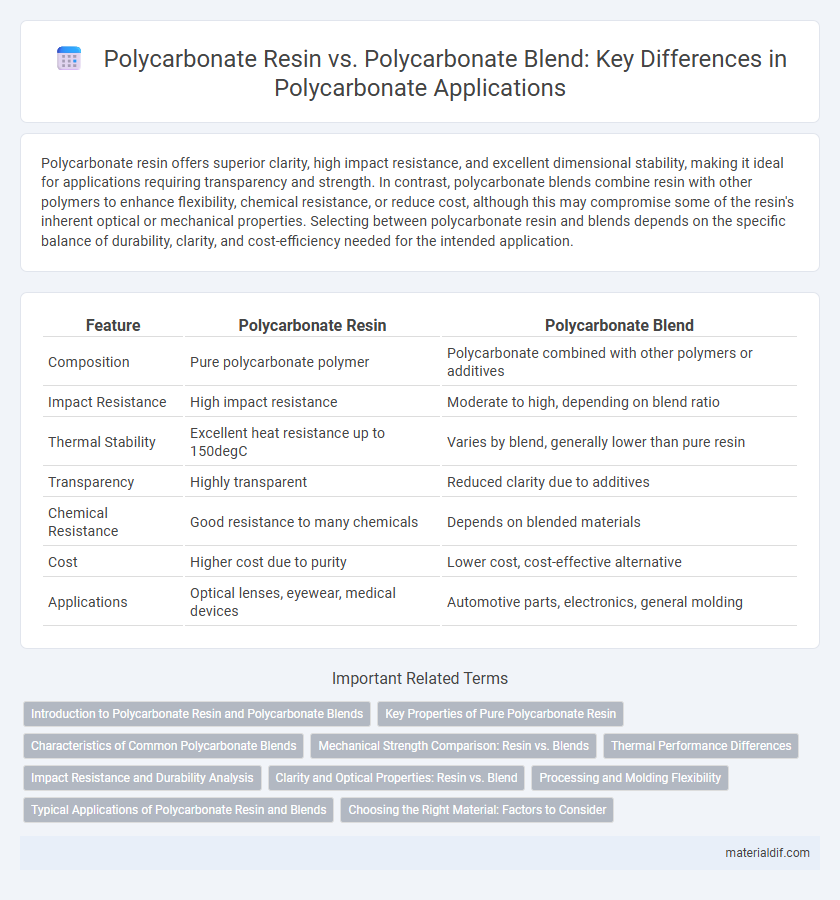

Polycarbonate resin offers superior clarity, high impact resistance, and excellent dimensional stability, making it ideal for applications requiring transparency and strength. In contrast, polycarbonate blends combine resin with other polymers to enhance flexibility, chemical resistance, or reduce cost, although this may compromise some of the resin's inherent optical or mechanical properties. Selecting between polycarbonate resin and blends depends on the specific balance of durability, clarity, and cost-efficiency needed for the intended application.

Table of Comparison

| Feature | Polycarbonate Resin | Polycarbonate Blend |

|---|---|---|

| Composition | Pure polycarbonate polymer | Polycarbonate combined with other polymers or additives |

| Impact Resistance | High impact resistance | Moderate to high, depending on blend ratio |

| Thermal Stability | Excellent heat resistance up to 150degC | Varies by blend, generally lower than pure resin |

| Transparency | Highly transparent | Reduced clarity due to additives |

| Chemical Resistance | Good resistance to many chemicals | Depends on blended materials |

| Cost | Higher cost due to purity | Lower cost, cost-effective alternative |

| Applications | Optical lenses, eyewear, medical devices | Automotive parts, electronics, general molding |

Introduction to Polycarbonate Resin and Polycarbonate Blends

Polycarbonate resin is a thermoplastic polymer known for its high impact resistance, optical clarity, and thermal stability, widely used in automotive, electronics, and construction industries. Polycarbonate blends combine pure polycarbonate resin with other polymers like ABS or polyester to enhance specific properties such as chemical resistance, flexibility, or processability. These blends offer tailored performance characteristics, making them suitable for diverse applications requiring improved durability or specialized mechanical traits.

