Thermoforming polycarbonate involves heating sheets to shape them into desired forms, providing cost-effective customization for medium-sized production runs and large, thin-walled parts. Injection molding polycarbonate offers high precision and repeatability, ideal for complex geometries and high-volume manufacturing with excellent structural integrity. Choosing between thermoforming and injection molding depends on the specific application, production volume, and design complexity of the polycarbonate product.

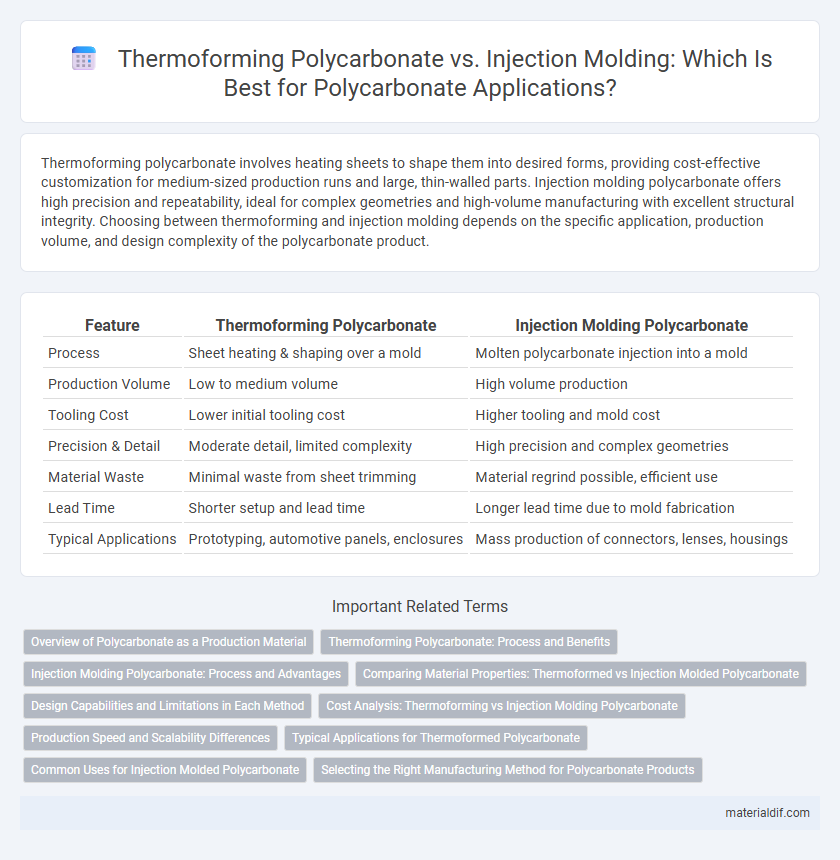

Table of Comparison

| Feature | Thermoforming Polycarbonate | Injection Molding Polycarbonate |

|---|---|---|

| Process | Sheet heating & shaping over a mold | Molten polycarbonate injection into a mold |

| Production Volume | Low to medium volume | High volume production |

| Tooling Cost | Lower initial tooling cost | Higher tooling and mold cost |

| Precision & Detail | Moderate detail, limited complexity | High precision and complex geometries |

| Material Waste | Minimal waste from sheet trimming | Material regrind possible, efficient use |

| Lead Time | Shorter setup and lead time | Longer lead time due to mold fabrication |

| Typical Applications | Prototyping, automotive panels, enclosures | Mass production of connectors, lenses, housings |

Overview of Polycarbonate as a Production Material

Polycarbonate is a durable, transparent thermoplastic widely used in both thermoforming and injection molding due to its high impact resistance and excellent dimensional stability. Thermoforming polycarbonate involves heating and shaping sheets, making it ideal for large, thin-walled parts, while injection molding allows for complex, precise geometries with tight tolerances. Its outstanding thermal resistance and optical clarity make polycarbonate a preferred material in automotive, electronic, and medical device manufacturing.

Thermoforming Polycarbonate: Process and Benefits

Thermoforming polycarbonate involves heating sheets of polycarbonate until pliable, then shaping them over molds to create precise, lightweight components with excellent optical clarity. This process offers faster turnaround times and lower tooling costs compared to injection molding, making it ideal for short production runs and prototyping. Thermoformed polycarbonate parts exhibit high impact resistance and UV stability, ensuring durability in various applications such as automotive glazing and protective covers.

