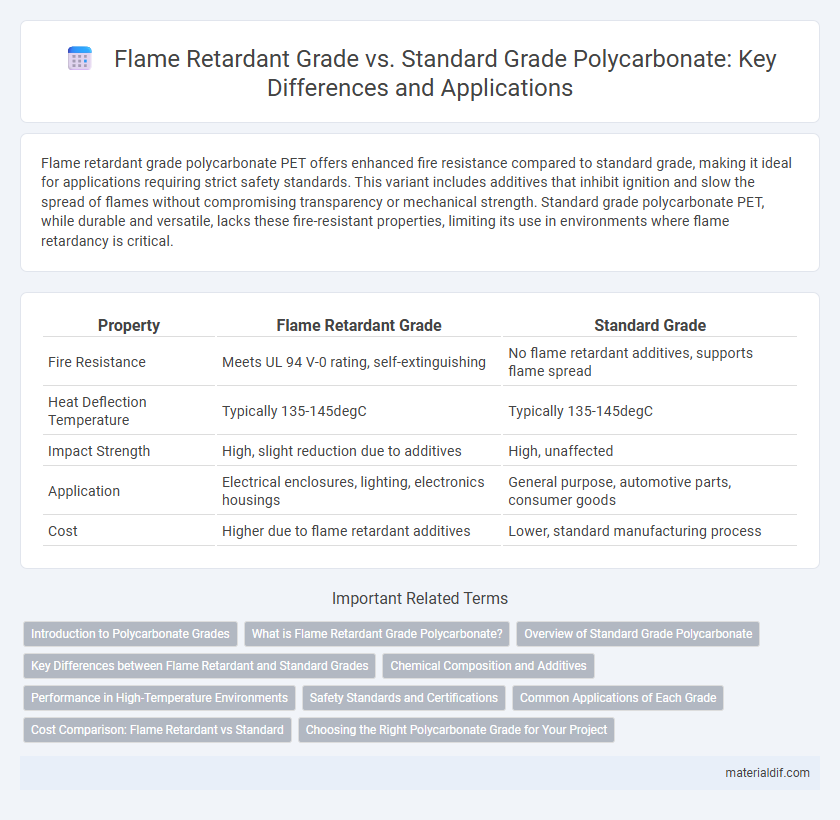

Flame retardant grade polycarbonate PET offers enhanced fire resistance compared to standard grade, making it ideal for applications requiring strict safety standards. This variant includes additives that inhibit ignition and slow the spread of flames without compromising transparency or mechanical strength. Standard grade polycarbonate PET, while durable and versatile, lacks these fire-resistant properties, limiting its use in environments where flame retardancy is critical.

Table of Comparison

| Property | Flame Retardant Grade | Standard Grade |

|---|---|---|

| Fire Resistance | Meets UL 94 V-0 rating, self-extinguishing | No flame retardant additives, supports flame spread |

| Heat Deflection Temperature | Typically 135-145degC | Typically 135-145degC |

| Impact Strength | High, slight reduction due to additives | High, unaffected |

| Application | Electrical enclosures, lighting, electronics housings | General purpose, automotive parts, consumer goods |

| Cost | Higher due to flame retardant additives | Lower, standard manufacturing process |

Introduction to Polycarbonate Grades

Polycarbonate grades are specifically formulated to meet different performance requirements, with Flame Retardant Grade designed to enhance fire resistance by incorporating special additives that limit flame propagation. Standard Grade polycarbonate offers excellent impact resistance and optical clarity but lacks these fire-retardant properties, making Flame Retardant Grade essential for applications requiring compliance with stringent fire safety standards. Selection between these grades depends on the balance of electrical insulation, mechanical strength, and fire safety regulations in industries such as electronics, automotive, and construction.

What is Flame Retardant Grade Polycarbonate?

Flame Retardant Grade Polycarbonate is engineered to meet stringent fire safety standards by incorporating additives that inhibit or resist combustion, reducing the material's flammability and smoke production. This grade is essential for applications demanding high fire resistance, such as electrical components, automotive parts, and construction materials. Compared to Standard Grade Polycarbonate, the flame retardant variant offers enhanced thermal stability and improved performance in emergency conditions without compromising mechanical strength or transparency.

