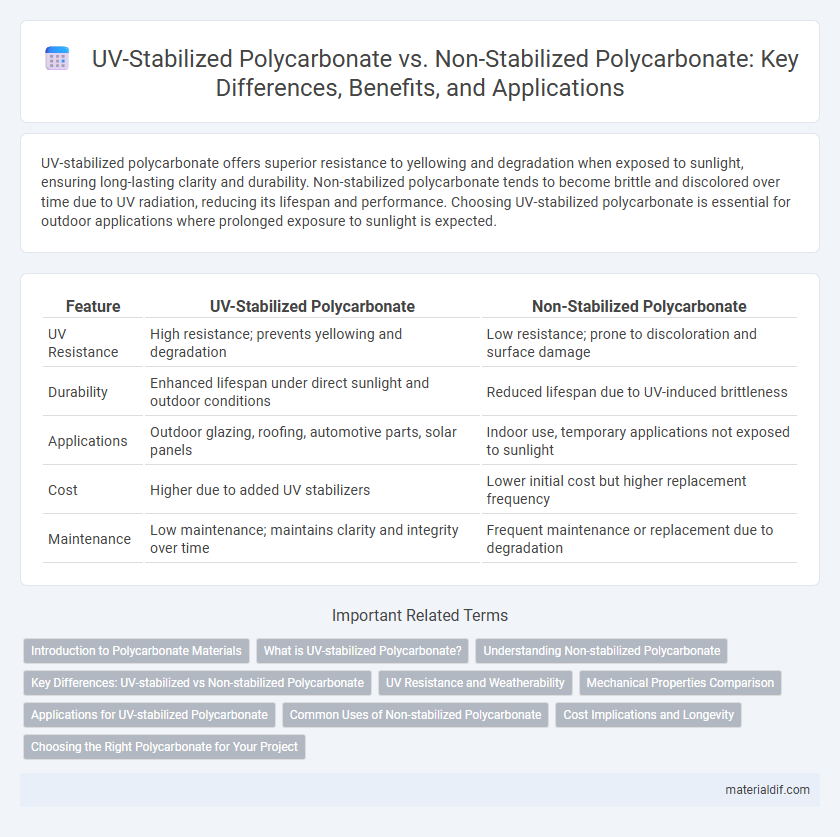

UV-stabilized polycarbonate offers superior resistance to yellowing and degradation when exposed to sunlight, ensuring long-lasting clarity and durability. Non-stabilized polycarbonate tends to become brittle and discolored over time due to UV radiation, reducing its lifespan and performance. Choosing UV-stabilized polycarbonate is essential for outdoor applications where prolonged exposure to sunlight is expected.

Table of Comparison

| Feature | UV-Stabilized Polycarbonate | Non-Stabilized Polycarbonate |

|---|---|---|

| UV Resistance | High resistance; prevents yellowing and degradation | Low resistance; prone to discoloration and surface damage |

| Durability | Enhanced lifespan under direct sunlight and outdoor conditions | Reduced lifespan due to UV-induced brittleness |

| Applications | Outdoor glazing, roofing, automotive parts, solar panels | Indoor use, temporary applications not exposed to sunlight |

| Cost | Higher due to added UV stabilizers | Lower initial cost but higher replacement frequency |

| Maintenance | Low maintenance; maintains clarity and integrity over time | Frequent maintenance or replacement due to degradation |

Introduction to Polycarbonate Materials

UV-stabilized polycarbonate incorporates additives that significantly enhance its resistance to ultraviolet radiation, preventing yellowing and degradation when exposed to sunlight. Non-stabilized polycarbonate lacks these protective agents, making it prone to discoloration, reduced mechanical strength, and surface cracking over time under UV exposure. This distinction is crucial for applications requiring long-term outdoor durability, such as glazing, automotive components, and protective equipment.

What is UV-stabilized Polycarbonate?

UV-stabilized polycarbonate is engineered with additives that protect the material from degradation caused by ultraviolet (UV) radiation, significantly enhancing its durability and lifespan in outdoor applications. Unlike non-stabilized polycarbonate, which tends to yellow, become brittle, and lose mechanical strength when exposed to sunlight, UV-stabilized variants maintain clarity, impact resistance, and structural integrity under prolonged UV exposure. This makes UV-stabilized polycarbonate ideal for use in glazing, roofing, and outdoor signage where long-term resistance to weathering is critical.