Key Properties of Pure Polycarbonate Resin

Pure polycarbonate resin is characterized by excellent impact resistance, high optical clarity, and superior heat resistance up to 135degC. Its inherent toughness and dimensional stability make it ideal for applications requiring transparency and durability, such as optical lenses and protective gear. Unlike polycarbonate blends, pure resin offers consistent chemical resistance and low moisture absorption, ensuring reliable long-term performance.

Characteristics of Common Polycarbonate Blends

Polycarbonate blends combine polycarbonate resin with other polymers like acrylonitrile butadiene styrene (ABS) or polyethylene terephthalate glycol (PETG), enhancing impact resistance, chemical stability, and processability compared to pure polycarbonate resin. Common blends exhibit improved thermal resistance, increased flexibility, and superior surface finish, making them ideal for automotive, electronics, and consumer goods applications. These blends retain the inherent toughness and transparency of polycarbonate resin while addressing specific industry demands through tailored mechanical and chemical properties.

Mechanical Strength Comparison: Resin vs. Blends

Polycarbonate resin typically exhibits higher mechanical strength, including superior impact resistance and tensile strength, compared to polycarbonate blends. Blending polycarbonate with other polymers can enhance specific properties such as flexibility or chemical resistance but often results in a reduction of overall mechanical strength. Resin's uniform molecular structure contributes to its robustness in demanding applications, whereas blends trade off some strength for versatility.

Thermal Performance Differences

Polycarbonate resin exhibits superior thermal stability with a glass transition temperature (Tg) around 147degC, making it ideal for high-heat applications. Polycarbonate blends, often combined with other polymers like ABS or PETG, offer modified thermal properties, typically lowering the overall Tg and enhancing impact resistance but reducing maximum service temperature. Understanding these differences is crucial for selecting materials based on specific thermal performance requirements in industries like automotive and electronics.

Impact Resistance and Durability Analysis

Polycarbonate resin exhibits high impact resistance and maintains structural integrity under extreme stress, making it ideal for applications requiring robust durability. Polycarbonate blends often incorporate additives or other polymers to enhance specific properties like chemical resistance or flexibility but may slightly reduce pure impact resistance compared to the resin alone. Analysis shows that while blends provide tailored performance benefits, pure polycarbonate resin typically outperforms blends in long-term durability and impact absorption.

Clarity and Optical Properties: Resin vs. Blend

Polycarbonate resin offers superior clarity with high light transmittance, making it ideal for applications requiring exceptional optical properties such as lenses and eyewear. Polycarbonate blends may sacrifice some transparency due to additive materials but can improve impact resistance and chemical stability. The choice between resin and blend depends on the balance needed between optical clarity and enhanced mechanical performance.

Processing and Molding Flexibility

Polycarbonate resin offers superior processing and molding flexibility due to its excellent thermal stability and consistent melt flow properties, enabling precise injection molding and extrusion techniques. Polycarbonate blends incorporate other polymers, enhancing impact resistance or chemical properties but may require adjusted processing parameters to accommodate variations in melt viscosity and compatibility. These blends provide tailored molding options for specialized applications, balancing flexibility with performance demands in manufacturing.

Typical Applications of Polycarbonate Resin and Blends

Polycarbonate resin is widely utilized in optical lenses, electronic components, and automotive parts due to its high impact resistance, transparency, and thermal stability. Polycarbonate blends combine polycarbonate with other polymers, enhancing properties like chemical resistance and flexibility, making them ideal for applications in medical devices, consumer electronics, and industrial equipment. Both polycarbonate resin and blends offer tailored solutions for manufacturing durable, lightweight, and high-performance products across various industries.

Choosing the Right Material: Factors to Consider

Polycarbonate resin offers high clarity, impact resistance, and thermal stability, making it ideal for applications requiring transparency and durability. Polycarbonate blends incorporate additives or other polymers to enhance specific properties like chemical resistance, flexibility, or cost-effectiveness depending on the application needs. When choosing between polycarbonate resin and blends, factors such as mechanical performance, environmental exposure, processing requirements, and budget constraints should be carefully evaluated to ensure optimal material selection for targeted use.

Polycarbonate Resin vs Polycarbonate Blend Infographic

materialdif.com

materialdif.com