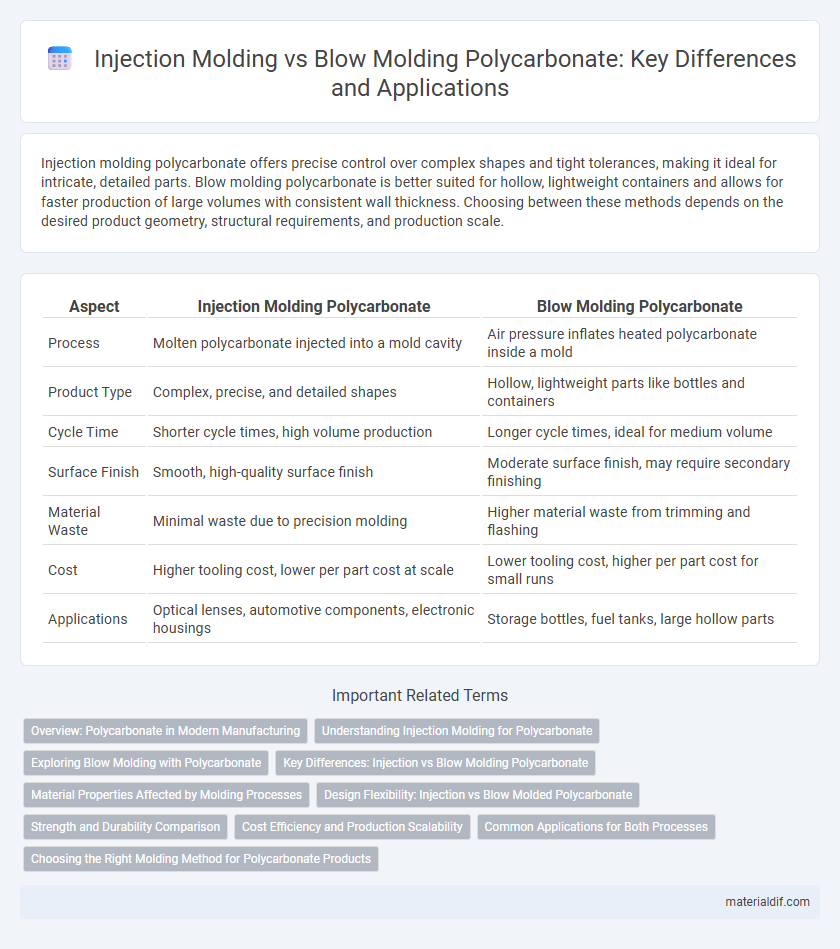

Injection molding polycarbonate offers precise control over complex shapes and tight tolerances, making it ideal for intricate, detailed parts. Blow molding polycarbonate is better suited for hollow, lightweight containers and allows for faster production of large volumes with consistent wall thickness. Choosing between these methods depends on the desired product geometry, structural requirements, and production scale.

Table of Comparison

| Aspect | Injection Molding Polycarbonate | Blow Molding Polycarbonate |

|---|---|---|

| Process | Molten polycarbonate injected into a mold cavity | Air pressure inflates heated polycarbonate inside a mold |

| Product Type | Complex, precise, and detailed shapes | Hollow, lightweight parts like bottles and containers |

| Cycle Time | Shorter cycle times, high volume production | Longer cycle times, ideal for medium volume |

| Surface Finish | Smooth, high-quality surface finish | Moderate surface finish, may require secondary finishing |

| Material Waste | Minimal waste due to precision molding | Higher material waste from trimming and flashing |

| Cost | Higher tooling cost, lower per part cost at scale | Lower tooling cost, higher per part cost for small runs |

| Applications | Optical lenses, automotive components, electronic housings | Storage bottles, fuel tanks, large hollow parts |

Overview: Polycarbonate in Modern Manufacturing

Polycarbonate plays a crucial role in modern manufacturing due to its high impact resistance, optical clarity, and thermal stability. Injection molding polycarbonate allows for precise, complex shapes with excellent surface finish, making it ideal for electronic housings and automotive components. Blow molding polycarbonate, on the other hand, is preferred for producing hollow parts like bottles and containers, emphasizing lightweight durability and consistent wall thickness.