Understanding Non-stabilized Polycarbonate

Non-stabilized polycarbonate lacks protective additives that shield it from ultraviolet (UV) radiation, leading to rapid degradation when exposed to sunlight. This degradation results in yellowing, loss of mechanical strength, and increased brittleness, significantly reducing the material's lifespan in outdoor applications. Understanding these limitations is crucial for selecting the right polycarbonate type for environments with high UV exposure.

Key Differences: UV-stabilized vs Non-stabilized Polycarbonate

UV-stabilized polycarbonate contains additives that protect the material from degradation caused by ultraviolet radiation, enhancing its durability and preventing yellowing over time. Non-stabilized polycarbonate lacks these additives, making it more susceptible to UV damage, resulting in reduced clarity and structural integrity when exposed to sunlight. The presence of UV stabilizers significantly extends the lifespan and maintains the optical properties of polycarbonate in outdoor applications.

UV Resistance and Weatherability

UV-stabilized polycarbonate offers superior UV resistance and weatherability compared to non-stabilized polycarbonate, significantly reducing yellowing, cracking, and surface degradation caused by prolonged sun exposure. The incorporation of UV stabilizers absorbs and dissipates harmful UV radiation, extending the material's lifespan in outdoor applications. Non-stabilized polycarbonate lacks this protection, leading to rapid deterioration and loss of mechanical properties when exposed to harsh environmental conditions.

Mechanical Properties Comparison

UV-stabilized polycarbonate exhibits enhanced mechanical properties such as increased impact resistance and tensile strength compared to non-stabilized polycarbonate, which tends to degrade and become brittle under prolonged UV exposure. The incorporation of UV stabilizers prevents polymer chain scission, preserving the material's durability and flexibility in outdoor applications. As a result, UV-stabilized polycarbonate maintains superior load-bearing capacity and dimensional stability over time versus its non-stabilized counterpart.

Applications for UV-stabilized Polycarbonate

UV-stabilized polycarbonate offers enhanced resistance to yellowing and degradation when exposed to prolonged sunlight, making it ideal for outdoor applications such as greenhouse panels, skylights, and automotive headlamp covers. Its ability to maintain optical clarity and mechanical strength under UV exposure extends the lifespan of products exposed to harsh environmental conditions. Non-stabilized polycarbonate, while suitable for indoor uses, degrades faster when exposed to UV light, limiting its performance in exterior applications.

Common Uses of Non-stabilized Polycarbonate

Non-stabilized polycarbonate is commonly used in applications where UV exposure is minimal or controlled, such as indoor electrical enclosures, optical lenses, and automotive interior components. Its high impact resistance and excellent clarity make it ideal for protective covers, eyewear, and lighting fixtures within environments shielded from direct sunlight. These properties enable cost-effective solutions without the added expense of UV stabilization.

Cost Implications and Longevity

UV-stabilized polycarbonate offers significantly enhanced resistance to sun damage, extending its lifespan by up to 10 years compared to non-stabilized variants, which can degrade within 3 to 5 years under UV exposure. The initial cost of UV-stabilized polycarbonate is approximately 20-30% higher, but this investment reduces long-term replacement and maintenance expenses. Choosing UV-stabilized polycarbonate provides superior durability and cost efficiency for outdoor applications exposed to sunlight.

Choosing the Right Polycarbonate for Your Project

UV-stabilized polycarbonate offers enhanced resistance to yellowing and degradation caused by prolonged exposure to sunlight, making it ideal for outdoor applications such as greenhouses, skylights, and protective glazing. Non-stabilized polycarbonate, while more cost-effective, is better suited for indoor projects where UV exposure is minimal, ensuring clarity and strength without the need for added UV protection. Selecting the right polycarbonate depends on environmental conditions, lifespan requirements, and budget considerations to achieve optimal durability and performance.

UV-stabilized Polycarbonate vs Non-stabilized Polycarbonate Infographic

materialdif.com

materialdif.com