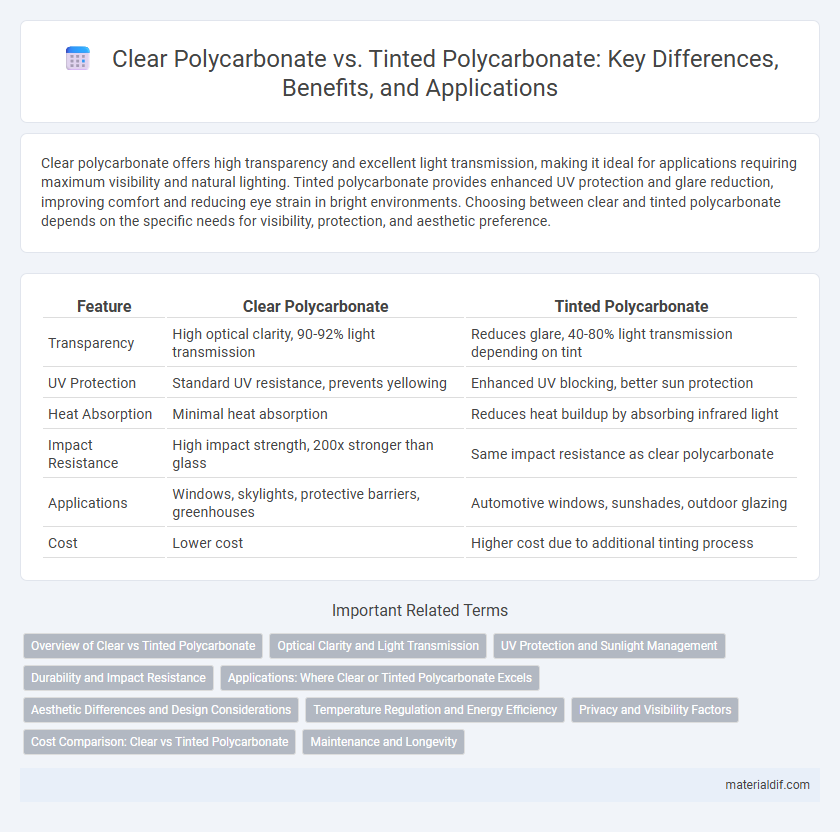

Clear polycarbonate offers high transparency and excellent light transmission, making it ideal for applications requiring maximum visibility and natural lighting. Tinted polycarbonate provides enhanced UV protection and glare reduction, improving comfort and reducing eye strain in bright environments. Choosing between clear and tinted polycarbonate depends on the specific needs for visibility, protection, and aesthetic preference.

Table of Comparison

| Feature | Clear Polycarbonate | Tinted Polycarbonate |

|---|---|---|

| Transparency | High optical clarity, 90-92% light transmission | Reduces glare, 40-80% light transmission depending on tint |

| UV Protection | Standard UV resistance, prevents yellowing | Enhanced UV blocking, better sun protection |

| Heat Absorption | Minimal heat absorption | Reduces heat buildup by absorbing infrared light |

| Impact Resistance | High impact strength, 200x stronger than glass | Same impact resistance as clear polycarbonate |

| Applications | Windows, skylights, protective barriers, greenhouses | Automotive windows, sunshades, outdoor glazing |

| Cost | Lower cost | Higher cost due to additional tinting process |

Overview of Clear vs Tinted Polycarbonate

Clear polycarbonate offers maximum light transmission with excellent impact resistance, making it ideal for applications requiring transparency and visibility, such as safety shields and eyewear. Tinted polycarbonate reduces glare and UV exposure while providing enhanced privacy and aesthetic appeal, suited for automotive windows and outdoor enclosures. Both types maintain durability and thermal stability, but choice depends on the balance between light clarity and protective shading needs.

