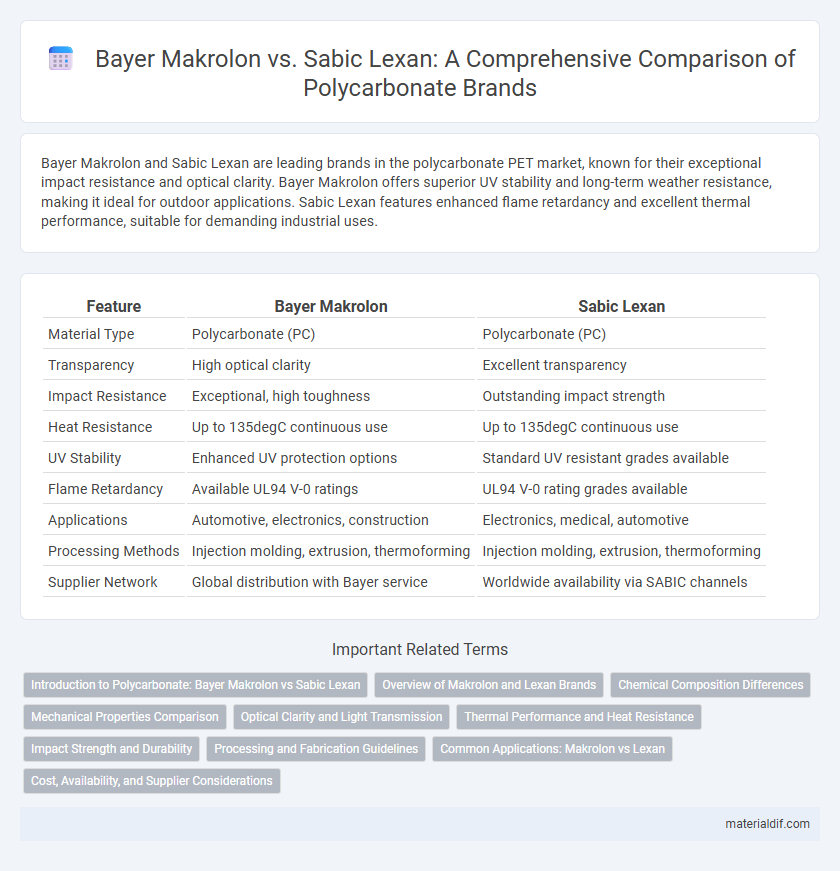

Bayer Makrolon and Sabic Lexan are leading brands in the polycarbonate PET market, known for their exceptional impact resistance and optical clarity. Bayer Makrolon offers superior UV stability and long-term weather resistance, making it ideal for outdoor applications. Sabic Lexan features enhanced flame retardancy and excellent thermal performance, suitable for demanding industrial uses.

Table of Comparison

| Feature | Bayer Makrolon | Sabic Lexan |

|---|---|---|

| Material Type | Polycarbonate (PC) | Polycarbonate (PC) |

| Transparency | High optical clarity | Excellent transparency |

| Impact Resistance | Exceptional, high toughness | Outstanding impact strength |

| Heat Resistance | Up to 135degC continuous use | Up to 135degC continuous use |

| UV Stability | Enhanced UV protection options | Standard UV resistant grades available |

| Flame Retardancy | Available UL94 V-0 ratings | UL94 V-0 rating grades available |

| Applications | Automotive, electronics, construction | Electronics, medical, automotive |

| Processing Methods | Injection molding, extrusion, thermoforming | Injection molding, extrusion, thermoforming |

| Supplier Network | Global distribution with Bayer service | Worldwide availability via SABIC channels |

Introduction to Polycarbonate: Bayer Makrolon vs Sabic Lexan

Bayer Makrolon and Sabic Lexan are two leading polycarbonate brands known for their high impact resistance, optical clarity, and thermal stability. Makrolon offers superior UV resistance and excellent dimensional stability, making it ideal for outdoor applications, while Lexan is favored for its versatility and broad chemical resistance across industrial uses. Both brands leverage polycarbonate's unique combination of strength and transparency, serving critical roles in automotive, electronics, and construction sectors.

