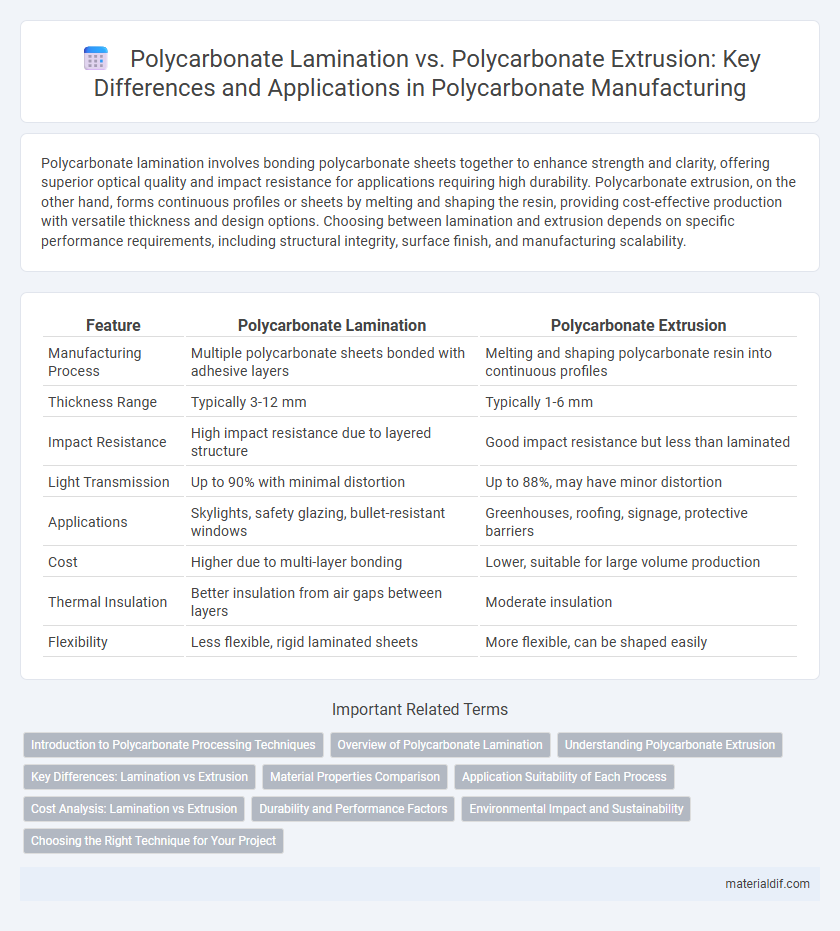

Polycarbonate lamination involves bonding polycarbonate sheets together to enhance strength and clarity, offering superior optical quality and impact resistance for applications requiring high durability. Polycarbonate extrusion, on the other hand, forms continuous profiles or sheets by melting and shaping the resin, providing cost-effective production with versatile thickness and design options. Choosing between lamination and extrusion depends on specific performance requirements, including structural integrity, surface finish, and manufacturing scalability.

Table of Comparison

| Feature | Polycarbonate Lamination | Polycarbonate Extrusion |

|---|---|---|

| Manufacturing Process | Multiple polycarbonate sheets bonded with adhesive layers | Melting and shaping polycarbonate resin into continuous profiles |

| Thickness Range | Typically 3-12 mm | Typically 1-6 mm |

| Impact Resistance | High impact resistance due to layered structure | Good impact resistance but less than laminated |

| Light Transmission | Up to 90% with minimal distortion | Up to 88%, may have minor distortion |

| Applications | Skylights, safety glazing, bullet-resistant windows | Greenhouses, roofing, signage, protective barriers |

| Cost | Higher due to multi-layer bonding | Lower, suitable for large volume production |

| Thermal Insulation | Better insulation from air gaps between layers | Moderate insulation |

| Flexibility | Less flexible, rigid laminated sheets | More flexible, can be shaped easily |

Introduction to Polycarbonate Processing Techniques

Polycarbonate lamination involves bonding multiple polycarbonate sheets with adhesive layers, enhancing impact resistance and optical clarity for applications like glazing and displays. Polycarbonate extrusion melts and forces resin through a die to create continuous profiles or sheets, enabling customized thickness and shapes for construction and automotive industries. Both techniques optimize polycarbonate's durability and versatility, but lamination emphasizes layered strength while extrusion prioritizes precise dimensional control.

