Polycarbonate offers exceptional impact resistance and clarity, making it ideal for applications requiring transparency and durability. Glass-filled polycarbonate enhances mechanical strength and rigidity by incorporating glass fibers, providing superior dimensional stability in high-stress environments. Choosing between polycarbonate and glass-filled polycarbonate depends on the specific need for flexibility or reinforced structural integrity in the final product.

Table of Comparison

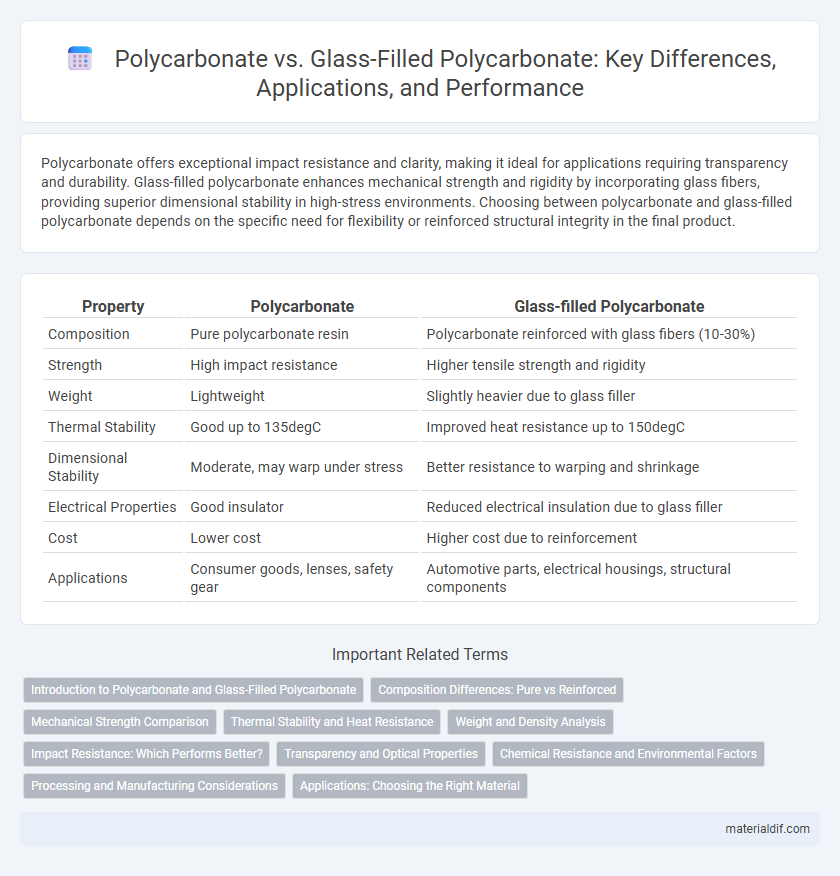

| Property | Polycarbonate | Glass-filled Polycarbonate |

|---|---|---|

| Composition | Pure polycarbonate resin | Polycarbonate reinforced with glass fibers (10-30%) |

| Strength | High impact resistance | Higher tensile strength and rigidity |

| Weight | Lightweight | Slightly heavier due to glass filler |

| Thermal Stability | Good up to 135degC | Improved heat resistance up to 150degC |

| Dimensional Stability | Moderate, may warp under stress | Better resistance to warping and shrinkage |

| Electrical Properties | Good insulator | Reduced electrical insulation due to glass filler |

| Cost | Lower cost | Higher cost due to reinforcement |

| Applications | Consumer goods, lenses, safety gear | Automotive parts, electrical housings, structural components |

Introduction to Polycarbonate and Glass-Filled Polycarbonate

Polycarbonate is a durable, transparent thermoplastic known for its high impact resistance and optical clarity, commonly used in eyewear lenses, optical discs, and automotive components. Glass-filled polycarbonate combines polycarbonate resin with glass fibers, enhancing its mechanical strength, stiffness, and thermal stability, making it suitable for demanding industrial applications such as electrical housings and structural parts. The addition of glass fibers alters the material's performance characteristics by increasing dimensional stability and wear resistance while maintaining many of the advantageous properties of standard polycarbonate.