Optical Clarity and Light Transmission

Clear polycarbonate offers superior optical clarity with light transmission rates up to 90%, making it ideal for applications requiring maximum visibility and natural light. Tinted polycarbonate reduces glare and UV exposure by filtering sunlight, typically transmitting between 15% to 70% of light depending on the tint level. Both types provide impact resistance, but clear polycarbonate excels in transparency, while tinted versions enhance comfort and protection in bright environments.

UV Protection and Sunlight Management

Clear polycarbonate offers excellent UV protection with high light transmission, making it ideal for applications requiring maximum natural light while blocking harmful ultraviolet rays. Tinted polycarbonate significantly reduces glare and heat by absorbing a broader spectrum of sunlight, enhancing comfort and energy efficiency in environments exposed to intense sunlight. Both materials provide durable UV resistance, but tinted polycarbonate excels in sunlight management by minimizing glare and controlling solar heat gain.

Durability and Impact Resistance

Clear polycarbonate offers excellent transparency while maintaining high durability and impact resistance, making it ideal for applications requiring visibility and toughness. Tinted polycarbonate, infused with UV inhibitors, enhances protection against sunlight degradation and reduces glare without significantly compromising structural integrity. Both versions provide superior impact resistance compared to glass, but tinted polycarbonate delivers added durability in outdoor settings by minimizing UV-related wear.

Applications: Where Clear or Tinted Polycarbonate Excels

Clear polycarbonate excels in applications requiring maximum light transmission such as protective glazing, eyewear lenses, and greenhouses, where visibility and optical clarity are crucial. Tinted polycarbonate is ideal for automotive windows, outdoor roofing, and privacy screens, as it reduces glare and blocks harmful UV rays while enhancing aesthetics. Both materials provide high impact resistance and durability, making them versatile choices for safety and architectural uses.

Aesthetic Differences and Design Considerations

Clear polycarbonate offers high transparency and natural light transmission, making it ideal for applications requiring visibility and clarity, such as windows and display panels. Tinted polycarbonate reduces glare and UV radiation, enhancing comfort and reducing heat buildup, which benefits outdoor and automotive designs. Design considerations include balancing aesthetic goals with functional needs, where clear sheets emphasize brightness and openness, while tinted sheets provide privacy and stylistic variation.

Temperature Regulation and Energy Efficiency

Clear polycarbonate allows maximum natural light transmission, reducing the need for artificial lighting and lowering energy usage during daylight hours. Tinted polycarbonate blocks a significant portion of solar heat, enhancing indoor temperature regulation and reducing cooling costs in warmer climates. The choice between clear and tinted polycarbonate directly impacts energy efficiency by balancing light penetration with solar heat gain control.

Privacy and Visibility Factors

Clear polycarbonate offers maximum visibility and transparency, making it ideal for applications requiring unobstructed views and natural light transmission. Tinted polycarbonate enhances privacy by limiting visibility from the outside while still allowing adequate light to pass through, suitable for areas needing discretion without sacrificing brightness. Both options provide UV protection and impact resistance, but selection depends on balancing privacy needs against visibility preferences in specific environments.

Cost Comparison: Clear vs Tinted Polycarbonate

Clear polycarbonate generally has a lower cost compared to tinted polycarbonate due to simpler manufacturing processes and lower demand for specialty colorants. Tinted polycarbonate often incurs higher prices because of added pigments or dyes, which require additional materials and processing steps. The price difference varies by tint intensity and brand, with darker or custom tints typically commanding premium rates.

Maintenance and Longevity

Clear polycarbonate offers excellent UV resistance and requires minimal cleaning to maintain transparency, making it ideal for applications needing maximum light transmission. Tinted polycarbonate provides enhanced protection against glare and heat, which can reduce surface degradation and extend the material's lifespan in harsh environments. Both types benefit from regular washing with mild soap and water to prevent scratching and prolong durability.

Clear Polycarbonate vs Tinted Polycarbonate Infographic

materialdif.com

materialdif.com