Overview of Makrolon and Lexan Brands

Makrolon by Bayer is renowned for its high impact resistance and clarity, making it ideal for automotive parts, electronics, and construction applications. Lexan, produced by Sabic, offers superior thermal stability and UV resistance, widely used in glazing, signage, and medical devices. Both brands deliver premium polycarbonate solutions with distinct performance attributes tailored to diverse industrial needs.

Chemical Composition Differences

Bayer Makrolon and Sabic Lexan both utilize bisphenol A as the primary monomer in their polycarbonate formulations, but differences in additives and stabilizers impact performance and durability. Makrolon often employs proprietary UV stabilizers and optical brighteners to enhance weather resistance and clarity, while Lexan incorporates specific flame retardants and impact modifiers tailored for high-strength applications. These subtle chemical composition variations influence thermal stability, transparency, and mechanical properties across both brands.

Mechanical Properties Comparison

Bayer Makrolon and Sabic Lexan are both high-performance polycarbonate materials known for exceptional mechanical strength and durability. Makrolon offers superior impact resistance and higher tensile strength, making it ideal for demanding engineering applications, while Lexan provides excellent flexibility and toughness with slightly better elongation at break. Both materials exhibit high heat resistance and dimensional stability, but Bayer Makrolon's mechanical properties are often preferred for applications requiring maximum rigidity and impact performance.

Optical Clarity and Light Transmission

Bayer Makrolon and Sabic Lexan are both premium polycarbonate brands known for superior optical clarity and high light transmission rates, typically exceeding 88%, making them ideal for applications requiring clear visibility. Bayer Makrolon often exhibits slightly better UV stability and haze resistance, enhancing long-term transparency in outdoor and high-exposure environments. Sabic Lexan offers comparable optical performance with consistent clarity and excellent impact resistance, making both materials suitable for demanding optical and glazing applications.

Thermal Performance and Heat Resistance

Bayer Makrolon polycarbonate exhibits superior thermal performance with a high glass transition temperature around 150degC, ensuring excellent heat resistance and dimensional stability under elevated temperatures. Sabic Lexan also offers robust heat resistance but generally features a slightly lower continuous use temperature range, typically up to 130degC, making it suitable for slightly less demanding thermal environments. Both materials provide strong performance in thermal applications, but Bayer Makrolon's enhanced heat deflection temperature makes it preferable for high-heat industrial uses.

Impact Strength and Durability

Bayer Makrolon polycarbonate offers exceptional impact strength with high resistance to shattering, making it ideal for demanding applications requiring maximum durability. Sabic Lexan also delivers robust impact resistance but emphasizes superior weatherability and long-term UV protection for outdoor use. Both materials ensure outstanding toughness, though Makrolon's impact strength slightly surpasses Lexan's in heavy-duty environments.

Processing and Fabrication Guidelines

Bayer Makrolon polycarbonate offers excellent processability with precise injection molding temperature ranges between 260-320degC, ensuring high-quality part consistency and minimal thermal degradation. Sabic Lexan provides robust heat resistance and superior flow characteristics, enabling efficient extrusion and thermoforming at temperatures of 270-300degC, which reduces cycle times and improves surface finish. Both materials require careful moisture control prior to processing to prevent hydrolysis, with recommended pre-drying at 120degC for 2-4 hours to optimize fabrication outcomes.

Common Applications: Makrolon vs Lexan

Bayer Makrolon and Sabic Lexan are leading polycarbonate brands widely used for architectural glazing, automotive components, and electronic device covers due to their high impact resistance and transparency. Makrolon is often preferred in safety glazing and electrical insulation applications because of its superior thermal stability and UV resistance. Lexan excels in outdoor signage, medical equipment, and riot shields, benefiting from its excellent balance of toughness and optical clarity.

Cost, Availability, and Supplier Considerations

Bayer Makrolon polycarbonate is known for its consistent quality and widespread availability, often priced higher due to its premium brand reputation and strict manufacturing standards. Sabic Lexan offers a cost-effective alternative with competitive pricing and broad global distribution, making it attractive for high-volume applications where cost efficiency is critical. Supplier considerations for both include global support networks and extensive technical assistance, but availability may vary regionally, impacting lead times and procurement strategies.

Bayer Makrolon vs Sabic Lexan Infographic

materialdif.com

materialdif.com