Overview of Polycarbonate Lamination

Polycarbonate lamination involves bonding multiple sheets or films of polycarbonate using adhesives or heat, resulting in enhanced strength, clarity, and impact resistance compared to single-layer materials. This process improves optical properties and provides additional protection against UV radiation, making laminated polycarbonate ideal for applications such as glazing, automotive components, and security panels. Lamination also allows customization in thickness and flexibility, offering superior durability and resistance to environmental stressors compared to polycarbonate extrusion.

Understanding Polycarbonate Extrusion

Polycarbonate extrusion involves melting raw polycarbonate pellets and shaping them into continuous profiles, sheets, or films through a die, providing precise control over thickness, texture, and mechanical properties. This process offers superior consistency and durability compared to lamination, making extruded polycarbonate ideal for applications requiring impact resistance and clarity, such as glazing, automotive parts, and electronic components. Extruded polycarbonate sheets exhibit excellent dimensional stability and UV resistance, enhancing their performance in demanding environments.

Key Differences: Lamination vs Extrusion

Polycarbonate lamination involves bonding multiple layers of polycarbonate sheets with adhesive to enhance impact resistance, optical clarity, and UV protection, while polycarbonate extrusion shapes molten polycarbonate into continuous profiles or sheets through a die for uniform thickness and structural integrity. Lamination allows customization of properties by combining different layers, making it ideal for applications requiring enhanced durability and multifunctionality, whereas extrusion focuses on producing consistent, high-strength components with smooth surfaces for construction and manufacturing uses. The key differences lie in the manufacturing process, end-product characteristics, and ability to tailor performance features.

Material Properties Comparison

Polycarbonate lamination offers enhanced impact resistance and superior optical clarity due to the bonding of multiple polycarbonate sheets, making it ideal for applications requiring high durability and transparency. Polycarbonate extrusion provides greater design flexibility and uniform thickness, resulting in consistent mechanical strength suitable for structural components with precise tolerances. Both methods leverage polycarbonate's inherent properties such as high heat resistance, UV stability, and excellent dimensional stability, but lamination excels in layered protection while extrusion emphasizes form and consistency.

Application Suitability of Each Process

Polycarbonate lamination provides enhanced surface durability and UV resistance, making it ideal for applications like automotive glazing and protective shields where clarity and scratch resistance are crucial. Polycarbonate extrusion offers greater flexibility in creating custom profiles for construction elements such as roofing panels and light diffusers, emphasizing ease of fabrication and consistent thickness. Selecting between lamination and extrusion depends on the specific requirements for impact resistance, optical clarity, and structural complexity in the target application.

Cost Analysis: Lamination vs Extrusion

Polycarbonate lamination typically incurs higher production costs due to the multi-layer bonding process and the use of adhesives, which increase material and labor expenses. In contrast, polycarbonate extrusion offers a cost-effective solution by producing continuous sheets with less manual intervention and lower scrap rates. Businesses seeking budget-friendly options often prefer extrusion methods for large-volume orders, while lamination is favored for specialized applications requiring enhanced material properties despite the premium price.

Durability and Performance Factors

Polycarbonate lamination enhances impact resistance and UV protection by bonding multiple sheets into a single, robust panel that withstands harsh environmental conditions. Polycarbonate extrusion produces continuous sheets with consistent thickness and optical clarity, offering superior dimensional stability and resistance to warping under stress. Durability in laminated polycarbonate excels in high-impact applications, while extruded polycarbonate delivers better uniformity and mechanical strength for structural uses.

Environmental Impact and Sustainability

Polycarbonate lamination typically involves bonding multiple layers with adhesives, resulting in higher chemical waste and energy consumption compared to polycarbonate extrusion, which shapes materials directly with less processing. Extruded polycarbonate offers greater recyclability due to its homogenous structure, reducing environmental impact and promoting sustainability. Choosing extrusion over lamination supports lower carbon emissions and resource efficiency in polycarbonate manufacturing.

Choosing the Right Technique for Your Project

Polycarbonate lamination offers superior impact resistance and clarity by bonding multiple layers for enhanced strength, making it ideal for security applications and optical clarity needs. Polycarbonate extrusion produces uniform sheets with excellent dimensional stability and cost-effectiveness, suitable for large-volume roofing or glazing projects. Selecting the right technique depends on project requirements like durability, transparency, and budget constraints to optimize performance and cost-efficiency.

Polycarbonate Lamination vs Polycarbonate Extrusion Infographic

materialdif.com

materialdif.com