Polycarbonate PET exhibits exceptional impact resistance, making it ideal for applications requiring durability under heavy stress or sudden force. However, its scratch resistance is comparatively lower, necessitating protective coatings or careful handling to maintain surface clarity. Balancing impact and scratch resistance is crucial in selecting polycarbonate PET for protective gear, eyewear, or electronic screens where both toughness and appearance matter.

Table of Comparison

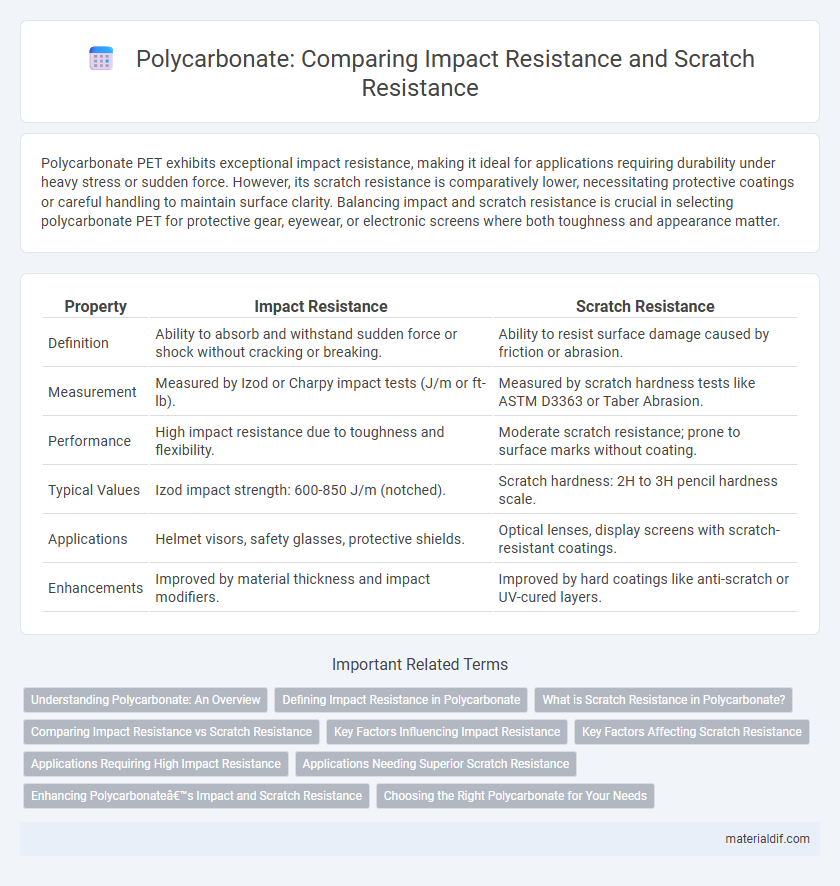

| Property | Impact Resistance | Scratch Resistance |

|---|---|---|

| Definition | Ability to absorb and withstand sudden force or shock without cracking or breaking. | Ability to resist surface damage caused by friction or abrasion. |

| Measurement | Measured by Izod or Charpy impact tests (J/m or ft-lb). | Measured by scratch hardness tests like ASTM D3363 or Taber Abrasion. |

| Performance | High impact resistance due to toughness and flexibility. | Moderate scratch resistance; prone to surface marks without coating. |

| Typical Values | Izod impact strength: 600-850 J/m (notched). | Scratch hardness: 2H to 3H pencil hardness scale. |

| Applications | Helmet visors, safety glasses, protective shields. | Optical lenses, display screens with scratch-resistant coatings. |

| Enhancements | Improved by material thickness and impact modifiers. | Improved by hard coatings like anti-scratch or UV-cured layers. |

Understanding Polycarbonate: An Overview

Polycarbonate exhibits exceptional impact resistance, making it highly durable against shocks and drops, which is essential for safety applications like helmets and automotive components. However, its scratch resistance is relatively lower compared to tempered glass, requiring protective coatings or treatments to maintain clarity and surface integrity. Understanding these properties helps optimize polycarbonate use in industries demanding both toughness and aesthetic longevity.