Understanding Injection Molding for Polycarbonate

Injection molding of polycarbonate involves melting the thermoplastic resin and injecting it into a mold cavity where it cools and solidifies into a precise shape, enabling the production of complex geometries with high dimensional accuracy and surface finish. This process offers rapid cycle times and excellent mechanical properties like impact resistance and transparency, making it ideal for manufacturing intricate components such as automotive parts, electronic housings, and medical devices. Control over processing parameters such as temperature and injection pressure is critical to prevent defects like warping or degradation, ensuring high-quality finished polycarbonate products.

Exploring Blow Molding with Polycarbonate

Blow molding polycarbonate enables the production of hollow parts with high impact resistance and excellent optical clarity, making it ideal for containers and automotive components. This process offers superior material distribution and lightweight structures compared to injection molding, which is typically limited to solid, complex shapes. Exploring blow molding with polycarbonate expands design possibilities for transparent, durable, and lightweight products requiring uniform wall thickness and scalability in manufacturing.

Key Differences: Injection vs Blow Molding Polycarbonate

Injection molding polycarbonate produces precise, complex shapes with high dimensional accuracy and smooth surface finishes, ideal for intricate components and optical-quality parts. Blow molding polycarbonate creates hollow, lightweight, and large-volume products such as bottles and containers by inflating molten plastic inside a mold, emphasizing cost-efficient production for high-volume runs. Injection molding offers faster cycle times and better mechanical properties, whereas blow molding is preferred for economical manufacturing of hollow structures.

Material Properties Affected by Molding Processes

Injection molding polycarbonate produces parts with higher dimensional accuracy and improved surface finish due to controlled cooling rates, resulting in enhanced mechanical strength and impact resistance. Blow molding polycarbonate typically yields hollow structures with more uniform wall thickness but lower tensile strength and reduced clarity compared to injection-molded parts. The molding process influences the polymer chain orientation and residual stress levels, which directly affect the thermal stability and optical properties of polycarbonate products.

Design Flexibility: Injection vs Blow Molded Polycarbonate

Injection molding polycarbonate offers superior design flexibility by enabling intricate geometries, tight tolerances, and complex details that are often unattainable with blow molding. Blow molded polycarbonate is primarily suited for hollow and lightweight parts, limiting its ability to produce intricate shapes or fine surface details. This makes injection molding the preferred method for applications requiring precise features and higher structural integrity in polycarbonate components.

Strength and Durability Comparison

Injection molding polycarbonate produces parts with higher structural integrity and uniform strength due to precise control over material flow and cooling rates, making it ideal for complex, load-bearing components. Blow molding polycarbonate, while offering excellent impact resistance and flexibility, typically results in thinner walls and less consistent strength distribution, which may reduce overall durability under heavy mechanical stress. For applications demanding maximum toughness and long-term durability, injection molding is generally the preferred fabrication method over blow molding.

Cost Efficiency and Production Scalability

Injection molding polycarbonate offers superior cost efficiency for high-volume production runs due to faster cycle times and lower material waste compared to blow molding. Blow molding polycarbonate becomes more cost-effective for large, hollow parts and facilitates production scalability with simpler tooling adjustments for varying wall thicknesses. Manufacturers often select injection molding for complex, precise components and blow molding for lightweight, volumetric shapes to optimize overall production efficiency.

Common Applications for Both Processes

Injection molding polycarbonate is commonly used for manufacturing high-precision components such as automotive parts, medical devices, and electronic housings due to its ability to produce complex shapes with excellent dimensional accuracy. Blow molding polycarbonate is typically applied in creating hollow items like bottles, containers, and large industrial tanks where lightweight and impact resistance are essential. Both processes exploit polycarbonate's durability and clarity but cater to different product designs and volume requirements in diverse industries.

Choosing the Right Molding Method for Polycarbonate Products

Injection molding polycarbonate offers precise control over intricate shapes and higher dimensional accuracy, making it ideal for complex, high-strength components like optical lenses and medical devices. Blow molding polycarbonate excels in producing hollow, lightweight structures such as containers and bottles with faster cycle times and lower tooling costs. Selecting the right molding method depends on product geometry, production volume, and mechanical performance requirements specific to polycarbonate applications.

Injection Molding Polycarbonate vs Blow Molding Polycarbonate Infographic

materialdif.com

materialdif.com