Composition Differences: Pure vs Reinforced

Polycarbonate consists of a transparent thermoplastic polymer known for its high impact resistance and optical clarity, primarily composed of bisphenol A and carbonate groups. Glass-filled polycarbonate incorporates glass fiber reinforcements, typically ranging from 10% to 30% by weight, significantly enhancing mechanical strength, stiffness, and dimensional stability. The addition of glass fibers alters the composite's thermal properties and reduces its flexibility compared to pure polycarbonate, making it suitable for applications demanding higher structural integrity.

Mechanical Strength Comparison

Polycarbonate exhibits high impact resistance and flexibility, making it suitable for applications requiring toughness and durability. Glass-filled polycarbonate enhances mechanical strength by incorporating glass fibers, significantly increasing tensile strength, stiffness, and dimensional stability compared to standard polycarbonate. This reinforcement results in improved wear resistance and reduced deformation under heavy loads, ideal for engineering applications demanding greater structural integrity.

Thermal Stability and Heat Resistance

Polycarbonate exhibits good thermal stability with a heat deflection temperature around 130degC, making it suitable for various applications. Glass-filled polycarbonate enhances thermal stability significantly, often increasing the heat deflection temperature to approximately 160-170degC due to the reinforcement of glass fibers. This improved heat resistance makes glass-filled polycarbonate ideal for high-temperature environments where superior mechanical strength and dimensional stability are required.

Weight and Density Analysis

Polycarbonate exhibits a density of approximately 1.2 g/cm3, making it significantly lighter than glass-filled polycarbonate, which typically ranges from 1.3 to 1.5 g/cm3 due to the inclusion of glass fibers. The added glass fibers in glass-filled polycarbonate increase both the weight and density, enhancing mechanical strength but compromising lightweight properties. Manufacturers prioritize pure polycarbonate in applications demanding low weight, while choosing glass-filled variants for improved rigidity and dimensional stability.

Impact Resistance: Which Performs Better?

Polycarbonate offers excellent impact resistance, making it highly durable and resistant to shattering under stress. Glass-filled polycarbonate enhances mechanical strength and stiffness but tends to have reduced impact resistance compared to standard polycarbonate due to the glass fiber reinforcement. For applications requiring maximum impact resistance, pure polycarbonate typically outperforms glass-filled variants.

Transparency and Optical Properties

Polycarbonate offers high transparency with light transmission rates up to 89%, making it ideal for optical clarity applications. Glass-filled polycarbonate, while enhanced for strength and rigidity by the addition of glass fibers, typically shows reduced transparency and increased opacity due to light scattering caused by the glass content. Optical properties of glass-filled polycarbonate include lower clarity and increased haze, limiting its use in applications where clear visibility is critical.

Chemical Resistance and Environmental Factors

Polycarbonate offers excellent chemical resistance to oils, diluted acids, and alkalis, but glass-filled polycarbonate enhances durability against aggressive chemicals and solvents due to its reinforced structure. Environmental factors such as UV exposure and temperature fluctuations impact both materials, with glass-filled polycarbonate providing superior heat resistance and improved dimensional stability under thermal stress. This makes glass-filled polycarbonate a preferred choice in harsh chemical environments and outdoor applications requiring long-term performance.

Processing and Manufacturing Considerations

Polycarbonate offers easier processing with lower mold temperatures and faster cycle times compared to glass-filled polycarbonate, which requires higher temperatures and pressures due to reinforced fibers. Glass-filled polycarbonate provides enhanced mechanical strength and dimensional stability but demands more precise mold design and tooling to manage fiber orientation and potential wear. Manufacturing processes must account for these differences to optimize product quality and production efficiency in applications requiring specific performance characteristics.

Applications: Choosing the Right Material

Polycarbonate offers excellent impact resistance and clarity, making it ideal for applications like eyewear lenses and protective shields. Glass-filled polycarbonate provides enhanced strength and heat resistance, suited for automotive parts, electrical components, and industrial machinery housings. Selecting the right material depends on balancing durability requirements and environmental exposure in specific applications.

Polycarbonate vs Glass-filled Polycarbonate Infographic

materialdif.com

materialdif.com