Defining Impact Resistance in Polycarbonate

Impact resistance in polycarbonate refers to its ability to absorb and dissipate energy from sudden forces or shocks without cracking or breaking. This thermoplastic polymer is renowned for its high toughness, allowing it to withstand impacts that would shatter ordinary plastics. Unlike scratch resistance, which relates to surface durability, impact resistance ensures structural integrity under mechanical stress.

What is Scratch Resistance in Polycarbonate?

Scratch resistance in polycarbonate refers to the material's ability to withstand surface abrasions and maintain clarity despite everyday wear and tear. This property is enhanced by applying hard coatings that protect the polycarbonate from fine scratches caused by friction, dust, or rough handling. While polycarbonate inherently offers excellent impact resistance, its scratch resistance requires specialized treatments to preserve its optical quality and durability.

Comparing Impact Resistance vs Scratch Resistance

Polycarbonate exhibits exceptional impact resistance, making it ideal for applications requiring high durability against shocks and drops, outperforming materials like glass and acrylic. However, its scratch resistance is comparatively lower, necessitating protective coatings or treatments to maintain surface clarity and prevent abrasion damage. Balancing impact resistance with enhanced scratch resistance solutions ensures polycarbonate remains a versatile choice for safety gear, automotive parts, and electronic displays.

Key Factors Influencing Impact Resistance

Polycarbonate's exceptional impact resistance is primarily influenced by its molecular structure, which enables high energy absorption and stress distribution upon impact. Factors such as thickness, temperature, and the presence of additives like UV stabilizers or plasticizers significantly affect its toughness and durability under sudden forces. While polycarbonate excels at impact resistance, its scratch resistance can be enhanced through hard coatings or surface treatments without compromising strength.

Key Factors Affecting Scratch Resistance

Polycarbonate's scratch resistance is primarily influenced by surface hardness, coating quality, and environmental exposure, with harder coatings significantly reducing abrasion and surface damage. Impact resistance depends on the polymer's molecular structure and thickness, where a tough, flexible matrix absorbs energy without cracking, but this does not necessarily improve scratch resistance. Understanding the balance between hardness-enhancing treatments and the inherent toughness of polycarbonate is crucial for applications requiring both durability and clarity.

Applications Requiring High Impact Resistance

Polycarbonate is renowned for its exceptional impact resistance, making it ideal for applications such as safety helmets, automotive parts, and bulletproof windows that demand high durability against sudden shocks. While it offers moderate scratch resistance, its primary advantage lies in absorbing and dispersing impact energy without cracking. Protective coatings can enhance scratch resistance, but polycarbonate's unmatched toughness remains the key factor in high-impact environments.

Applications Needing Superior Scratch Resistance

Polycarbonate offers excellent impact resistance, making it ideal for applications prone to high mechanical stress such as safety helmets and automotive components. However, superior scratch resistance is crucial for touch-sensitive devices like smartphone screens and eyewear lenses, where surface clarity and durability are paramount. Specialized coatings enhance polycarbonate's scratch resistance, ensuring longevity in products subject to frequent handling and abrasion.

Enhancing Polycarbonate’s Impact and Scratch Resistance

Polycarbonate's impact resistance can be significantly enhanced through the incorporation of acrylic or other polymer blends, which improve its toughness and ability to absorb energy during high-impact events. Scratch resistance is optimized by applying hard coatings such as silicon oxide or diamond-like carbon layers, providing a durable surface that resists abrasion without compromising transparency. Advanced manufacturing techniques that combine these treatments enable polycarbonate to maintain both high impact strength and surface durability, extending its usability in demanding applications like automotive and protective eyewear.

Choosing the Right Polycarbonate for Your Needs

Polycarbonate offers exceptional impact resistance, making it ideal for applications requiring durability against shocks and drops. However, its scratch resistance varies depending on surface coatings, so selecting polycarbonate with a hard coating is crucial for environments prone to abrasion. Balancing impact and scratch resistance ensures optimal performance tailored to specific needs, such as safety gear or protective glazing.

Impact Resistance vs Scratch Resistance Infographic

materialdif.com

materialdif.com