Injection Molding Polycarbonate: Process and Advantages

Injection molding polycarbonate involves melting the polymer pellets and injecting the molten material into precision-engineered molds under high pressure, enabling complex shapes and fine details with tight tolerances. This process delivers superior mechanical properties, including high impact resistance, excellent dimensional stability, and enhanced optical clarity, making it ideal for producing durable automotive parts, electronic housings, and medical devices. The high production efficiency, low material waste, and capacity for automated mass production significantly reduce costs and improve consistency compared to thermoforming polycarbonate.

Comparing Material Properties: Thermoformed vs Injection Molded Polycarbonate

Thermoformed polycarbonate exhibits excellent clarity and impact resistance but tends to have lower dimensional stability compared to injection molded polycarbonate, which offers superior strength and precision due to higher cooling rates during processing. Injection molding results in polycarbonate parts with enhanced mechanical properties, including greater tensile strength and improved surface finish, making it ideal for complex, high-precision components. Thermoforming is better suited for large, simple shapes with moderate mechanical demands, while injection molding dominates applications requiring intricate detail and consistent material performance.

Design Capabilities and Limitations in Each Method

Thermoforming polycarbonate allows for rapid prototyping with large, shallow parts and offers flexibility in creating smooth, curved surfaces but is limited in producing intricate details and complex geometries. Injection molding polycarbonate excels in high precision, enabling intricate designs and complex shapes with consistent repeatability but involves higher upfront tooling costs and longer lead times. Choosing between these processes depends on the balance between design complexity, surface finish requirements, and production volume.

Cost Analysis: Thermoforming vs Injection Molding Polycarbonate

Thermoforming polycarbonate generally incurs lower initial tooling costs compared to injection molding due to simpler mold requirements, making it more cost-effective for small to medium production volumes. Injection molding, despite higher upfront investment in molds and machinery, offers superior cost efficiency for large-scale manufacturing through faster cycle times and material utilization. Evaluating production volume and part complexity is crucial to determining the most economically viable method between thermoforming and injection molding polycarbonate components.

Production Speed and Scalability Differences

Thermoforming polycarbonate allows faster production speeds for large, flat, or moderately complex shapes due to its simplified heating and forming processes, ideal for small to medium runs. Injection molding polycarbonate excels in scalability by enabling high-volume production with precise, complex geometries, thanks to automated, repeatable injection cycles. The choice between these methods depends on targeted production scale and design complexity, with injection molding offering superior scalability and thermoforming offering quicker turnaround for limited batches.

Typical Applications for Thermoformed Polycarbonate

Thermoformed polycarbonate is commonly used for applications requiring lightweight, transparent protective barriers such as face shields, signage, and machine guards due to its excellent impact resistance and optical clarity. Its ability to be shaped into large, complex parts with consistent thickness makes it ideal for automotive interior panels and skylights. This process is preferred for prototypes and low-to-medium volume productions where design flexibility and cost efficiency are critical.

Common Uses for Injection Molded Polycarbonate

Injection molded polycarbonate is widely used in producing complex, high-precision components such as automotive parts, medical devices, and electronic enclosures due to its excellent dimensional stability and strength. This manufacturing process enables mass production of intricate shapes with tight tolerances, making it ideal for consumer electronics, optical lenses, and safety helmets. The versatility of injection molding allows for the integration of multiple features in a single component, enhancing product durability and performance.

Selecting the Right Manufacturing Method for Polycarbonate Products

Thermoforming polycarbonate is ideal for producing large, lightweight, and transparent parts with moderate detail, offering lower tooling costs and faster prototyping compared to injection molding. Injection molding excels in creating complex, high-precision polycarbonate components with excellent structural integrity and consistent repeatability, making it suitable for high-volume production. Selecting the right manufacturing method depends on factors such as product design complexity, production volume, surface finish requirements, and cost constraints.

Thermoforming Polycarbonate vs Injection Molding Polycarbonate Infographic

materialdif.com

materialdif.com