optical Properties

Polycarbonate exhibits exceptional optical clarity, allowing up to 90% light transmission, making it ideal for lenses, eyewear, and protective shields. Tinting polycarbonate materials can reduce glare and enhance UV protection but may slightly diminish overall transparency. Understanding the balance between optical clarity and tinting is crucial for optimizing performance in applications requiring both visibility and eye protection.

Defining Optical Clarity in Polycarbonate

Polycarbonate optical clarity refers to the material's ability to transmit light with minimal distortion, offering high transparency and exceptional visual sharpness. This property is critical for applications requiring precise vision, such as eyewear lenses and optical components. In contrast, polycarbonate tinting alters light transmission to reduce glare or provide UV protection without significantly compromising clarity.

What is Polycarbonate Tinting?

Polycarbonate tinting involves applying a colored film or coating to polycarbonate sheets to reduce glare and enhance visual comfort while maintaining durability. This process alters the optical clarity by selectively filtering light, which can improve contrast and reduce eye strain in bright environments. Tinting polycarbonate is commonly used in eyewear, automotive windows, and protective barriers to combine transparency with UV protection and aesthetic appeal.

Polycarbonate Optical Clarity vs Tinting: Key Differences

Polycarbonate optical clarity provides superior transparency with minimal light distortion, making it ideal for applications requiring precise visual accuracy such as eyewear lenses and optical equipment. In contrast, polycarbonate tinting introduces color to the material, which can reduce brightness and alter color perception but offers enhanced protection against UV rays and glare. The key differences lie in the balance between maintaining clear vision and providing protective shading, influencing the choice based on specific use cases.

Impact of Tinting on Light Transmission

Polycarbonate exhibits exceptional optical clarity with a high light transmission rate of approximately 90%, making it ideal for lenses and protective applications. Tinting polycarbonate reduces its light transmission significantly, often decreasing clarity by 20-30%, which can affect visual acuity and color perception. Effective tinting must balance UV protection and glare reduction while minimizing the impact on overall transparency and optical performance.

UV Protection: Clear vs Tinted Polycarbonate

Polycarbonate's optical clarity provides excellent UV protection by blocking nearly 100% of harmful UV rays without altering light transmission, making it ideal for applications requiring clear visibility. Tinted polycarbonate enhances UV protection by further reducing glare and controlling light intensity, beneficial in outdoor environments where eye comfort and UV defense are critical. Both clear and tinted polycarbonate maintain high impact resistance and durability, ensuring long-lasting protection against UV radiation.

Applications Requiring Maximum Optical Clarity

Polycarbonate optical clarity is essential in applications such as eyewear lenses, face shields, and high-performance optical components where transparency and minimal distortion are critical. While polycarbonate tinting enhances UV protection and reduces glare for outdoor use, it can slightly diminish light transmission and optical precision. Selecting untreated, clear polycarbonate ensures maximum visibility and accuracy in environments demanding flawless visual performance.

Benefits of Tinted Polycarbonate in Specific Industries

Tinted polycarbonate enhances visual comfort and reduces glare in automotive and aerospace industries, improving driver and pilot safety by minimizing eye strain under bright conditions. In the architectural sector, tinted polycarbonate panels contribute to energy efficiency by limiting solar heat gain while maintaining durability and impact resistance. Additionally, tinted polycarbonate provides UV protection for outdoor equipment and signage, extending lifespan and readability in harsh environmental conditions.

Durability and Lifespan: Clear vs Tinted Polycarbonate

Clear polycarbonate offers superior optical clarity, making it ideal for applications requiring maximum visibility and light transmission while maintaining high impact resistance. Tinted polycarbonate enhances UV protection and reduces glare, extending the material's durability under harsh sunlight exposure and minimizing yellowing or degradation over time. Both clear and tinted polycarbonate provide excellent lifespan; however, tinted variants typically demonstrate improved resistance to environmental aging, ensuring longer-lasting performance in outdoor conditions.

Choosing Between Optical Clarity and Tinting for Your Project

Polycarbonate offers exceptional optical clarity with high light transmission rates, making it ideal for applications that demand transparent, distortion-free visibility. Tinting polycarbonate introduces UV protection and reduces glare, enhancing comfort in outdoor or bright environments while slightly diminishing clarity. Selecting between optical clarity and tinting depends on project-specific needs such as visibility requirements, UV exposure, and aesthetic preferences.

Polycarbonate Optical Clarity vs Polycarbonate Tinting Infographic

materialdif.com

materialdif.com