Overview of Standard Grade Polycarbonate

Standard grade polycarbonate offers excellent impact resistance, optical clarity, and dimensional stability, making it suitable for a wide range of applications such as automotive components, electronic housings, and consumer goods. Unlike flame retardant grade, it does not include fire-resistant additives, which means it has lower flame retardancy but often better processability and cost-effectiveness. Standard grade polycarbonate typically complies with general industry standards but is not suitable for environments requiring stringent fire safety regulations.

Key Differences between Flame Retardant and Standard Grades

Flame retardant grade polycarbonate contains specialized additives like brominated compounds that significantly enhance its resistance to ignition and slow down flame propagation compared to standard grade, which typically lacks these fire-resistant formulations. The flame retardant variant exhibits higher UL 94 V-0 or V-1 ratings, indicating superior performance in fire safety tests, while standard grade polycarbonate meets basic mechanical and thermal requirements without enhanced flame protection. Furthermore, flame retardant grades may show slight differences in optical clarity and mechanical strength due to additive integration, impacting applications where both fire safety and material transparency are critical.

Chemical Composition and Additives

Flame retardant grade polycarbonate contains specialized additives such as halogenated compounds, phosphorus-based agents, and metal oxides that enhance its resistance to ignition and flame propagation. In contrast, standard grade polycarbonate primarily relies on a pure polymer matrix with minimal or no flame-retardant additives, resulting in lower fire-resistance performance. The chemical composition of flame retardant polycarbonate is engineered to comply with strict fire safety standards like UL 94 V-0, whereas standard grade formulations focus more on mechanical strength and optical clarity without enhanced flame-retardant properties.

Performance in High-Temperature Environments

Flame retardant grade polycarbonate exhibits superior thermal stability and self-extinguishing properties compared to standard grade, making it ideal for high-temperature environments exceeding 120degC. Its enhanced flame resistance prevents ignition and reduces smoke release during fire exposure, complying with UL 94 V-0 standards. Standard grade polycarbonate, while offering good mechanical strength, lacks the specialized additives that ensure continuous performance and safety in elevated temperature applications.

Safety Standards and Certifications

Flame retardant grade polycarbonate meets stringent safety standards such as UL 94 V-0 and EN 13501-1, ensuring superior fire resistance compared to standard grade polycarbonate typically rated at UL 94 HB. Certifications from recognized bodies like Underwriters Laboratories and TUV Rheinland validate its compliance with international fire safety regulations, making it suitable for applications in electronics, automotive, and construction. Standard grade polycarbonate lacks these advanced flame retardant certifications, limiting its use where stringent fire safety requirements are mandatory.

Common Applications of Each Grade

Flame retardant grade polycarbonate is commonly applied in electrical and electronic components, automotive parts, and construction materials where enhanced fire resistance is critical. Standard grade polycarbonate is widely used in optical lenses, consumer electronics cases, and medical devices due to its clarity and impact resistance. Selecting the appropriate grade ensures compliance with safety standards and performance requirements in each application sector.

Cost Comparison: Flame Retardant vs Standard

Flame retardant grade polycarbonate typically incurs a higher cost than standard grade due to the inclusion of specialized additives that enhance fire resistance. The price difference can range from 20% to 40%, influenced by the specific formulation and manufacturing process complexity. Despite the increased upfront expense, flame retardant polycarbonate provides significant safety benefits in applications requiring compliance with stringent fire safety regulations.

Choosing the Right Polycarbonate Grade for Your Project

Flame retardant grade polycarbonate offers enhanced fire resistance by incorporating specialized additives that reduce flammability and smoke generation compared to standard grade polycarbonate. Selecting the appropriate grade depends on project requirements such as compliance with fire safety regulations, application environment, and exposure to heat sources. Projects demanding stringent fire safety standards, like construction or electronics, benefit from flame retardant polycarbonate's superior performance, while standard grade suits general-use applications with lower fire risk.

Flame Retardant Grade vs Standard Grade Infographic

materialdif.com

materialdif.com